Marble blackboard manufacturing technology

A manufacturing process and marble plate technology, applied in the field of teaching aids, can solve problems such as discoloration, deterioration, and unfavorable students to see the blackboard clearly, and achieve the effects of preventing deterioration, long service life, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

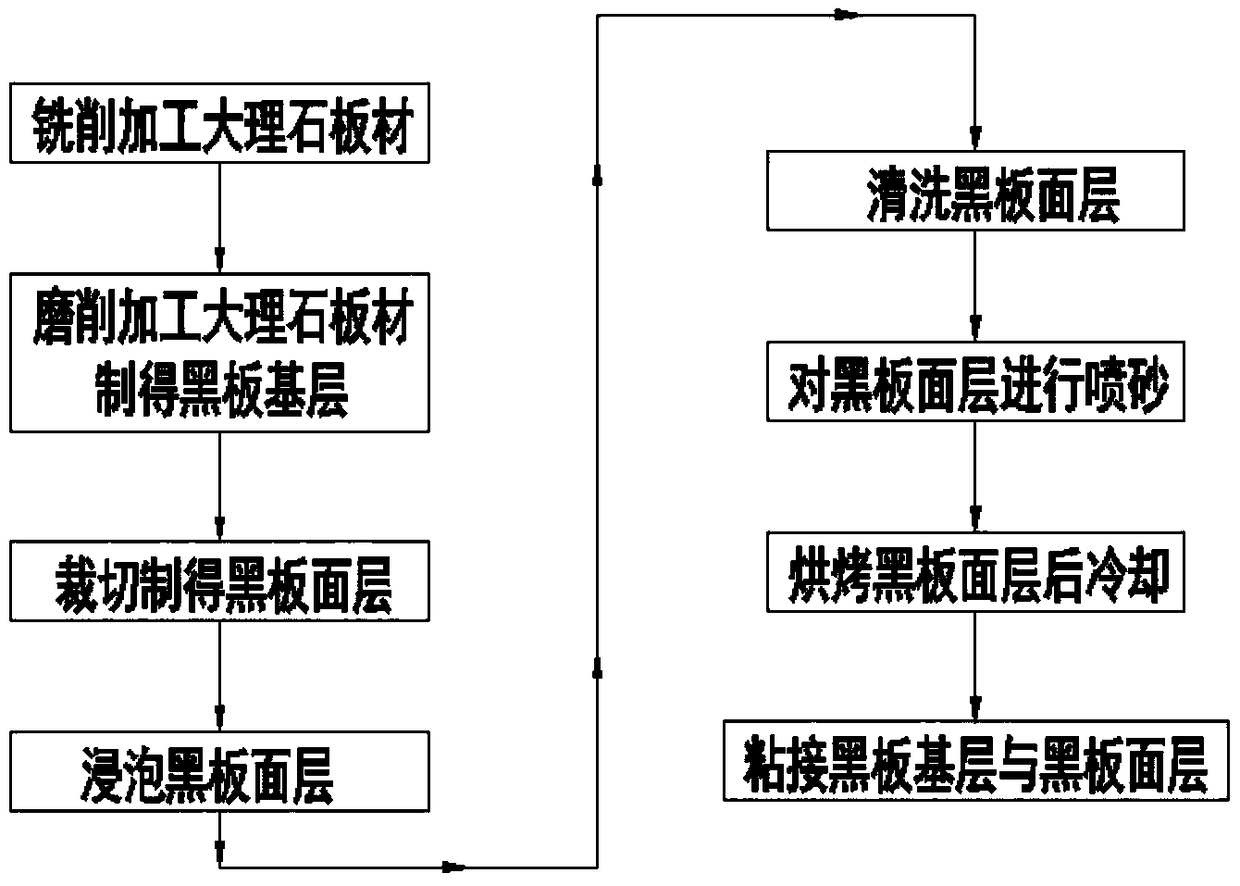

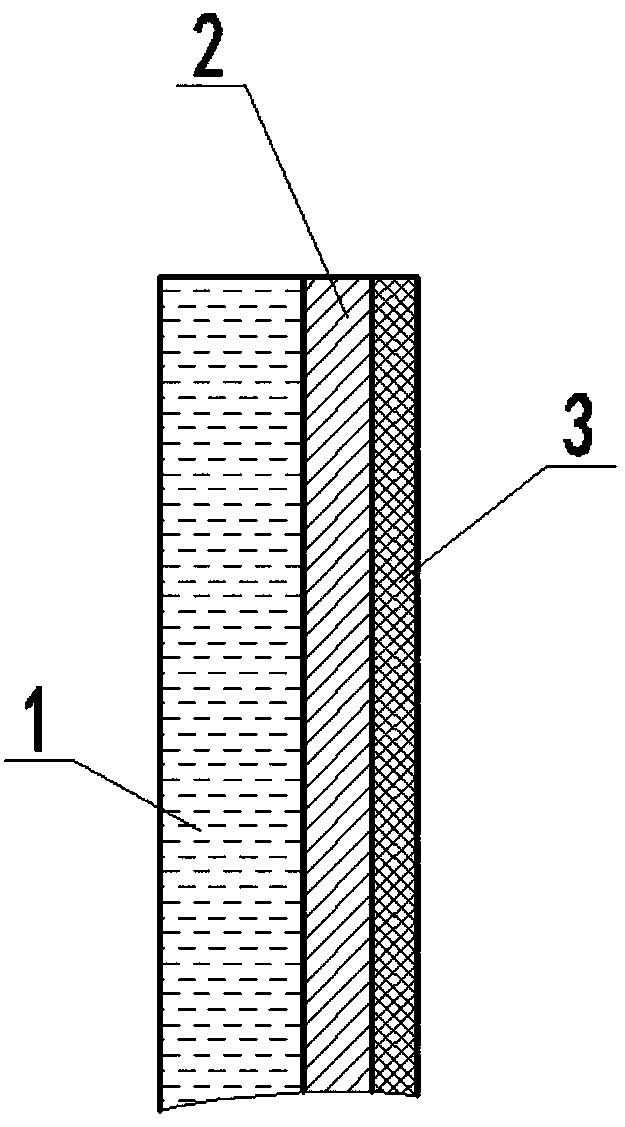

[0025] The invention provides a marble blackboard manufacturing process, such as figure 1 , figure 2 shown, including the following steps:

[0026] Step 1: Take a natural marble slab, use a milling machine to mill the marble slab, remove most of the material on the marble slab, make its surface roughness less than 25 microns, and make it have a regular cuboid shape; further, use a milling machine The process parameters for milling marble slabs are: spindle speed 800r / min~1200r / min, feed rate 60mm / min~80mm / min.

[0027] Step 2: Grinding the marble slabs with a grinding machine, so that the surface roughness of the marble slabs reaches below 12.5 microns to obtain the blackboard base 1; further, the process parameters for grinding the marble slabs with a grinding machine are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com