Multi-stage electromagnetic induction heating system used for low temperature tobacco

A technology of electromagnetic induction heating and electromagnetic induction, which is applied to tobacco, smoker's products, applications, etc., can solve the problems of reducing the difficulty of electromagnetic induction low-temperature tobacco preparation, reducing the appearance production requirements of low-temperature tobacco, and uneven low-temperature tobacco, and achieving uniform heating. , to increase the sense of satisfaction, the effect of sufficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

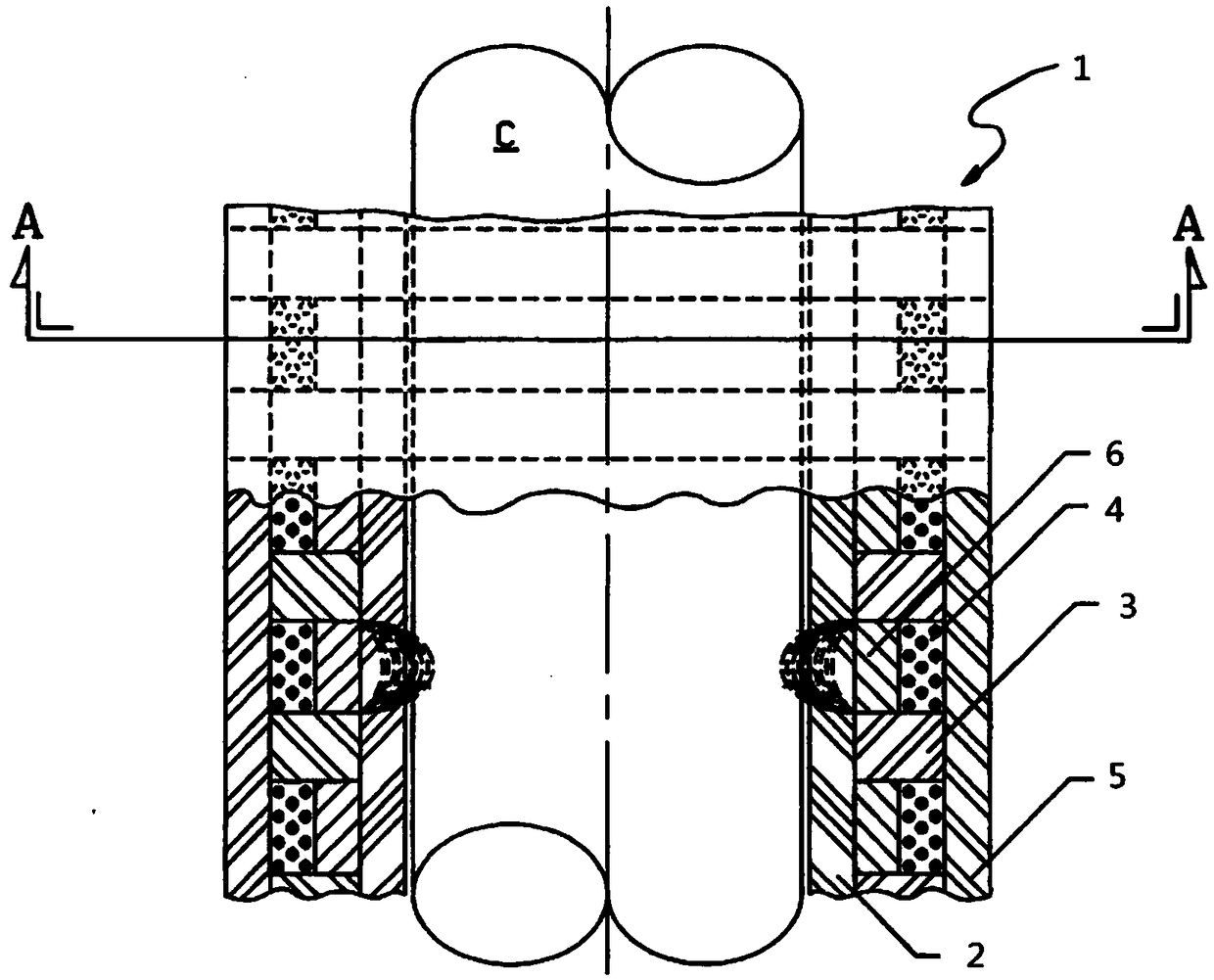

[0033] (1) Low-temperature cigarettes use paper to wrap the electromagnetic induction receiving medium layer, and the medium layer is then wrapped with low-temperature tobacco. The low-temperature tobacco does not contain a structural model of electromagnetic induction receiving medium. The dielectric layer adopts 0.07mm iron foil. The low-temperature cigarette adopts a standard cylindrical cigarette with a diameter of 5.4mm as the outer dimension, and sets the diameter size of the electromagnetic induction heat source, annular shield, external shield, electromagnetic pole piece, and inner wall to match the standard cylindrical cigarette with a diameter of 5.4mm.

[0034] (2) The electromagnetic induction heat source is calculated according to the standard smoke of 5.4mm to suck 9 mouths, and one electromagnetic induction heat source can be used to suck 3 mouths of low-temperature tobacco, so three electromagnetic induction heat sources are used, each containing 1 ferrite electro...

Embodiment 2

[0041] (1) The low-temperature cigarette adopts the structure mode in which the electromagnetic induction receiving medium is scattered inside the low-temperature tobacco, and the periphery is no longer wrapped with a medium layer. The heating medium adopts cylindrical aluminum particles with a diameter of 1 mm and a length of 3 mm. The low-temperature cigarette adopts a standard cylindrical cigarette with a diameter of 7.8mm as the outer dimension, and sets the diameter size of the electromagnetic induction heat source, annular shield, external shield, electromagnetic pole piece, and inner wall to match the standard cylindrical cigarette of 7.8mm.

[0042] (2) The electromagnetic induction heat source is calculated based on 15 puffs of standard smoke of 7.8mm, and one electromagnetic induction heat source can be used to suck 3 puffs of low-temperature tobacco. Therefore, 5 electromagnetic induction heat sources are used, each containing 1 ferrite electromagnetic pole sheet an...

Embodiment 3

[0049] This embodiment is the same as Embodiment 2, the difference is only in:

[0050] (1) Low-temperature cigarettes use paper to wrap the electromagnetic induction receiving medium layer, and the medium layer is then wrapped with low-temperature tobacco. The low-temperature tobacco contains a combined structural model of electromagnetic induction receiving medium.

[0051] (2) The annular shield is made of metal iron as its material.

[0052] The multi-stage electromagnetic induction heating system with a diameter of 7.8 mm prepared in this example adopts a combined structure of electromagnetic induction receiving medium outsourcing and internal dispersion. Under the same magnetic field strength, the heating speed is faster, but each time an electromagnetic induction heat source is turned on , it is difficult to maintain the suction experience of 3 puffs, but the puffing experience of 2 puffs can be guaranteed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com