A 3, 4, 9, 10-perylenetetracarboxylic diimide flexible organic electrode prepared based on a phase transition method

A technology of perylenetetracarboximide and organic electrodes, which is applied in active material electrodes, positive electrodes, battery electrodes, etc., can solve problems such as environmental pollution, improve mechanical strength and flexibility, improve discharge specific capacity and cycle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

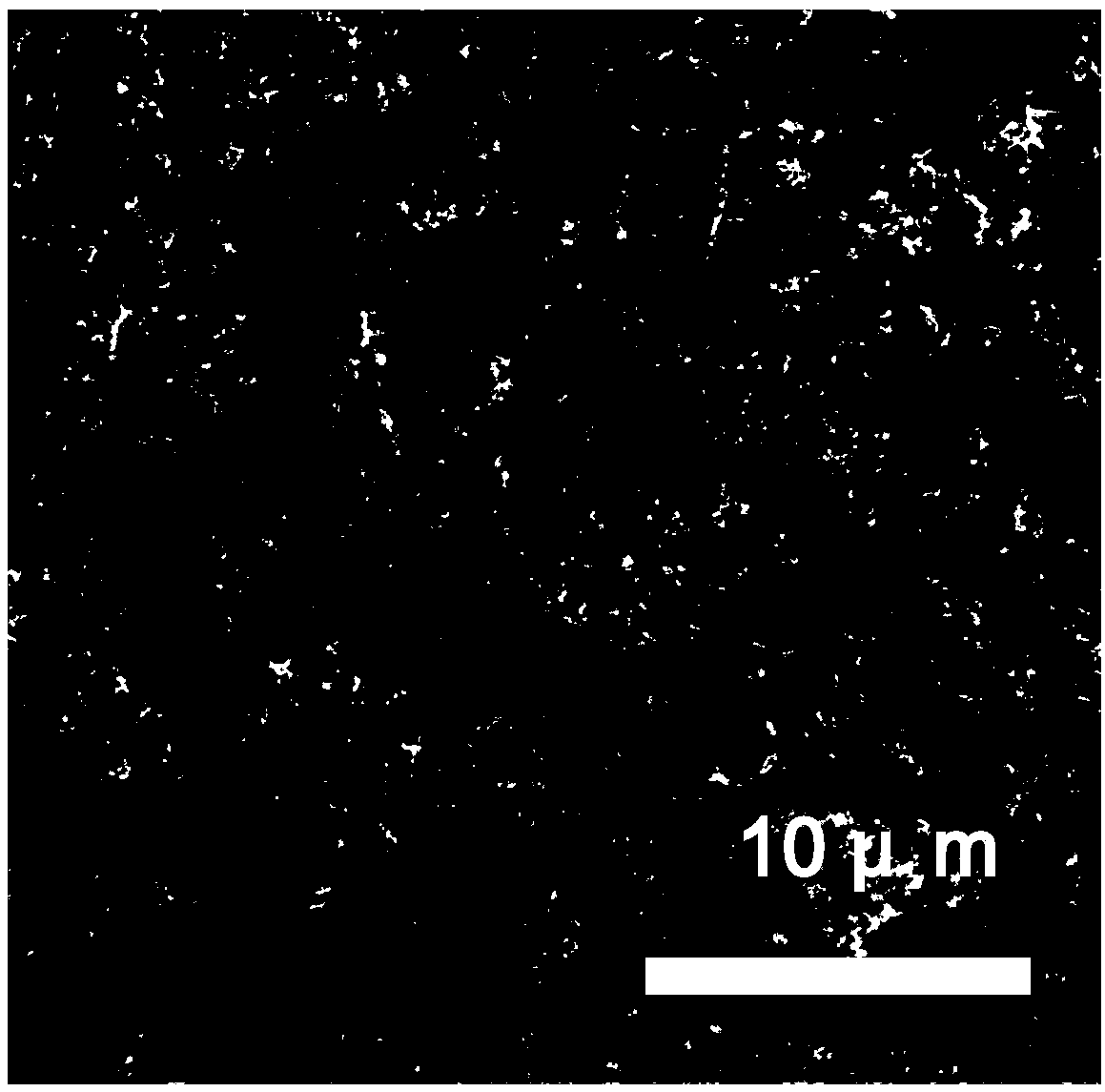

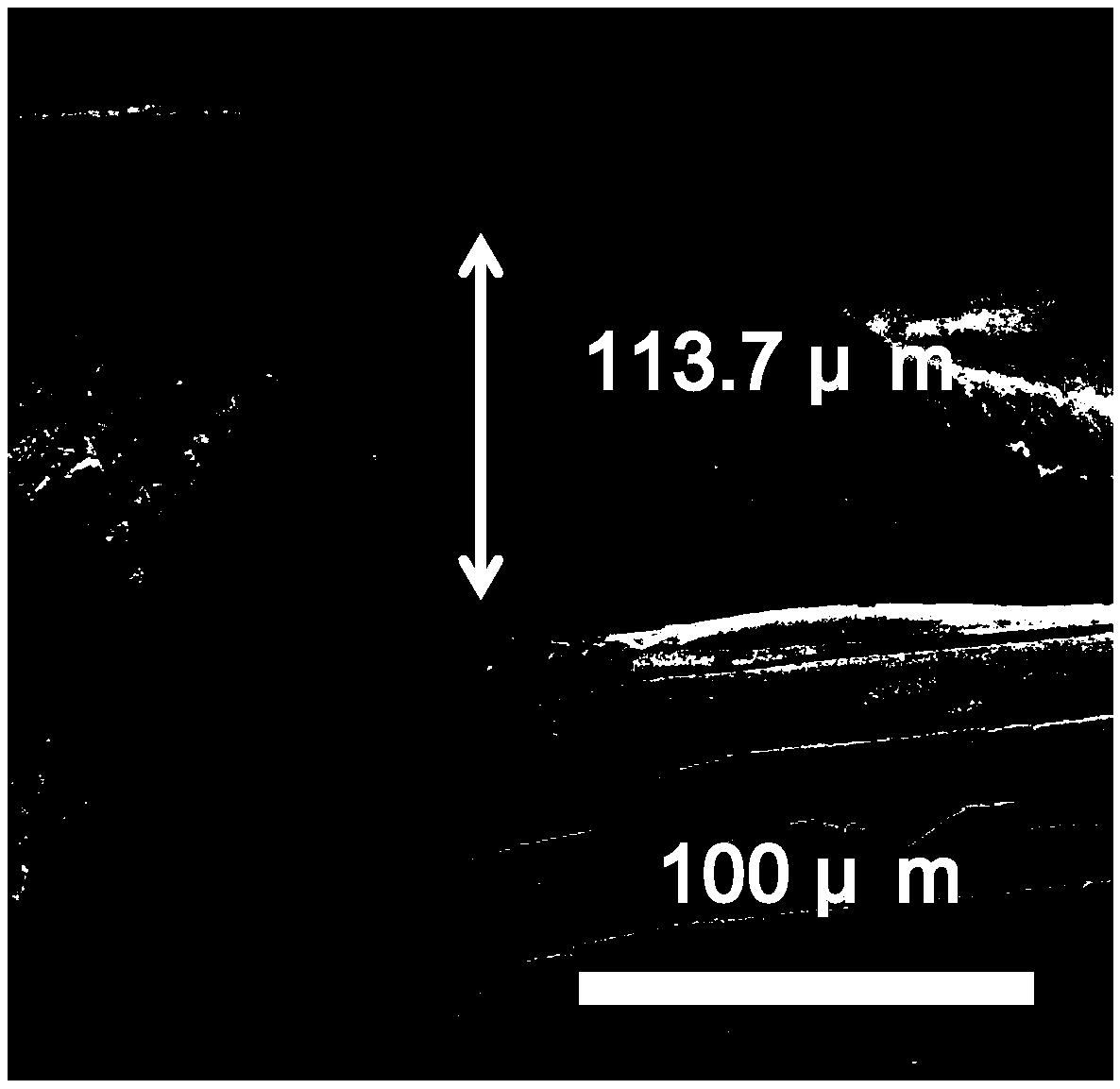

Embodiment 1

[0032] Step 1. Weigh 4.98g polyurethane (TPU) and add it to 30mL N,N-dimethylformamide (DMF), raise the temperature to 70°C, keep stirring for 2 hours, wait until the TPU is completely dissolved in the DMF solution, and cool down naturally to room temperature. Then 0.996g of 3,4,9,10-perylenetetracarboximide (PDI) and 3.984g of carbon black (CB) were added to the above solution and stirred at room temperature for 4 hours to obtain a mixed solution. The mass ratio of solution components is PDI:CB:TPU=1:4:5(wt:wt:wt).

[0033] Step 2. Apply the mixed solution obtained in step 1 evenly on the polytetrafluoroethylene template, and then immerse the polytetrafluoroethylene plate in deionized water for 4 hours to obtain a flexible organic electrode precursor.

[0034] Step 3. Transfer the flexible organic electrode precursor obtained in step 2 to a vacuum oven, and dry it in a vacuum oven at 100°C for 2 hours to obtain a flexible organic electrode that can be directly assembled into...

Embodiment 2

[0040] Step 1. Weigh 4.98g polyurethane (TPU) and add it to 30mL N,N-dimethylformamide (DMF), raise the temperature to 70°C, keep stirring for 2 hours, wait until the TPU is completely dissolved in the DMF solution, and cool down naturally to room temperature. Then 1.992g of the 3,4,9,10-perylenetetracarboximide (PDI) and 2.988g of carbon black (CB) were added to the above solution and stirred at room temperature for 4 hours to obtain a mixed solution. The mass ratio of solution components is PDI:CB:TPU=2:3:5(wt:wt:wt).

[0041] Step 2. Apply the mixed solution obtained in step 1 evenly on the polytetrafluoroethylene template, and then immerse the polytetrafluoroethylene plate in deionized water for 4 hours to obtain a flexible organic electrode precursor.

[0042] Step 3. Transfer the flexible organic electrode precursor obtained in step 2 to a vacuum oven, and dry it in a vacuum oven at 100°C for 2 hours to obtain a flexible organic electrode that can be directly assembled ...

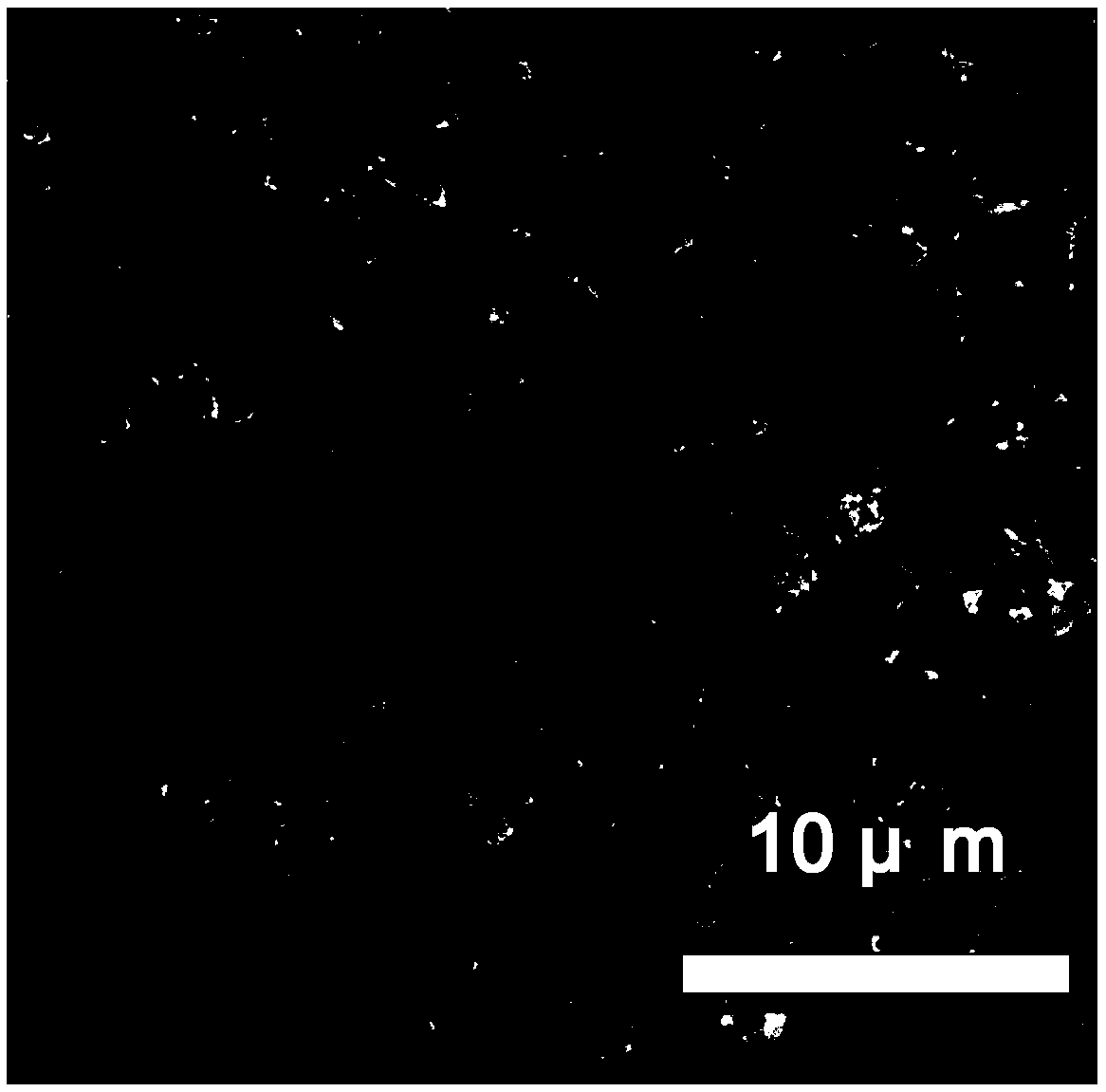

Embodiment 3

[0047] Step 1. Weigh 4.98g polyurethane (TPU) and add it to 30mL N,N-dimethylformamide (DMF), raise the temperature to 70°C, keep stirring for 2 hours, wait until the TPU is completely dissolved in the DMF solution, and cool down naturally to room temperature. Then 2.988g of 3,4,9,10-perylenetetracarboximide (PDI) and 1.992g of carbon black (CB) were added to the above solution and stirred at room temperature for 4 hours to obtain a mixed solution. The mass ratio of solution components is PDI:CB:TPU=3:2:5(wt:wt:wt).

[0048] Step 2. Apply the mixed solution obtained in step 1 evenly on the polytetrafluoroethylene template, and then immerse the polytetrafluoroethylene plate in deionized water for 4 hours to obtain a flexible organic electrode precursor.

[0049] Step 3. Transfer the flexible organic electrode precursor obtained in step 2 to a vacuum oven, and dry it in a vacuum oven at 100°C for 2 hours to obtain a flexible organic electrode that can be directly assembled into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com