Method for detecting thermal shock resistance of porous ceramic

A technology of thermal shock resistance and porous ceramics, which can be used in measuring devices, strength characteristics, instruments, etc., can solve the problems of large discrete data, large influence, and difficult to prepare, and achieve uniform numerical value, wide applicability, and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

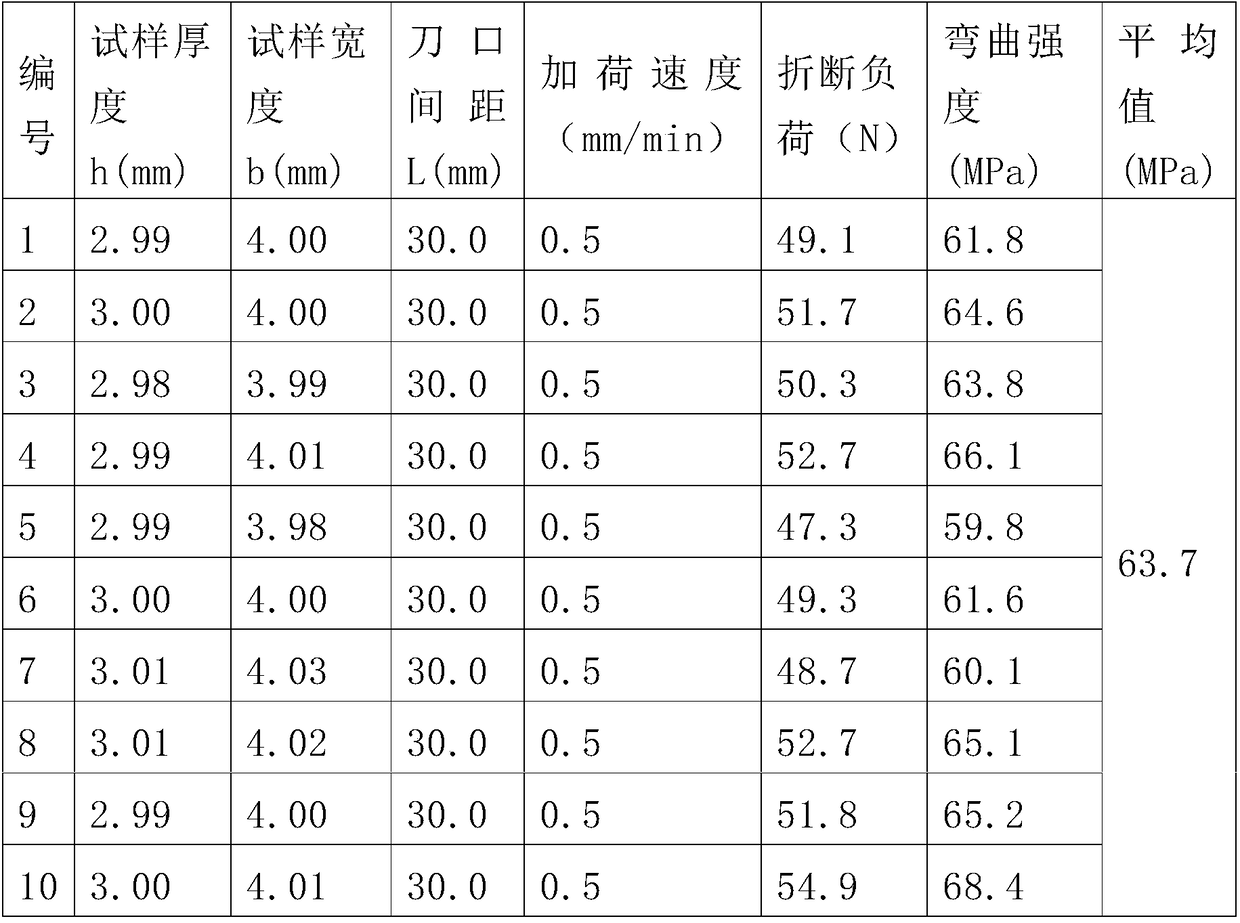

Embodiment 1

[0055] This embodiment provides a method for detecting thermal shock resistance of porous ceramics, comprising the following steps:

[0056] S1. A sample is obtained by cutting and processing the porous ceramic. The sample has a width of 8 mm, a thickness of 6 mm, a length of 70 mm, and a parallelism between the upper and lower surfaces of <0.02 mm.

[0057] The surface of the sample should be polished with 800 mesh or above sandpaper. When the particles of the sample are <0.1mm, the four longitudinal edges need to be chamfered.

[0058] Before the test, the sample needs to be passed through the organic solvent styrene or heated to 500 ° C for 3 hours to remove wax.

[0059] The sample is heated to the test temperature in the muffle furnace, the heating rate is less than 10°C / min, and then it is kept for 15-30 minutes and then quickly moved into the water bath for rapid cooling. The temperature of the water bath is 20±3°C, and the sample is cooled for 5-10s. Take it out, dry ...

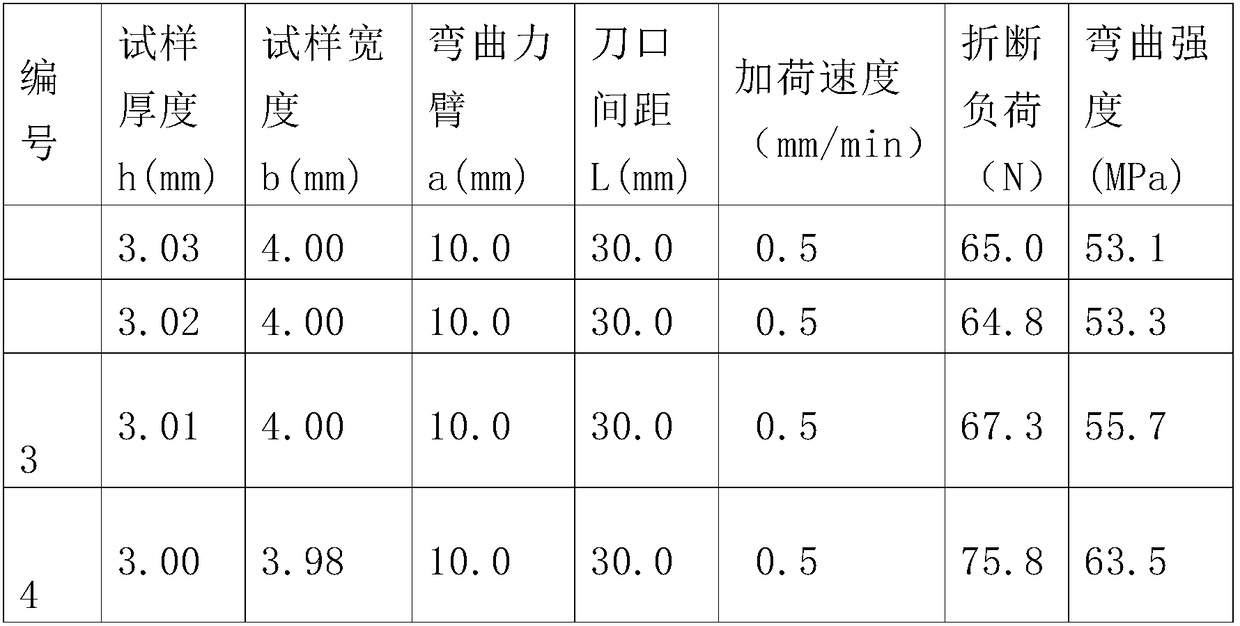

Embodiment 2

[0079] This embodiment provides a method for detecting thermal shock resistance of porous ceramics, comprising the following steps:

[0080] S1. A sample is obtained by cutting and processing the porous ceramic. The sample has a width of 8.2 mm, a thickness of 6.2 mm, a length of 75 mm, and a parallelism between the upper and lower surfaces of <0.02 mm.

[0081] The surface of the sample should be polished with 800 mesh or above sandpaper. When the particles of the sample are <0.1mm, the four longitudinal edges need to be chamfered.

[0082] Before the test, the sample needs to pass through the organic solvent perchlorethylene or heat it to 700 ° C for 1 hour to remove the wax.

[0083] The sample is heated to the test temperature in the muffle furnace, the heating rate is less than 10°C / min, and then it is kept for 15-30 minutes and then quickly moved into the water bath for rapid cooling. The temperature of the water bath is 20±3°C, and the sample is cooled for 5-10s. Take ...

Embodiment 3

[0103] This embodiment provides a method for detecting thermal shock resistance of porous ceramics, comprising the following steps:

[0104] S1. A sample is obtained by cutting and processing the porous ceramic. The sample has a width of 7.8 mm, a thickness of 5.8 mm, a length of 80 mm, and a parallelism between the upper and lower surfaces of <0.02 mm.

[0105] The surface of the sample should be polished with 800 mesh or above sandpaper. When the particles of the sample are <0.1mm, the four longitudinal edges need to be chamfered.

[0106] Before the test, the sample needs to pass through the organic solvent trichlorethylene or heat it to 600 ° C for 2 hours to remove the wax.

[0107] The sample is heated to the test temperature in the muffle furnace, the heating rate is less than 10°C / min, and then it is kept for 15-30 minutes and then quickly moved into the water bath for rapid cooling. The temperature of the water bath is 20±3°C, and the sample is cooled for 5-10s. Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com