Solid tread rubber material, preparation and application thereof

A solid tire and surface rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as prone to frosting, poor environmental protection, complex formula and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

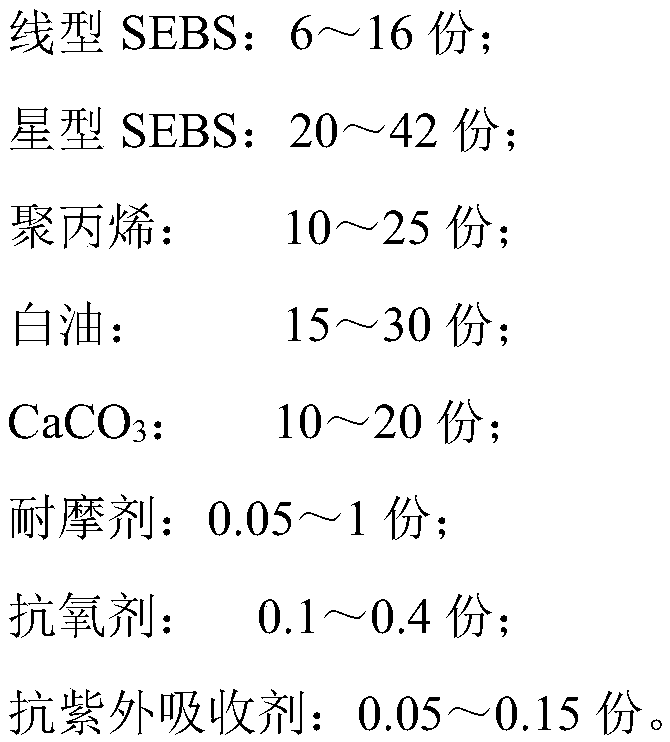

Method used

Image

Examples

Embodiment 1

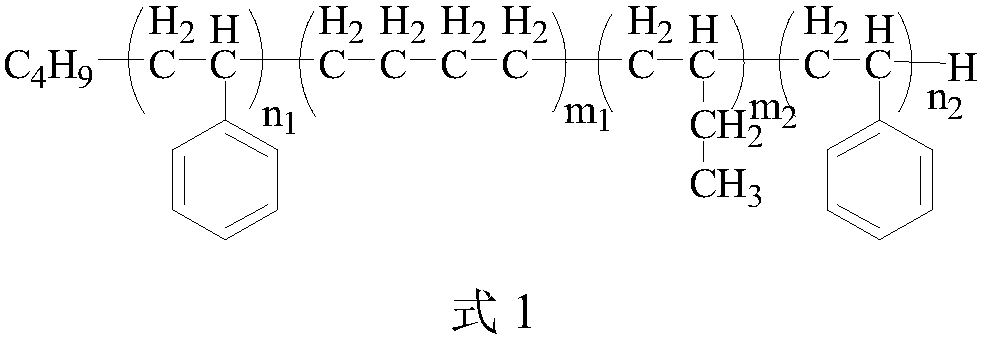

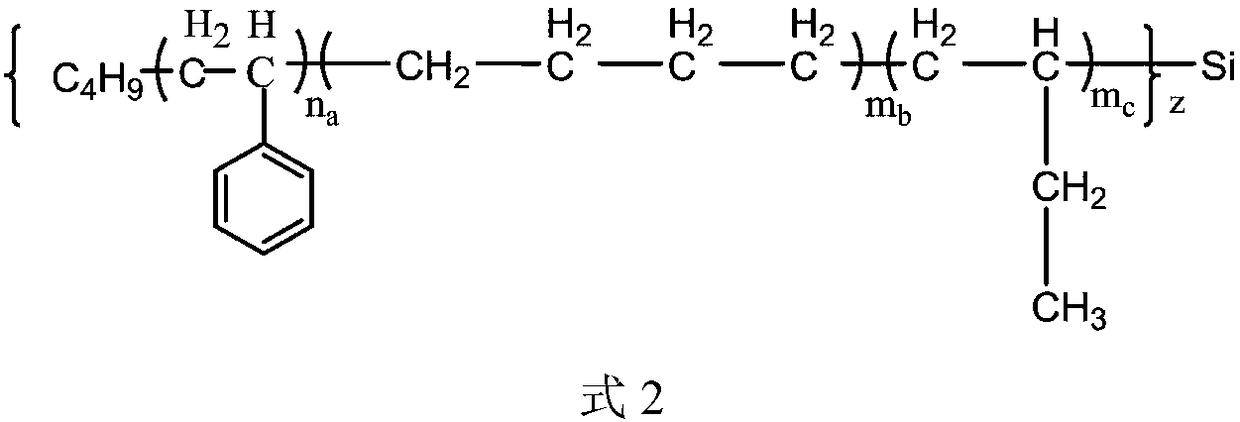

[0117] Step 1: Synthesis of SEBS

[0118] Step (1-a): Linear SEBS preparation:

[0119] Add 3000 milliliters of pure cyclohexane (water value<20ppm=1.2mL ditetrahydrofurfuryl propane (mixed with 0.5mol / L cyclohexane solution, the consumption is equivalent to 40mg / kg solvent), start stirring, raise the temperature to 60°C, then add 49mL styrene monomer and 1.5mmol n-butyl lithium respectively, polymerize for 30 minutes, then add 339mL butadiene monomer, and control the reaction by jacket water cooling The temperature is below 80°C, add 49mL styrene monomer after 40 minutes of reaction, and react for 30 minutes at a temperature of 60-65°C, and keep the pressure in the kettle at 0.1-0.5MPa during the whole polymerization process. After the polymerization reaction is completed, the glue The solution was introduced into a 10L hydrogenation tank, the temperature was raised to 70°C, 8mmol of n-butyllithium was added, and the reaction was terminated with hydrogen for 10 minutes. The...

Embodiment 2~4

[0133] Examples 2-4 Effect of linear rubber block ratio on rubber properties

[0134] Keeping other conditions unchanged, when synthesizing linear rubber, the effect of block ratio of linear rubber on the properties of rubber was investigated.

Embodiment 2

[0136] Compared with Example 1, the only difference is that in step (1-a), the block ratio (S / B mass ratio) is 25 / 35. Other conditions and components remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com