Modular subgrade box and steel trestle platform structure and construction method thereof

A subgrade box, modular technology, applied in infrastructure engineering, underwater structures, roads and other directions, can solve the problems of inconvenient construction, narrow construction site, poor transportation roads, etc., to achieve convenient construction, reasonable overall force, Good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

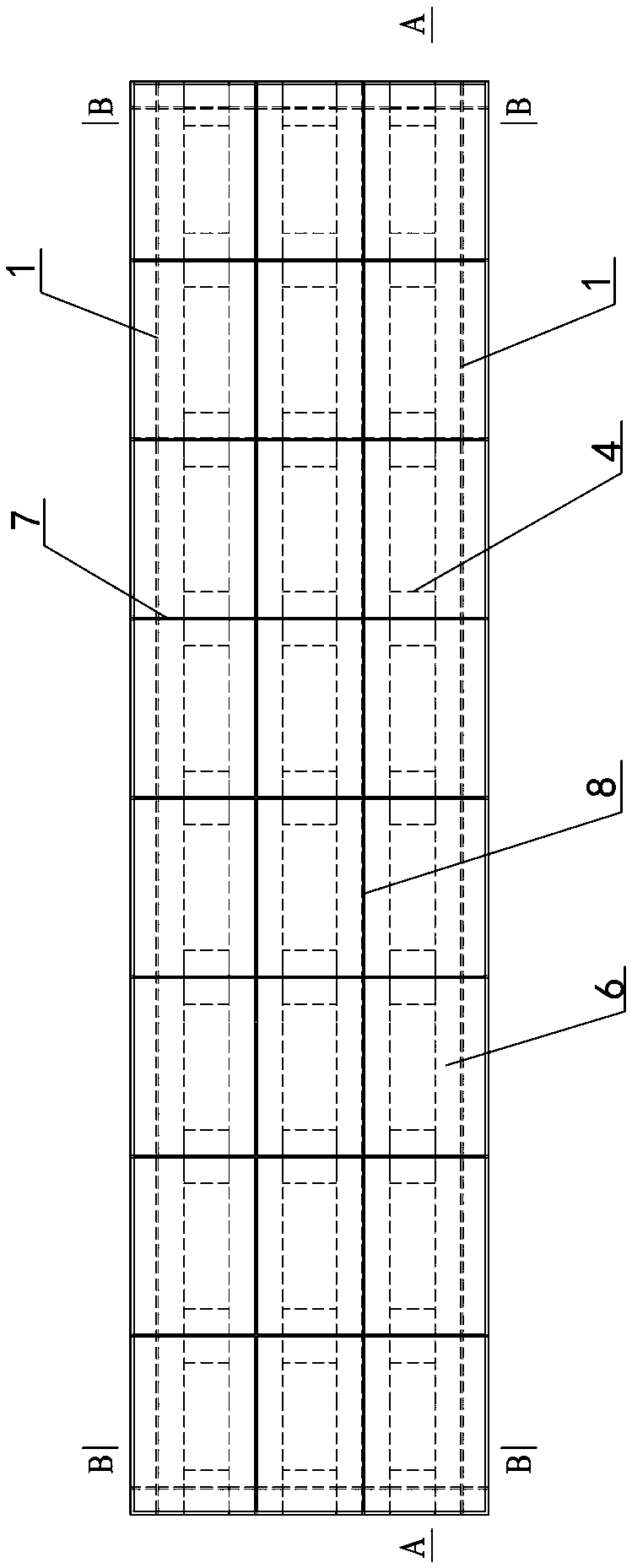

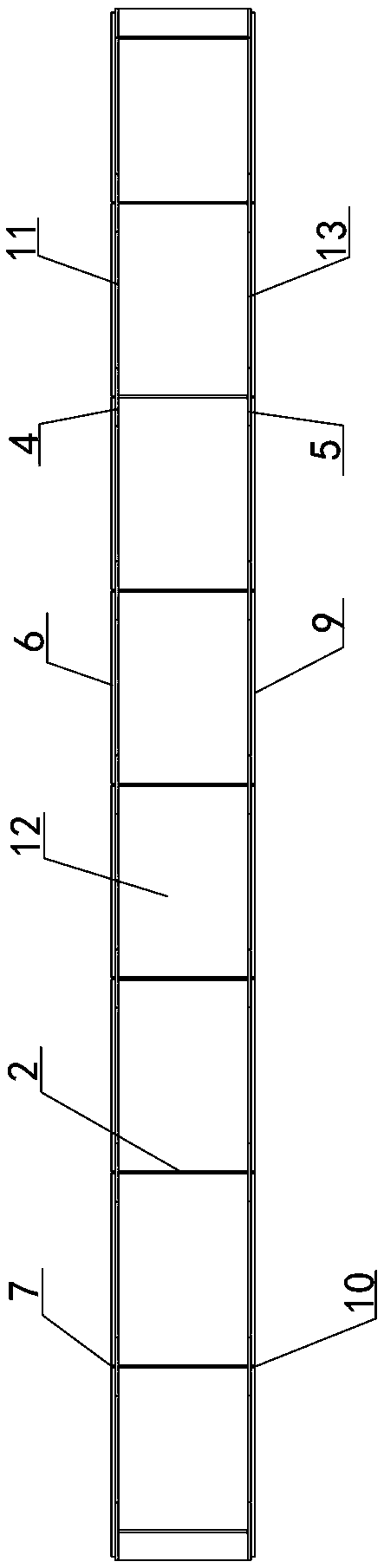

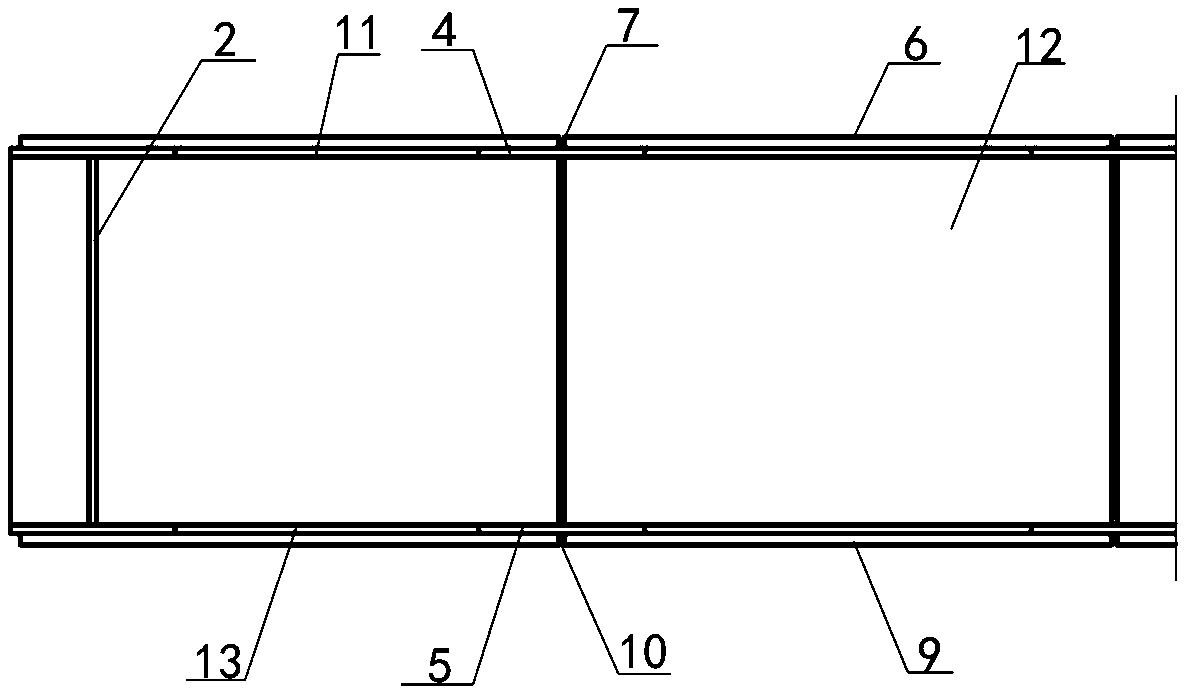

[0062] See Figure 1-5 As shown, a modular roadbed box includes four roadbed box steel beams 1, bottom plate, top plate, stiffening rib plate 2, and end sealing plate 3, which are arranged longitudinally and horizontally at parallel intervals.

[0063] The subgrade box steel girder is H-shaped steel, each road subgrade box steel girder includes an upper flange plate 11, a web 12 and a lower flange plate 13, and the subgrade box steel girder includes two side beams 1a and two middle beams 1b.

[0064] The lower side of the top plate is fully welded to the upper side of the upper flange plate 11.

[0065] The upper side of the bottom plate is fully welded to the lower side of the lower flange plate 13.

[0066] The upper connecting plate 4 is butted in the gap between the upper flange plates 11 of two adjacent road foundation box steel beams.

[0067] A lower connecting plate 5 is butted in the gap between the lower flange plates 13 of two adjacent road foundation box steel beams.

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com