Horizontal converting furnace body butt welding method for non-ferrous metal smelting

A non-ferrous metal and blowing furnace technology, which is applied in the field of butt welding of horizontal blowing furnaces for non-ferrous metal smelting, can solve the problems of scrapped furnace body, long cycle and large investment, shorten the construction period and increase the output. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for butt welding a horizontal blowing furnace body for non-ferrous metal smelting, comprising the following steps:

[0029] Cutting the head: the head at one end of the old furnace body is cut off by segmented uniform cutting, and the cut on the old furnace body is polished to obtain the pretreated old furnace body;

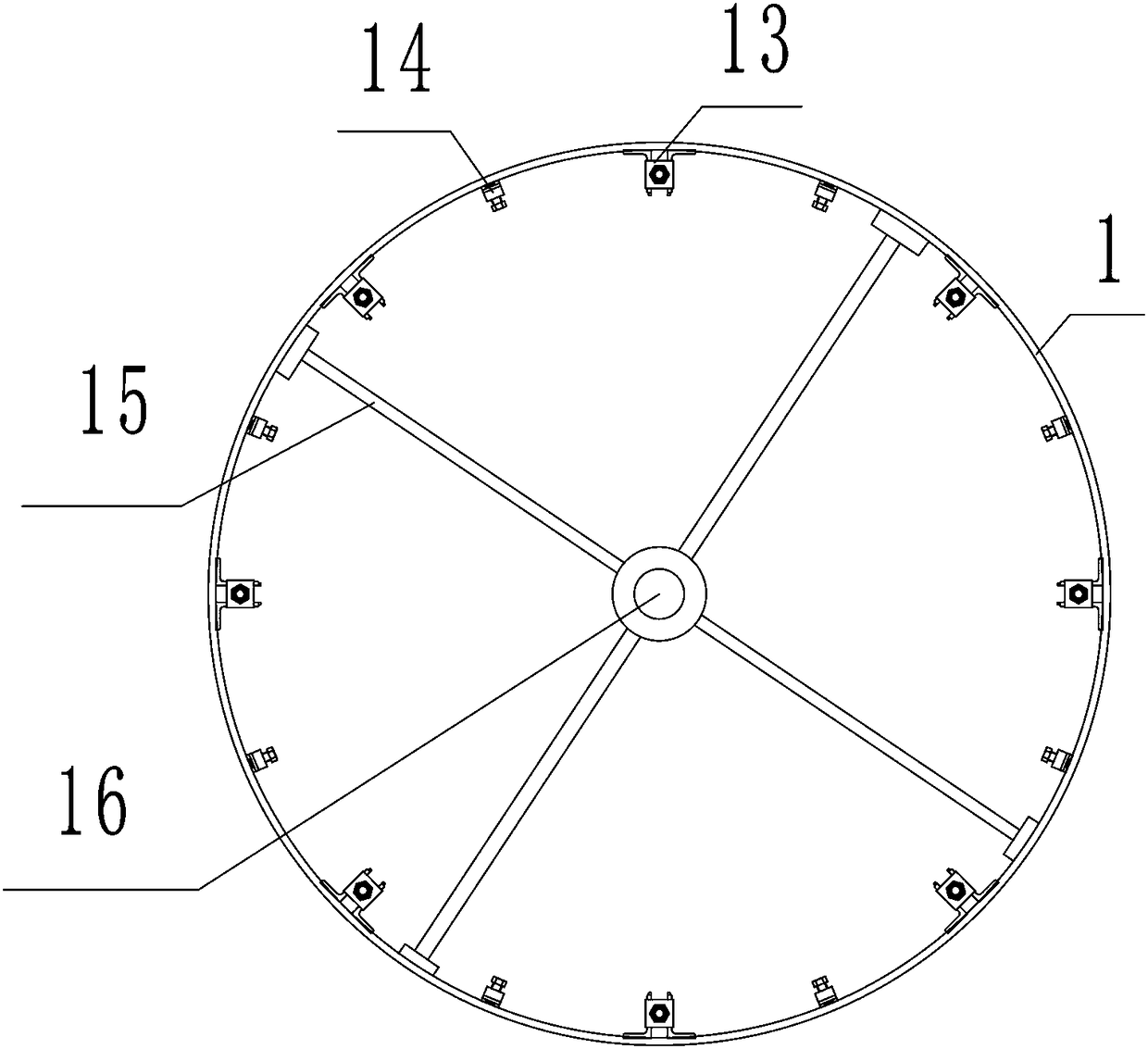

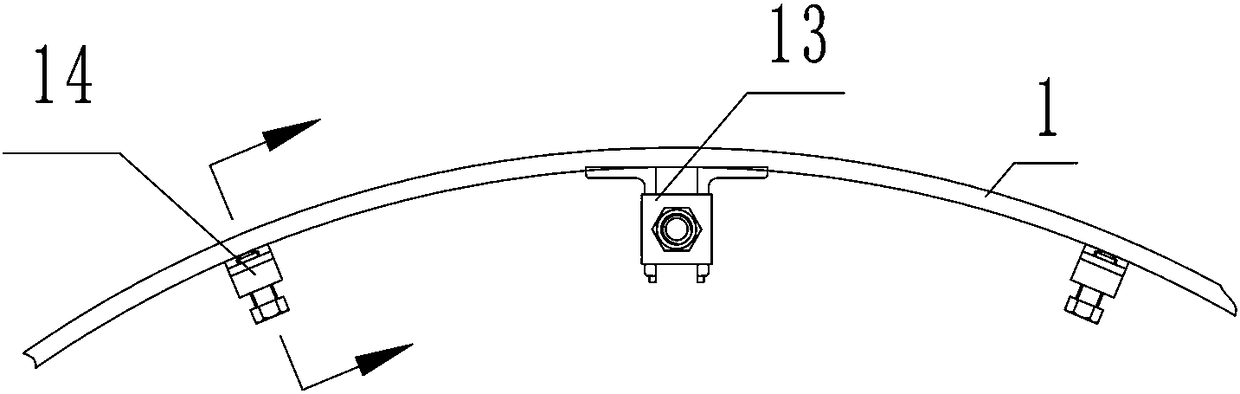

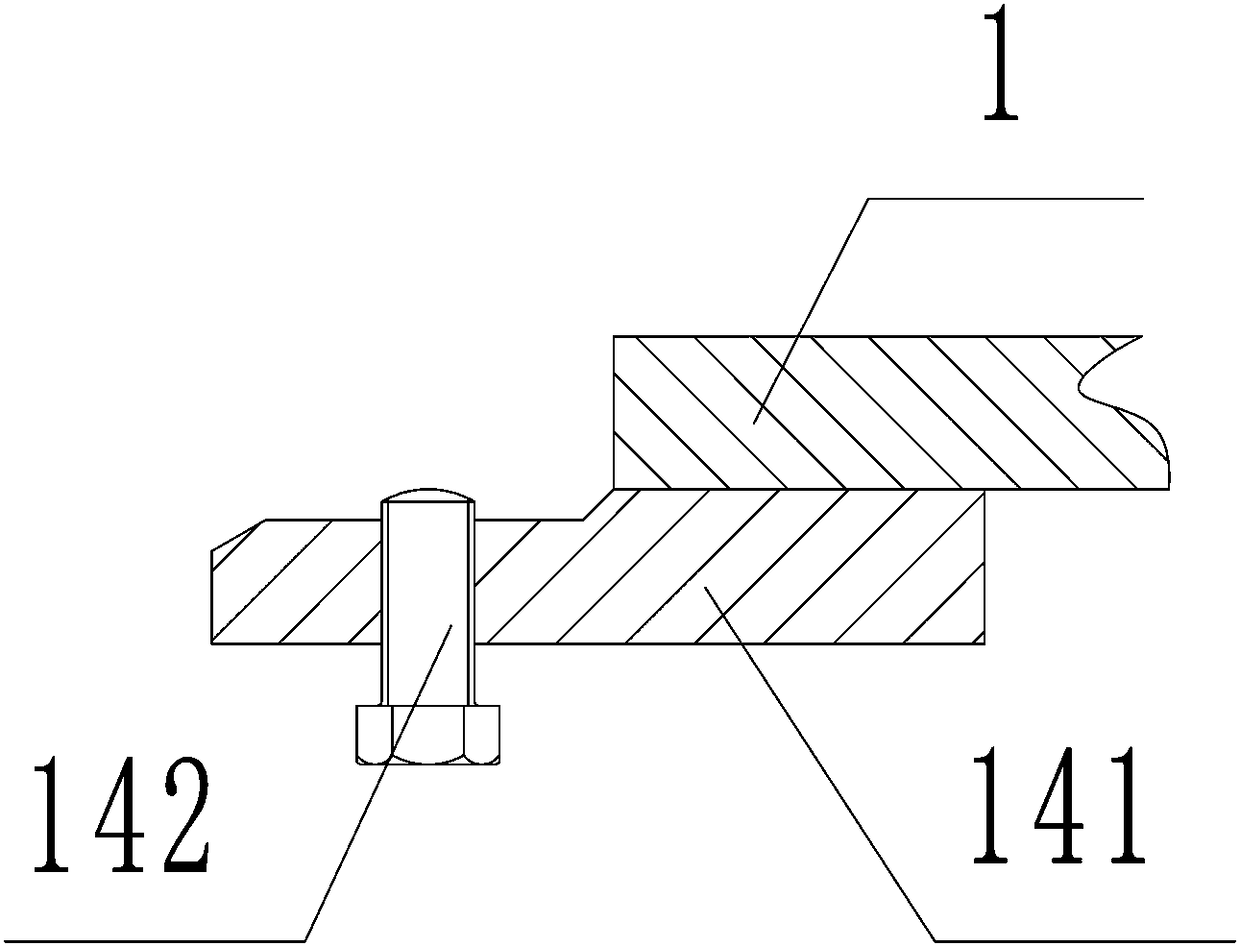

[0030] Pre-positioning: a laser positioning device is erected in the center of the furnace body cavity of the pre-treated old furnace body, and multiple fine-tuning mechanisms and multiple pre-positioning linkage mechanisms are suspended on the welding section of the pre-treated old furnace body. An alignment bracket is erected at the center of the cavity of the increased furnace body, and by adjusting the relative position between the pretreated old furnace body and the newly added furnace body, one end of the fine-tuning mechanism and the pre-positioning connecting rod One end of the mechanism enters the cavity of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com