A LED drive circuit and a dimming control method thereof

A LED drive and circuit technology, applied in the field of power electronics, can solve problems such as narrow dimming range, disconnection of SCR for maintaining current, flickering of LED lights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

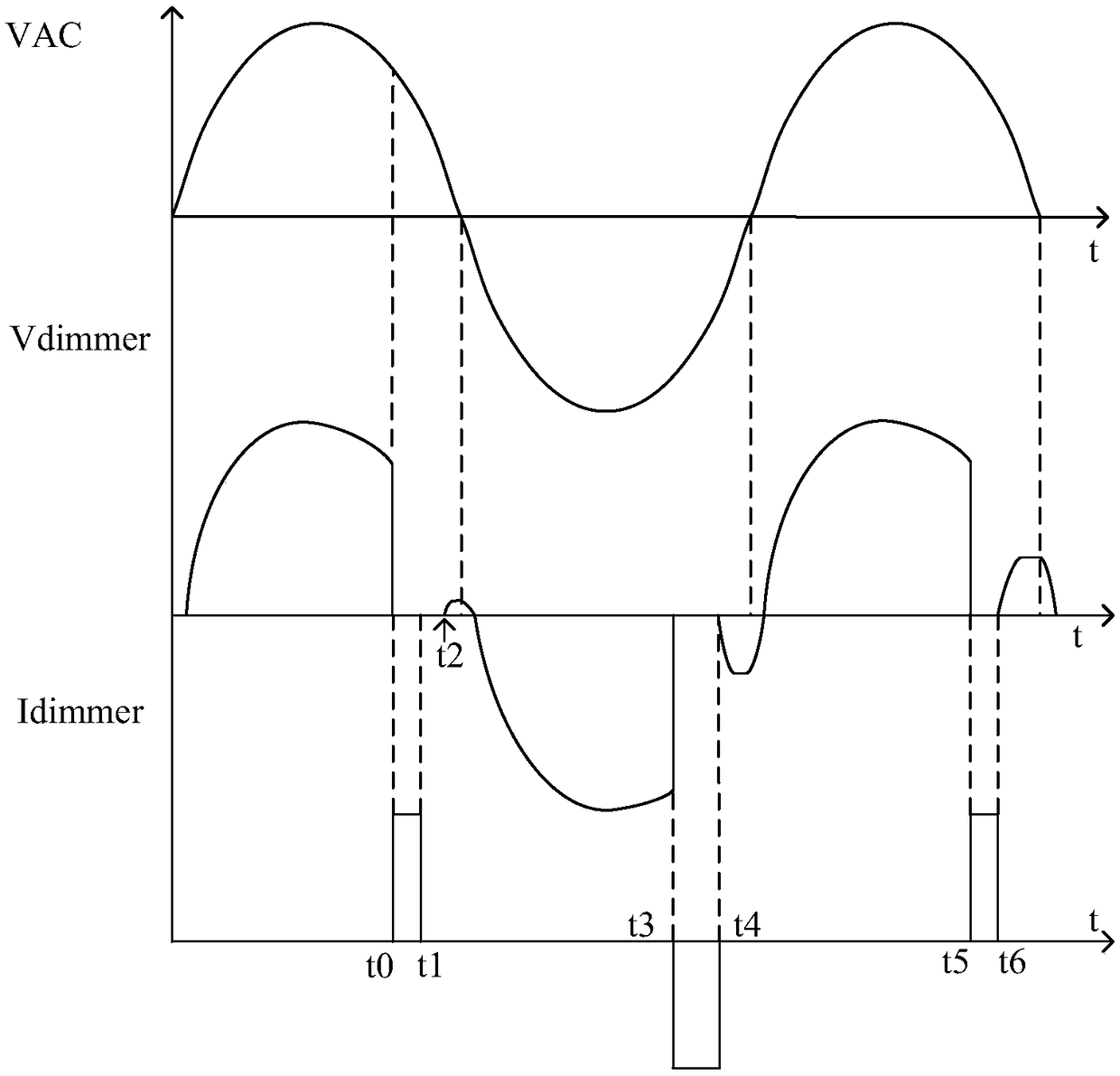

[0059] In the present application, the term "chopping period" refers to a period of time when the DC bus voltage is lower than the fourth reference value and the thyristor of the dimmer is in an off state.

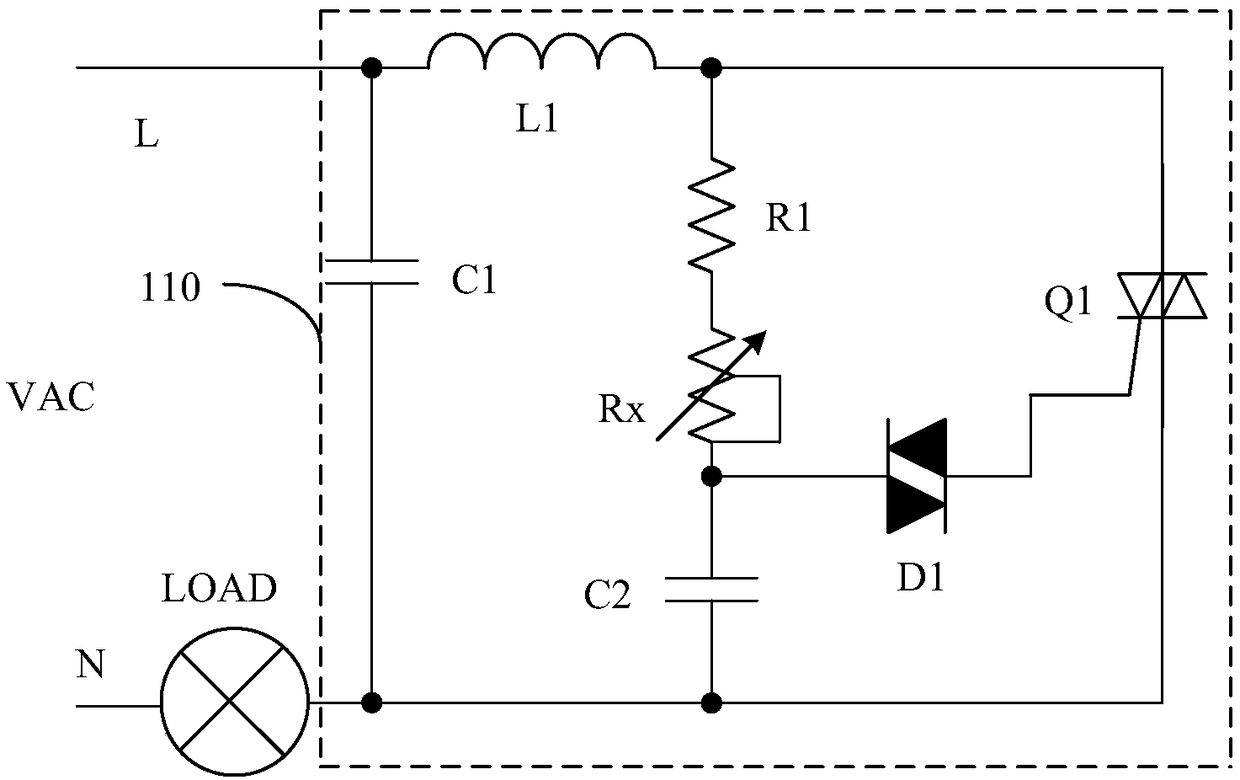

[0060] figure 1 A schematic circuit diagram of a thyristor dimming control system according to the prior art is shown. The thyristor dimming control system includes a dimmer 110 and a load LOAD. The dimmer 110 includes a capacitor C1, an inductor L1, a resistor R1, a variable resistor Rx, a capacitor C2, a bidirectional voltage regulator D1, and a thyristor Q1. The load LOAD is, for example, an incandescent lamp or an LED driving circuit.

[0061] like figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com