An optimization design method for channel layout of cooling water jacket of CNC machine tool spindle

A cooling water jacket and design method technology, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as hindering the improvement of water jacket performance, low design efficiency, and failure to meet design requirements, so as to improve reliability, The effect of reducing design cost and optimizing design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

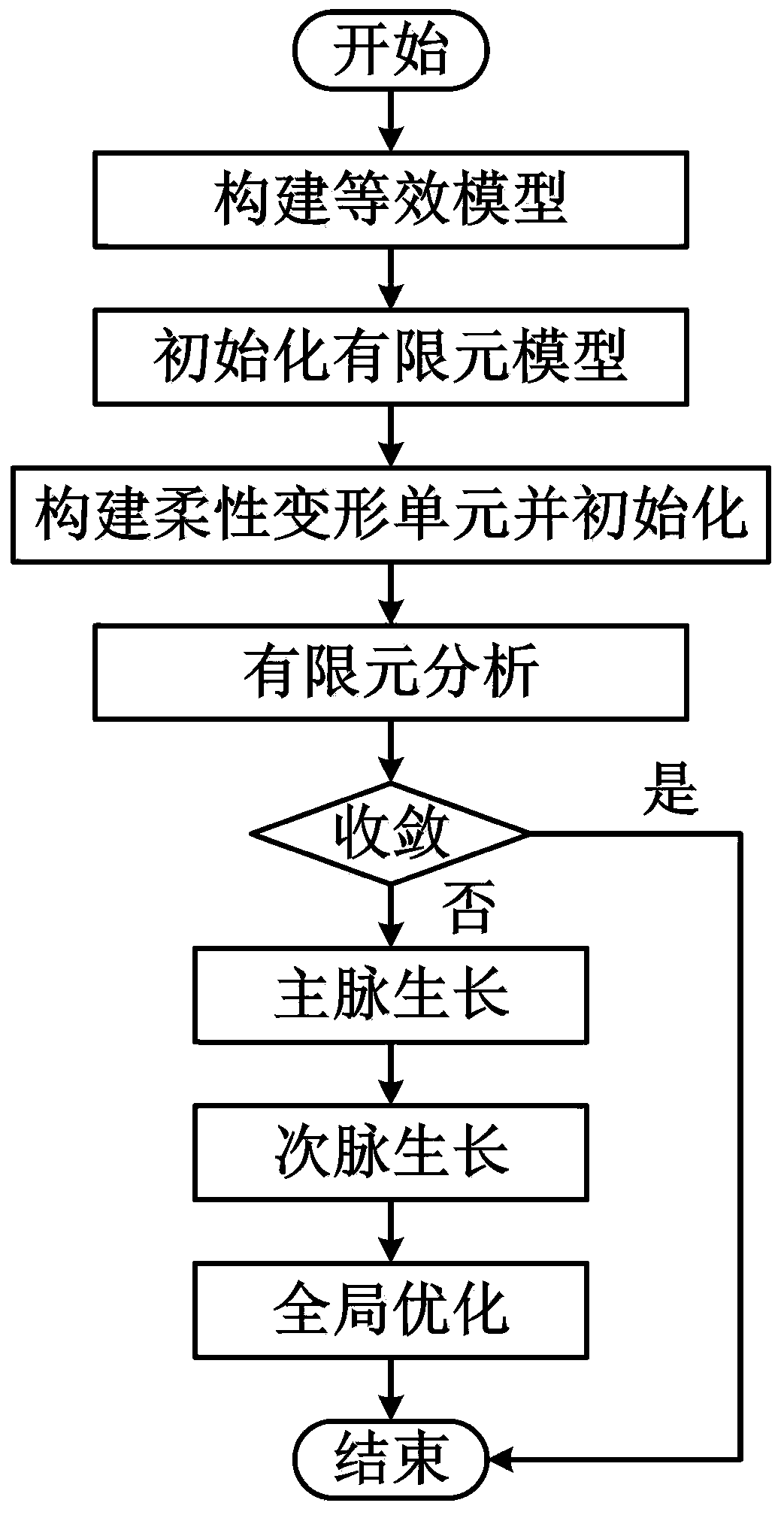

[0047] refer to figure 1 , a numerical control machine tool spindle cooling water jacket channel layout optimization design method, comprising the following steps:

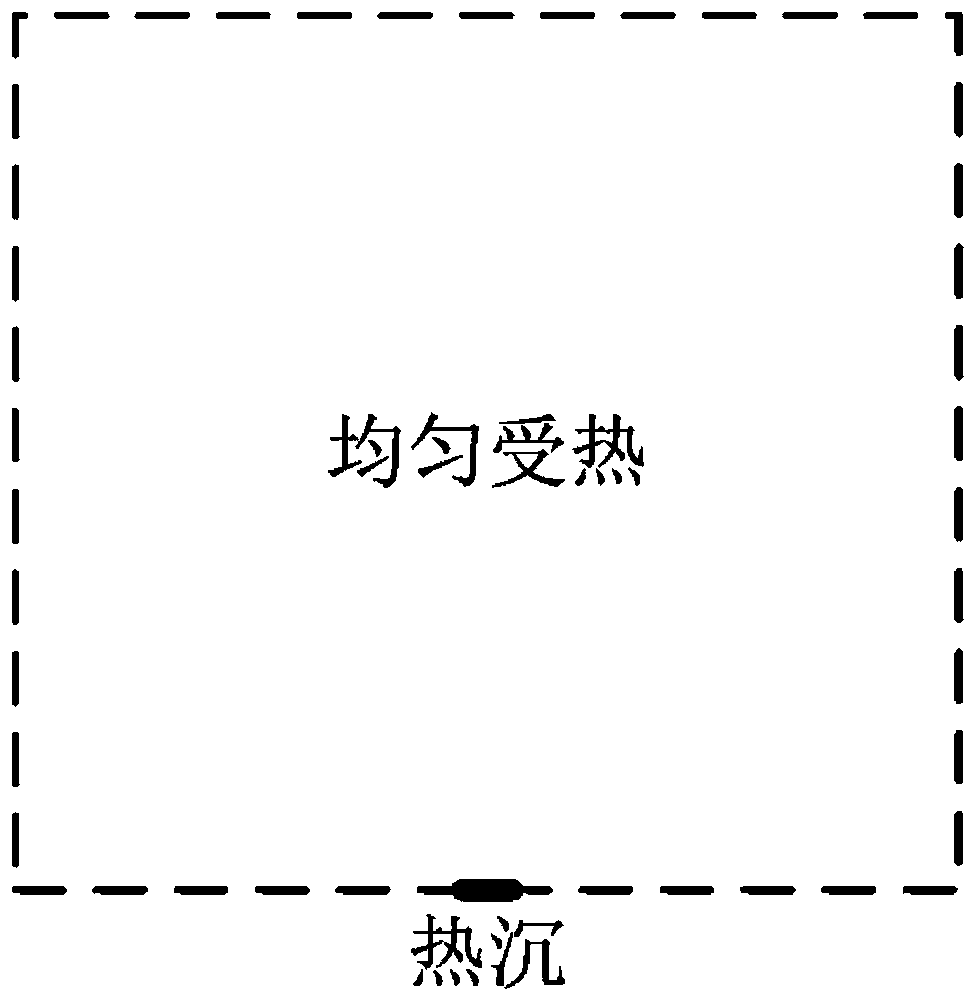

[0048] 1) Construction of equivalent model: the selected water jacket entity is equivalent to have thermal conductivity λ 0 , and use this material as the material of the low thermal conductivity substrate in the model, with high thermal conductivity λ p The water jacket channel (that is, the cooling liquid) is grown and formed on the upper part of the base material;

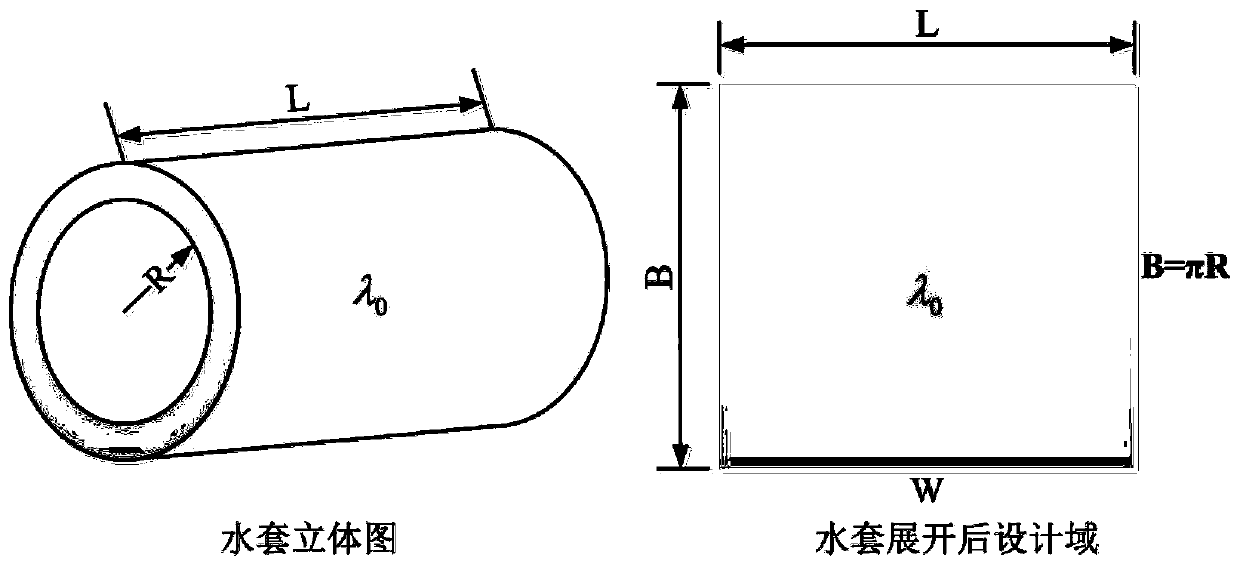

[0049] Such as figure 2 As shown, for a certain spindle, the inner diameter of the water jacket covering it is the same as the outer diameter of the spindle. Here, the water jacket covering the spindle is divided into two sections for design, that is, half of the outer circumference of the spindle is the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com