Mutton chop cutting machine

A technology of cutting machine and lamb chops, which is applied in slaughtering, meat processing equipment, food science, etc. It can solve the problems of inconvenient processing, high work intensity, uneven cutting, etc., and achieve the reduction of broken pieces, beautiful appearance and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

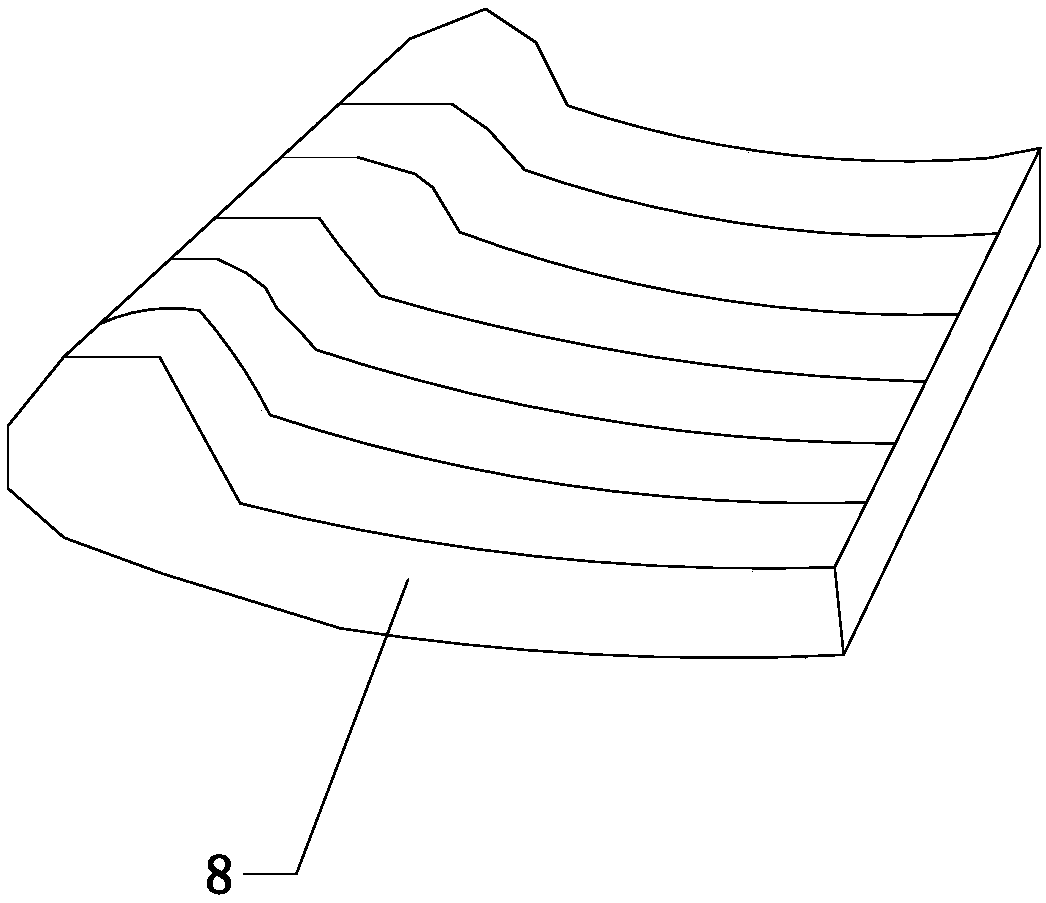

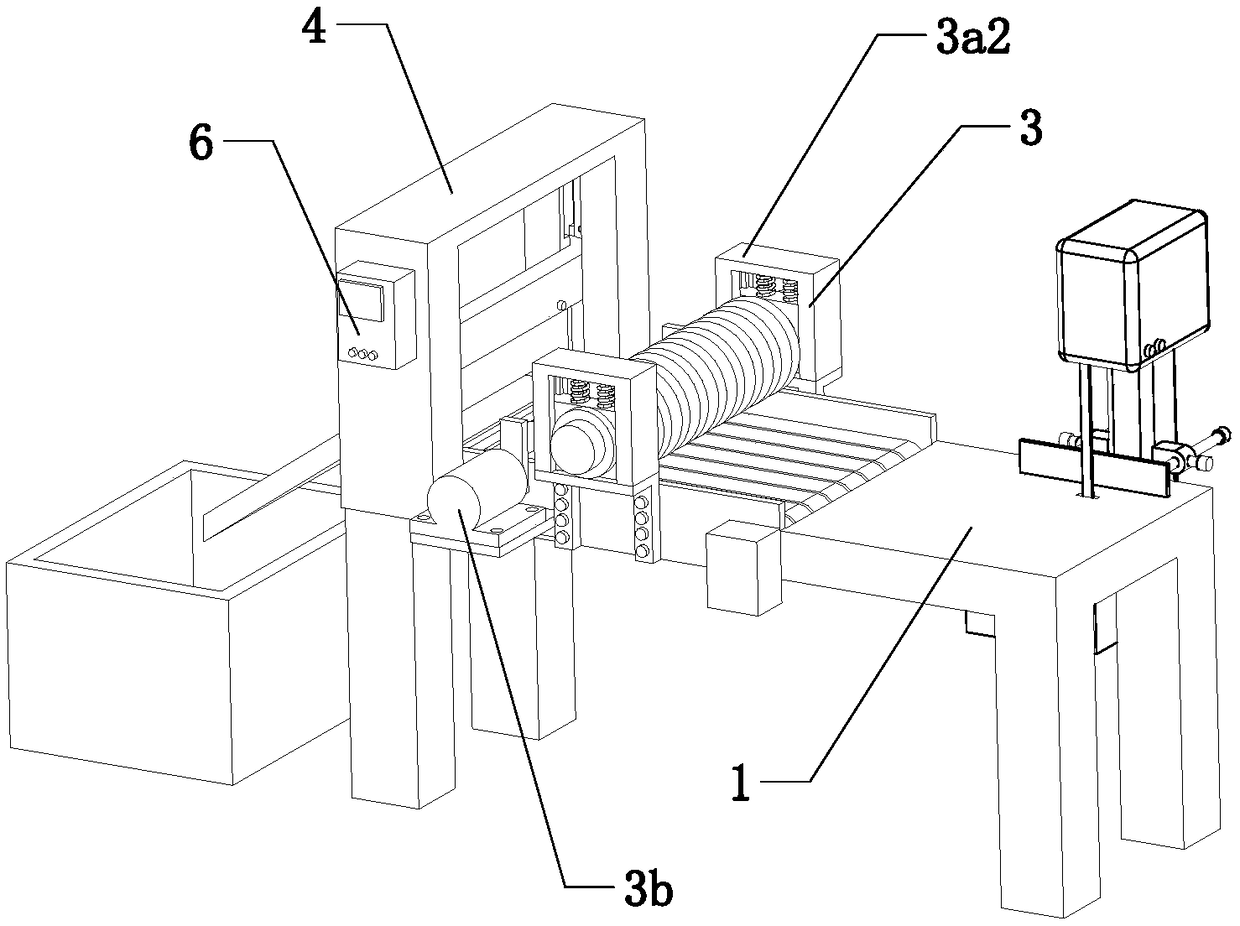

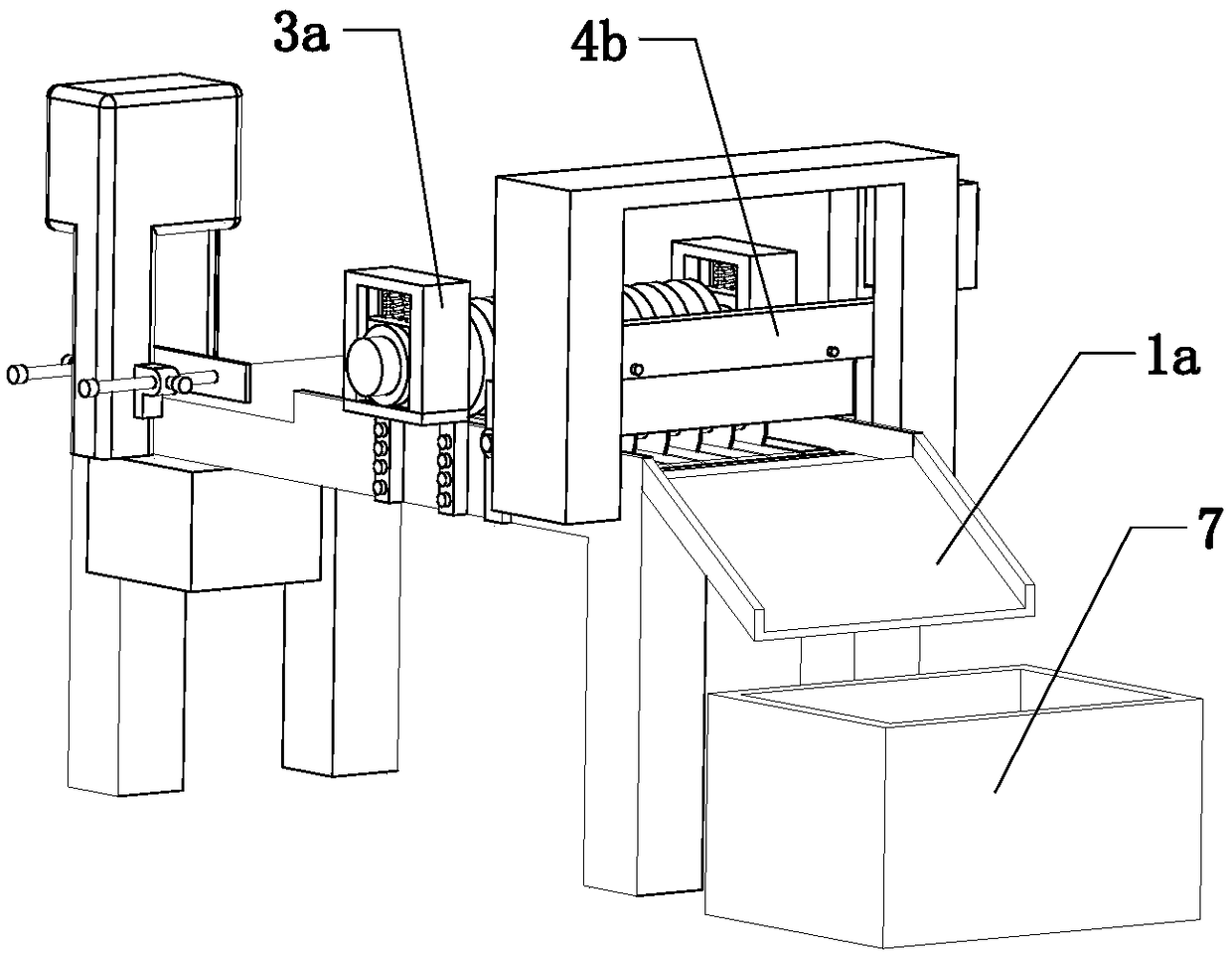

[0025] refer to Figure 1 to Figure 9 A kind of lamb chops cutting machine shown, comprises machine table 1, also comprises the first cutting device 2, the second cutting device 3, the 3rd cutting device 4 and conveyer belt 5, described first cutting device 2, the second cutting device 3. The third cutting device 4 and the conveyor belt 5 are all installed on the machine table 1, the first cutting device 2, the third cutting device 4 and the conveyor belt 5 are arranged in sequence along the conveying direction of the conveyor belt 5, and the second cutting device The device 3 is located above the conveyor belt 5, the second cutting device 3 includes a compression and expansion assembly 3a and a second cutting assembly 3b, and the compression and expansion assembly 3a and the second cutting assembly 3b are along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com