Working method of uniform rust-removing and paint-spraying device for pipeline

A working method and pipeline technology, applied in the direction of spraying device, liquid spraying device, device for coating liquid on the surface, etc., can solve the problems of reduced work efficiency, rust removal, complicated painting equipment, insufficient pipeline clamping force, etc. Rapid rust removal and painting, good effect of rust removal and painting, and the effect of speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

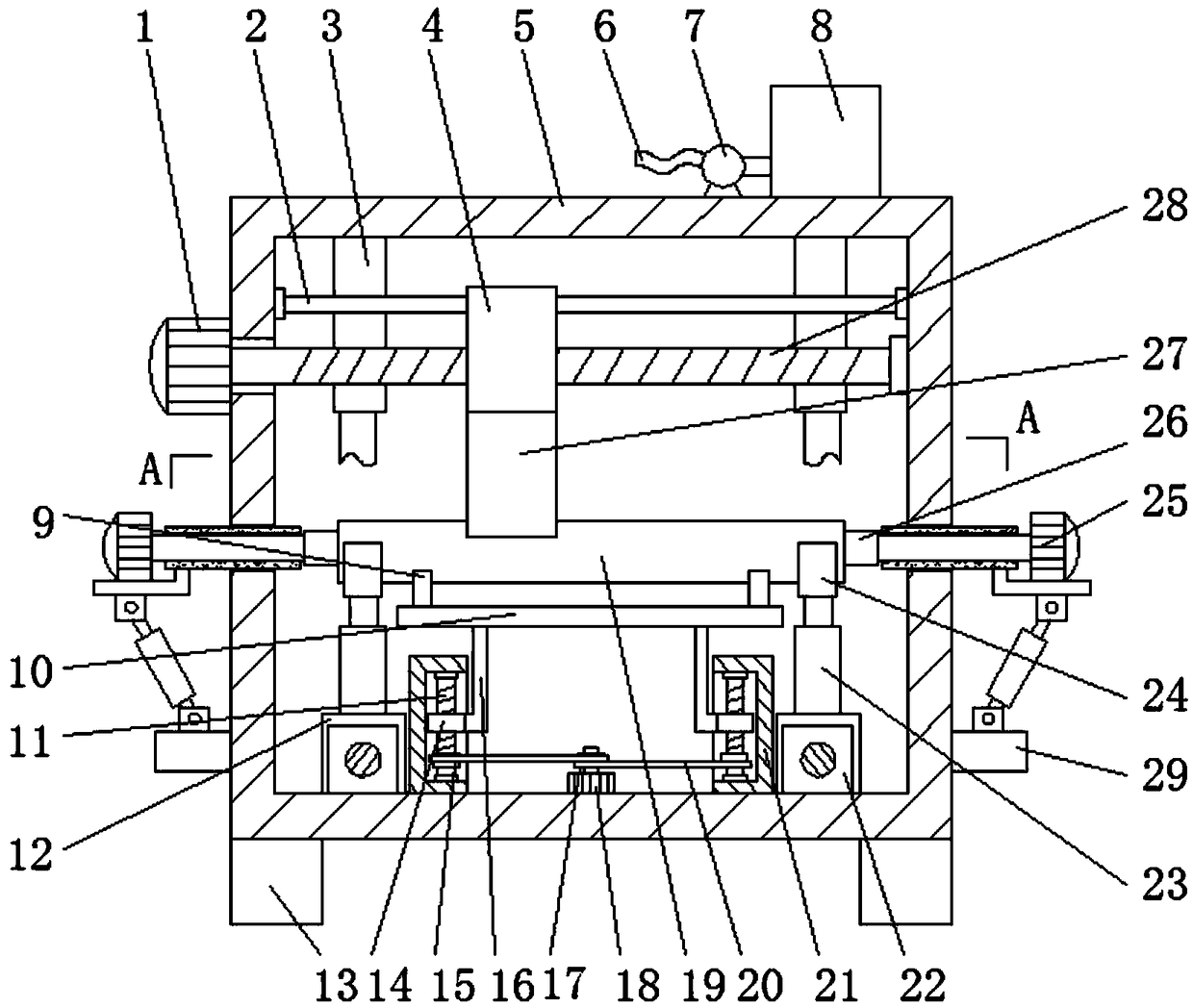

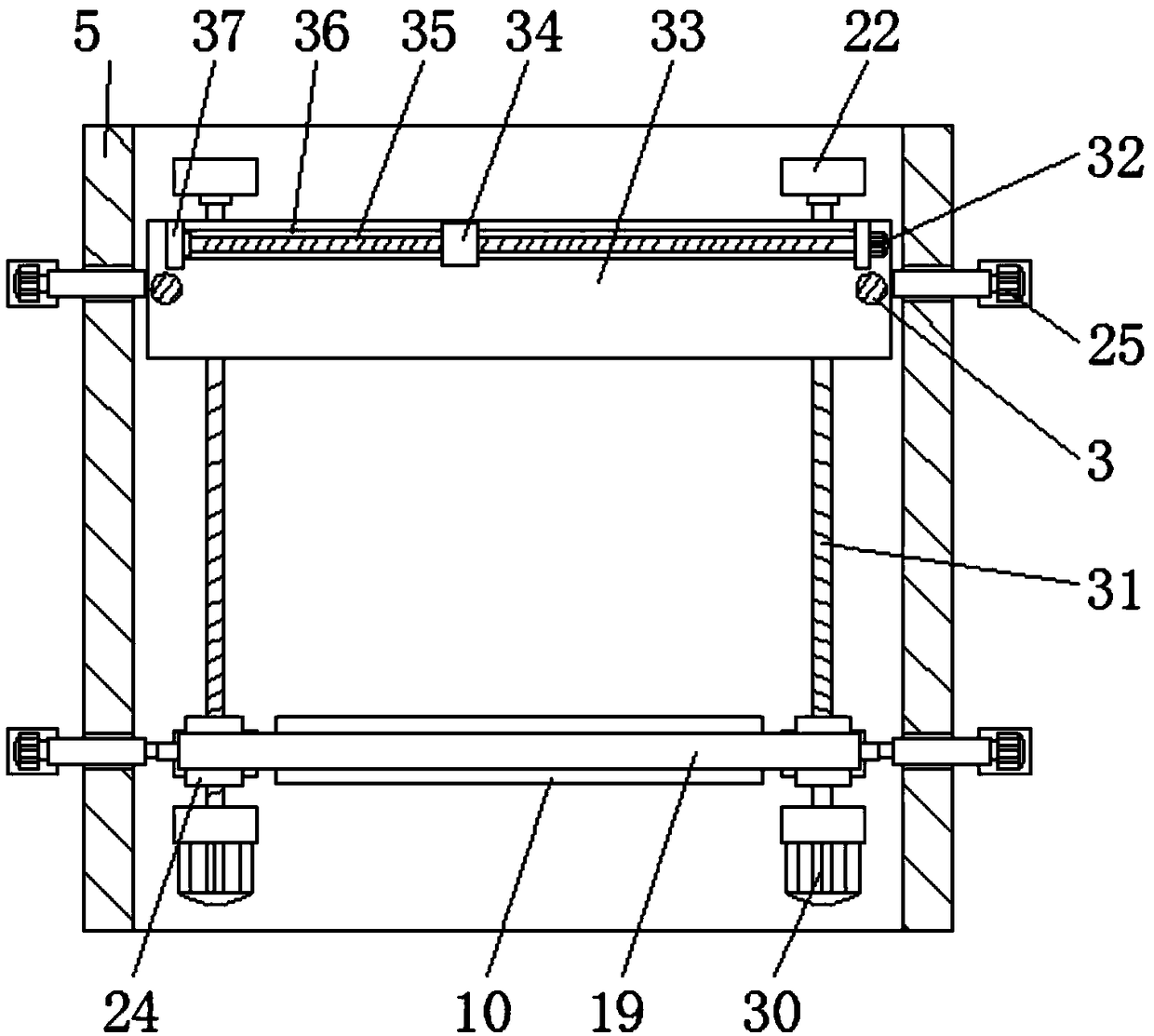

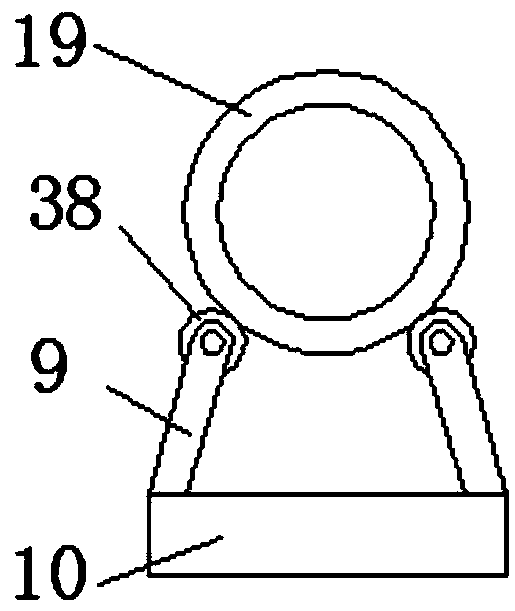

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0027] refer to Figure 1-7 , a uniform rust removal and painting device for pipelines, including a housing 5, a guide rod 2 is installed horizontally inside the housing 5, and the guide rod 2 runs through the first threaded slider 4, and can guide the first threaded slider 4 The effect of preventing the first threaded slider 4 from shifting during the movement.

[0028] Both sides of the lower surface of the housing 5 are fixedly equipped with supporting feet 13, and rubber pads are installed on the lower surface of the supporting feet 13. On the one hand, the device is isolated from the ground.

[0029]A paint pump 7 and a paint tank 8 are installed on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com