Light-diffusion polycarbonate composite material, and preparation method and application thereof

A technology of polycarbonate and composite materials, applied in the field of materials, can solve problems such as compounding and proportion optimization, lack of color rendering function, disadvantages, etc., and achieve the effect of improving color rendering index, high light transmittance, and increasing haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

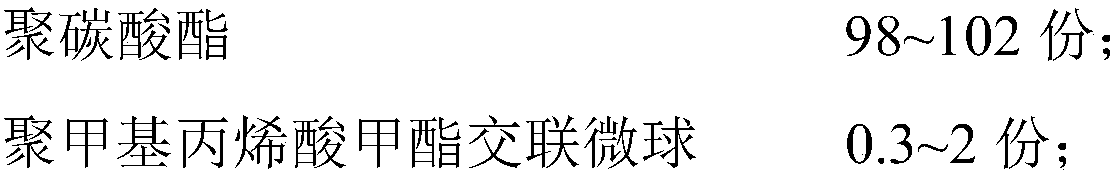

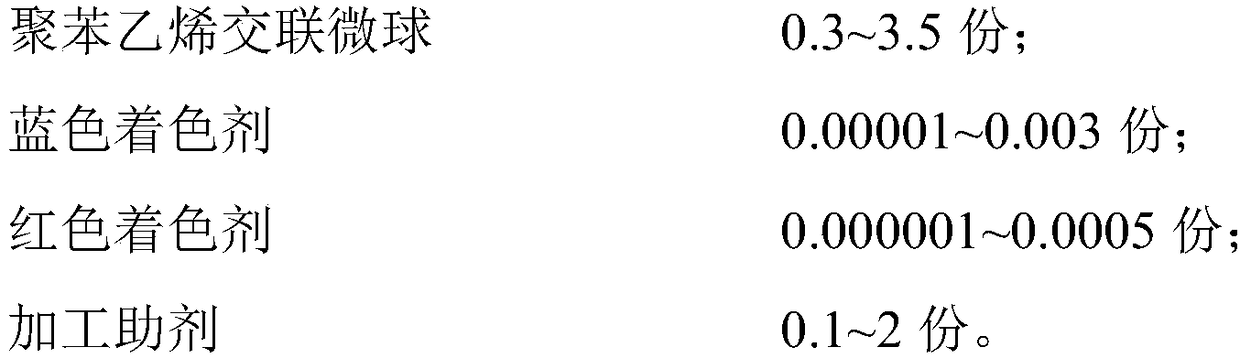

Method used

Image

Examples

Embodiment 1-2

[0085] Example 1-2, polymethyl methacrylate cross-linked microspheres and polystyrene cross-linked microspheres are used in proportion, and the appropriate amount is controlled. The light transmittance and haze of the composition are significantly improved, and the light diffusion of LED is fully achieved. At the same time, the blue color developer and the red color developer are also matched in a certain proportion, and the color rendering index R9 is obviously improved.

Embodiment 3-4

[0086] And embodiment 3-4, not only adopt blue chromogenic agent and red chromogenic agent, control their dosage, proportion, and use together, selectively absorb different wavelengths and synergize, improve the color rendering index of LED, and pass It is used in combination with polymethyl methacrylate cross-linked microspheres and polystyrene cross-linked microspheres, so that when the composition is used in LED lamps, it can also achieve high light transmittance, high haze and good performance. The best effect of the mechanical properties.

Embodiment 5-6

[0087] In Example 5-6, although the red colorant, blue colorant and light diffusing agent act synergistically, the color rendering index R9 is improved and the haze is high, but its mechanical properties and light transmittance are slightly low. The best effect can not be achieved, the reason is the defect of light diffusing agent and colorant components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com