Multi-process production method, application and system of ready-made and ready-to-sell food based on communication control

A production method and multi-process technology, applied in general control systems, control/regulation systems, applications, etc., can solve the problem of fully automatic coffee that requires manual or mechanical arms to continuously operate control buttons or constantly touch the touch screen machine to send commands; taking iced coffee as an example, the manual or robotic arm touches the cup-taking button to control the cup-taking setting, long accumulation time, and long time required for coffee, so as to shorten the food processing cycle and solve the problem of long waiting time and food The effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

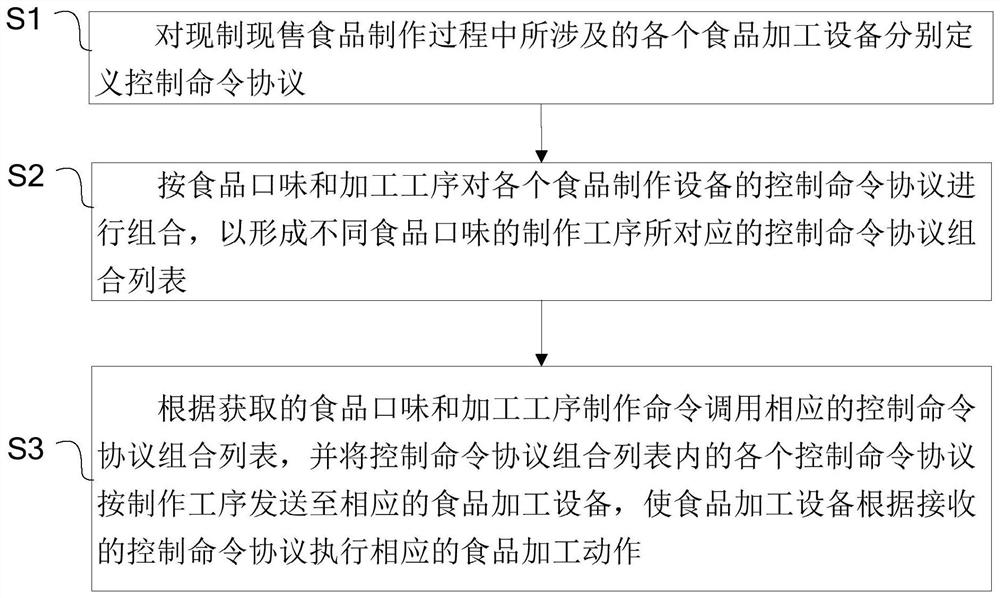

[0037] This example provides a multi-process production method for freshly prepared and sold food based on communication control. For the flow chart, please refer to figure 1 , including the following steps.

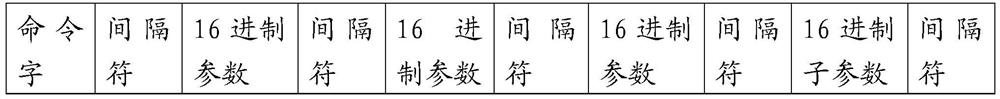

[0038] S1: Define the control command protocol for each food processing equipment involved in the process of preparing and selling food.

[0039] S2: Combining the control command protocols of each food processing equipment according to the food taste and processing procedures to form a combination list of control command protocols corresponding to the processing procedures of different food tastes.

[0040]Different food tastes have different processing procedures. For example, some food production requires a heating process, while some food production requires a refrigeration process. Therefore, this example performs corresponding processing procedures for different types of food flavors. Combination of control command protocols for food processing equipment to form a...

Embodiment 2

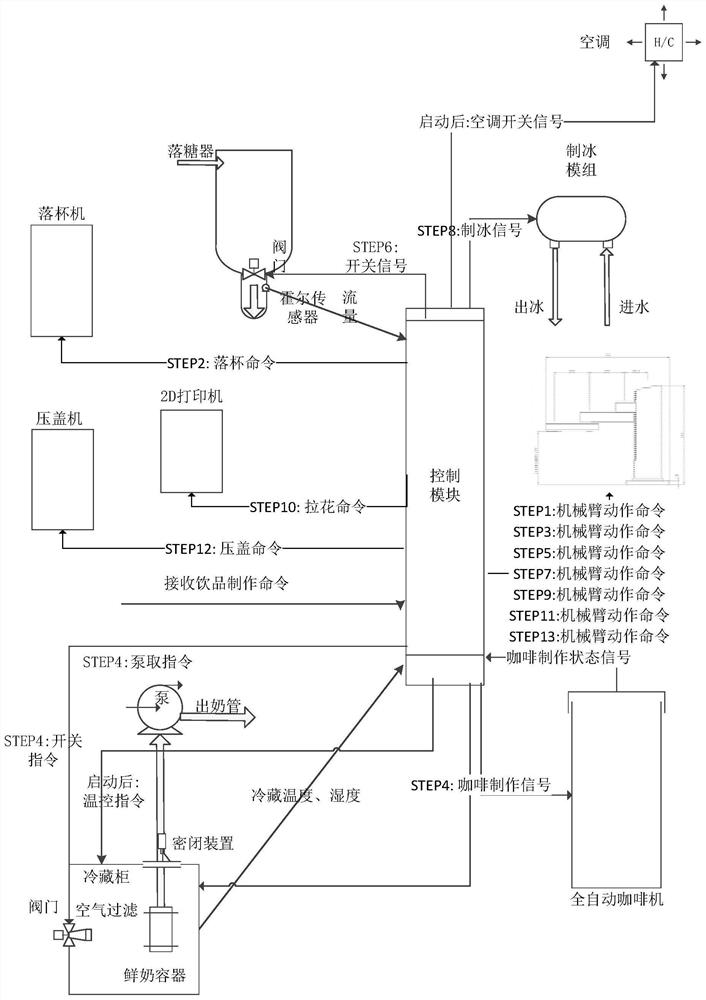

[0053] Based on Example 1, this example provides the application of the multi-process production method of ready-made and sold food in Example 1 in coffee production, which specifically includes the following steps.

[0054] S100: Define control command protocols for each processing equipment involved in the process of making coffee for sale on-the-go.

[0055] Due to the complex process involved in the specific production of coffee, there are many types of corresponding processing equipment. For example, processing equipment includes but is not limited to robotic arms, flower drawing machines, capping machines, fresh milk adding devices, ice making devices, falling Sugar device, coffee machine, air conditioner, cup dropping machine, refrigerator, etc., to realize the functions of corresponding processing equipment.

[0056] In addition to defining the control command protocol, it also includes defining the status command protocol and confirmation command protocol for each pro...

Embodiment 1 Embodiment 2

[0108] Based on Embodiment 1 and Embodiment 2, this example provides a communication-based control-based multi-process production system for ready-made and sold food, including:

[0109] The upper computer is used for human-computer interaction to obtain the production orders of food taste and processing procedures;

[0110] The control module is respectively signal-connected with each food processing equipment involved in the food production process, and is used to send commands to the corresponding food processing equipment according to the food taste and the production order of the processing procedure issued by the host computer:

[0111] Specifically, the control module stores several control command protocol combination lists formed by combining the control command protocols of various food processing equipment according to different food tastes and processing procedures. The control module makes command calls according to the acquired food tastes and processing procedure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com