A flexible display panel and a preparation method thereof

A flexible display and panel technology, used in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of internal stress concentration, small roughness, packaging failure, etc., and achieve the effect of reducing internal stress and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The surface of the packaging film used to package OLED flexible display panels is relatively flat and has small roughness. In the flexible process that requires repeated bending, the internal stress is often unable to be released smoothly, resulting in stress concentration inside, resulting in damage to the packaging film. Damaged encapsulation films cannot block external moisture and oxygen from entering the OLED device, and black spots may be formed on the display due to encapsulation failure.

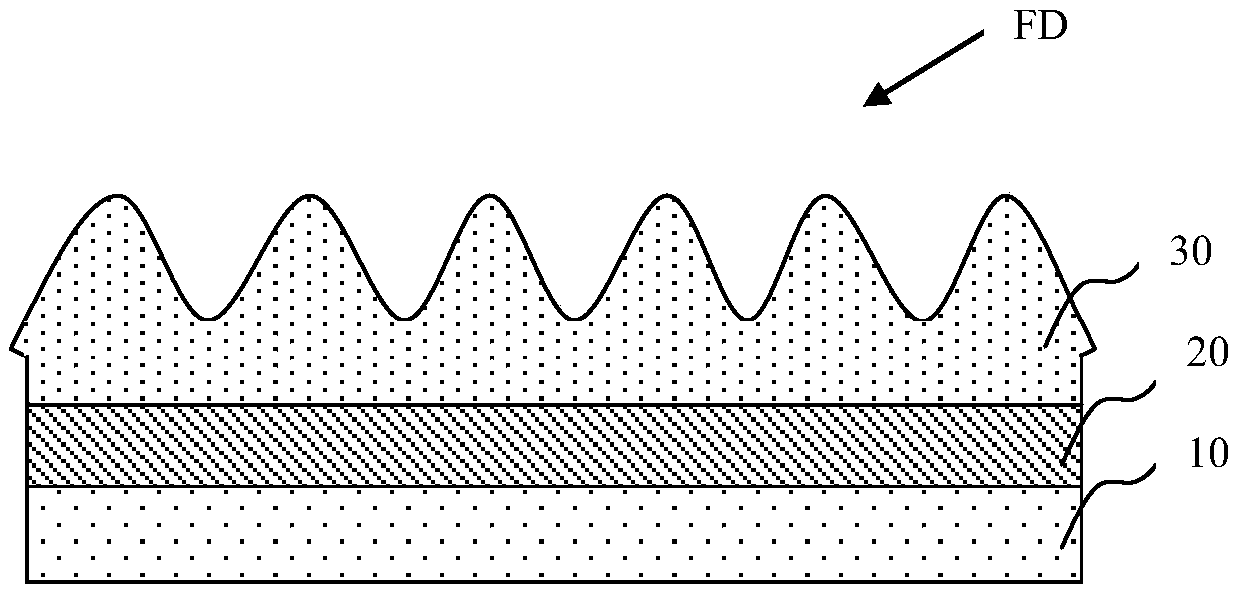

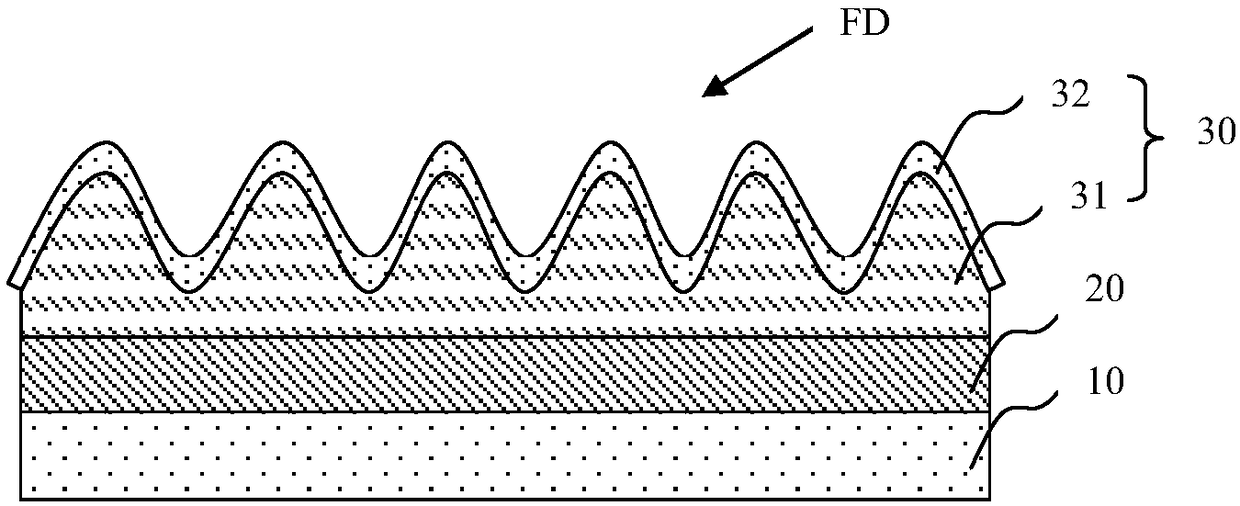

[0050] Such as figure 1 As shown, this embodiment discloses a flexible display panel, which is characterized in that it includes:

[0051] Substrate 10;

[0052] An organic light emitting diode device array 20, covering the upper surface of the substrate 10;

[0053] The packaging film 30 covers the upper surface of the organic light emitting diode device array 20, and is used to package the organic light emitting diode device array 20 on the upper surface of the substrate 1...

Embodiment 2

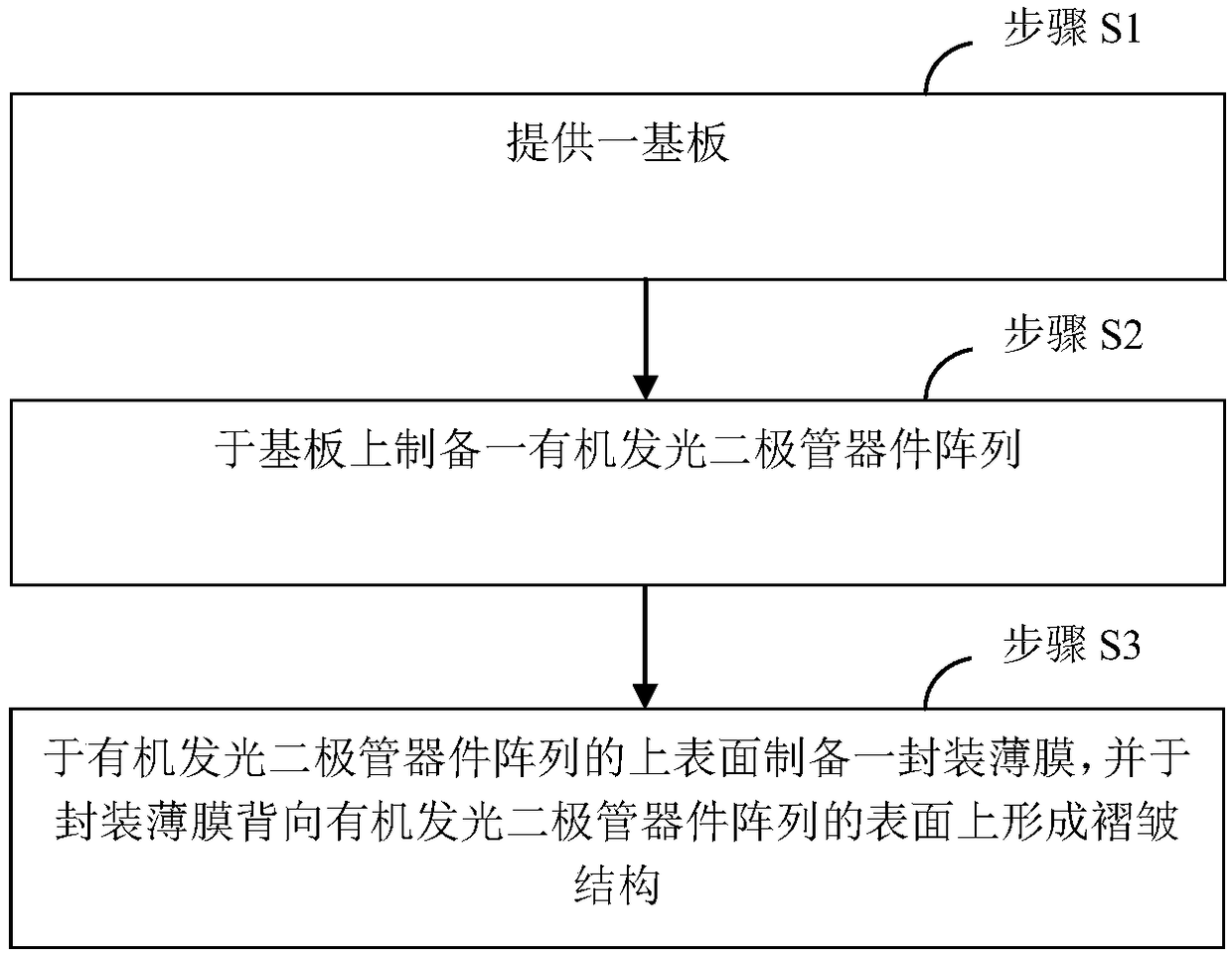

[0069] Such as image 3 As shown, it also includes a method for preparing a flexible display panel, and the formed structure can be as follows Figure 4 ~ Figure 5 As shown, can include:

[0070] Step S1, providing a substrate 10;

[0071] Step S2, preparing an organic light emitting diode device array 20 on the substrate;

[0072] Step S3 , preparing an encapsulation film 30 on the upper surface of the OLED device array 20 , and forming a wrinkle structure FD on the surface of the encapsulation film 30 facing away from the OLED device array 20 .

[0073] In the above technical solution, during the bending process of the flexible display screen, the wrinkled structure FD is formed on the surface of the packaging film 30 facing away from the organic light emitting diode device array 20, and the formed wrinkled structure FD receives little resistance, so that the packaging film 30 is formed The stress on the surface of the wrinkled structure FD can be released, so that the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com