A high power output fiber coupling device

A technology of output optical fiber and coupling device, which is applied in the application field of optical passive components, can solve the problems of troublesome adjustment, difficult disassembly and replacement of parts, and long time consumption, so as to achieve the effect of convenient operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

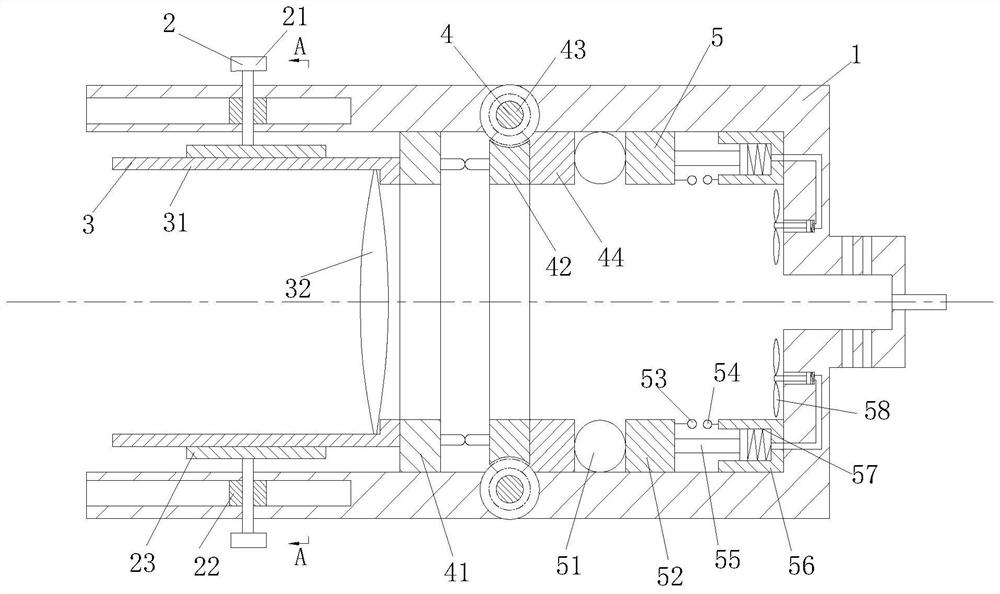

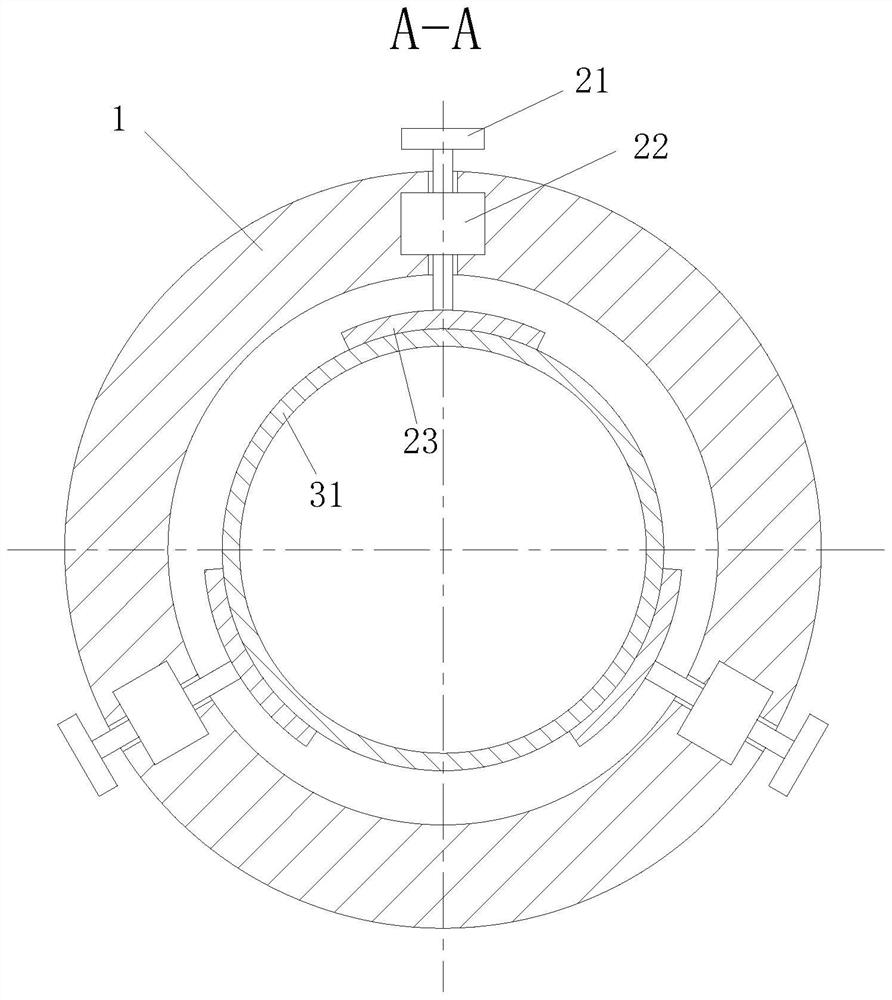

[0023] As an embodiment of the present invention, the radial adjustment mechanism 2 includes an adjustment knob 21, a slider 22 and a contact plate 23; the adjustment knob 21 is divided into two parts: a knob and a rotating shaft, and the rotating shaft is provided with threads. The adjustment knob 21 passes through the housing 1 and the slider 22, and is fixedly connected with the contact plate 23, and adjusts the position of the contact plate 23 through the adjustment knob 21, thereby adjusting the lens device 3; the slider 22 is a cuboid with a The threaded hole cooperates with the adjustment knob 21, and the slider 22 is installed in the rectangular groove on the housing 1, and can move in the rectangular groove, in order to facilitate the device to disassemble and replace parts; The plate 23 is arc-shaped, in order to increase the contact area with the lens device 3 and prevent the lens device 3 from being damaged due to excessive pressure due to the small contact area dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com