FRP tank body flexible grinding device

A tank and flexible technology, applied in the field of FRP tank flexible grinding device, can solve problems such as residue, affecting fiber winding effect, and difficult to guarantee the quality of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

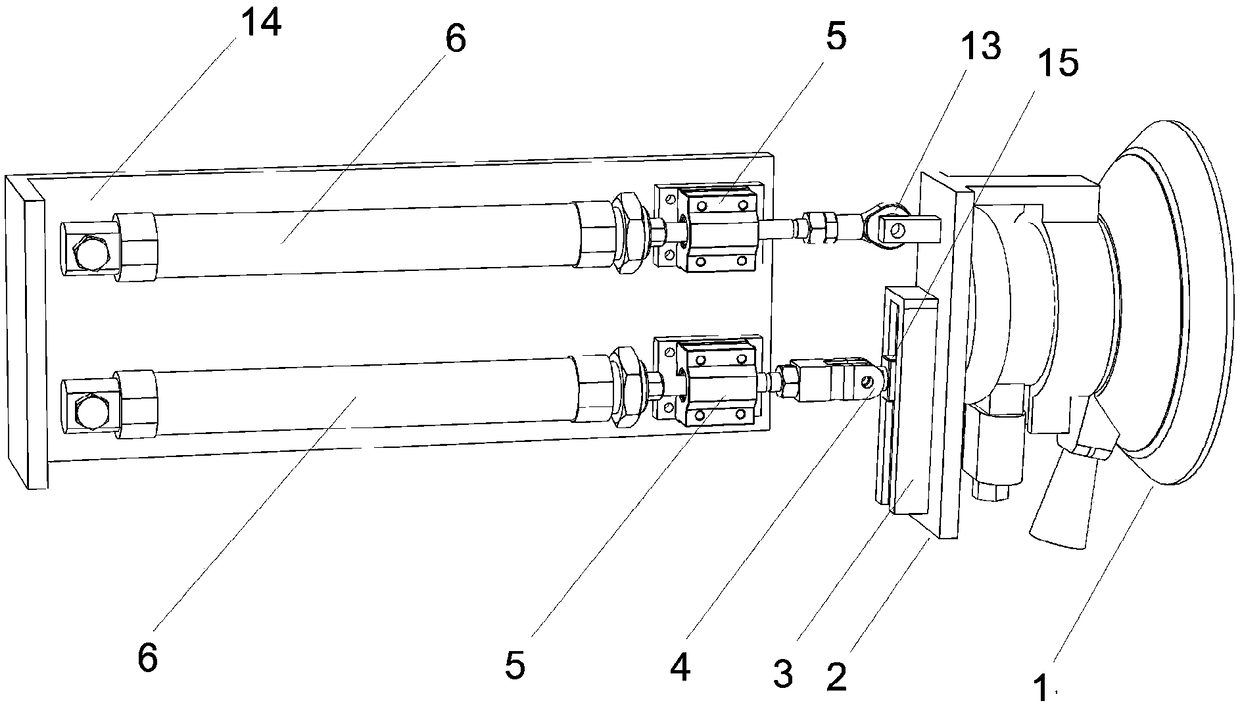

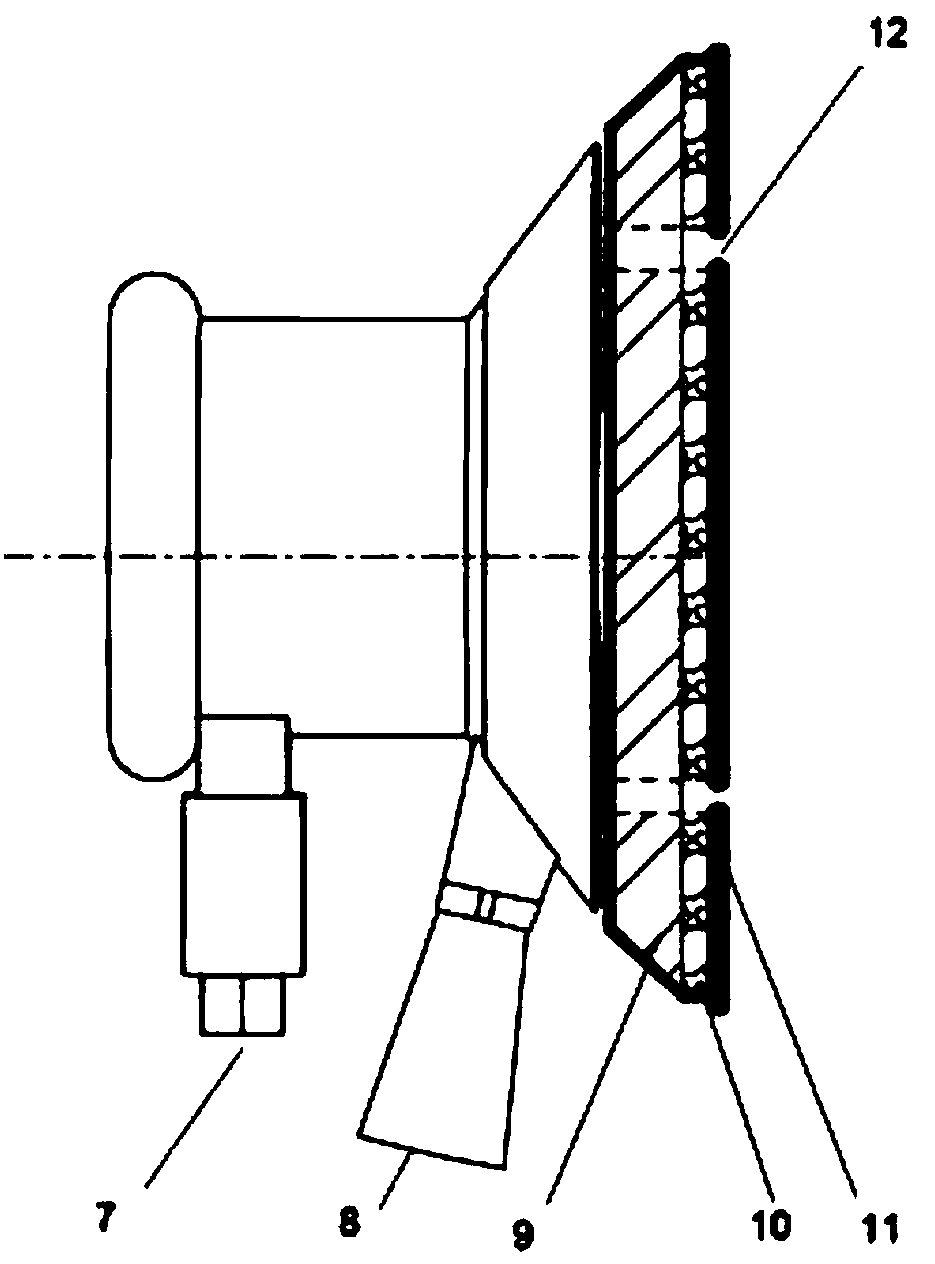

[0023] Such as figure 1 Shown, a kind of flexible polishing device of FRP tank body comprises frame 14, two horizontal cylinders 6 (in this embodiment, adopting single-rod cylinder) that are located on frame 14, support 2, located at support 2 The pneumatic grinder 1 on the side facing away from the cylinder 6, the slide rail 3 on the side facing the cylinder 6 vertically on the support 2, the slide block 15 matched with the slide rail 3, the push rod of the cylinder 6 on the upper floor and the The support 2 is hinged, the push rod of the lower cylinder 6 is hinged with the slider 15, the working surface of the pneumatic sander 1 is sandpaper 11, and there is a sponge layer 10 inside the sandpaper 11. The device uses two cylinders 6 and a pneumatic grinder 1 as the main executive components, and is light in weight, simple in structure, and low in cost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com