Liquid culture medium for industrialized production of flammulina velutipes and application of liquid culture medium

A liquid culture medium, industrialized technology, applied in the fields of application, mushroom cultivation, cultivation, etc., can solve the problems of poor cultivation effect, low nutrient utilization rate, long solid medium cycle, etc., and achieve low price and good mycelium Absorbs and guarantees the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

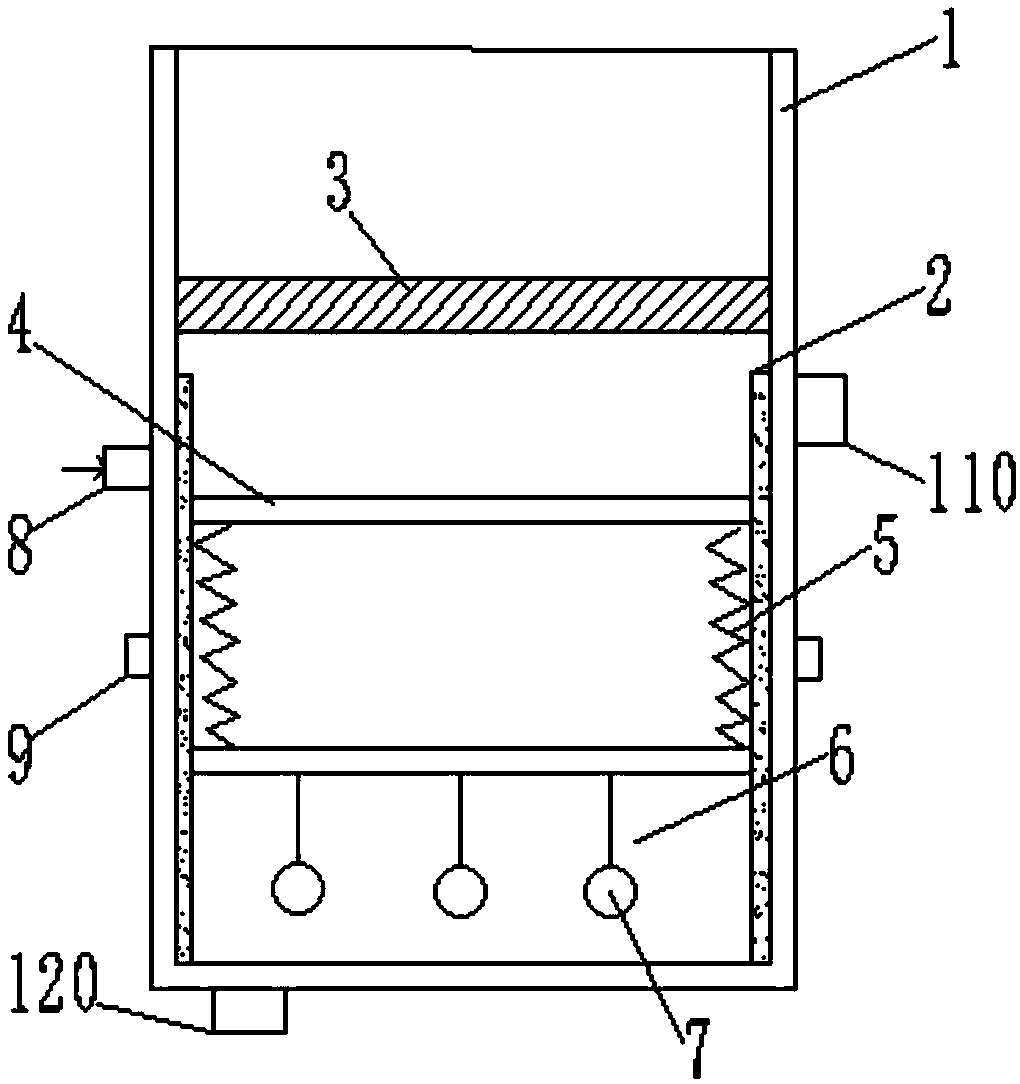

Image

Examples

Embodiment 1

[0035] A liquid culture medium for factory production of Flammulina velutipes, comprising the following components measured in parts by weight:

[0036] 7 parts soybean meal, 6 parts yeast powder and 90 parts sugar;

Embodiment 2

[0038] A liquid culture medium for factory production of Flammulina velutipes, comprising the following components measured in parts by weight:

[0039] 7 parts of soybean meal, 6 parts of yeast powder and 90 parts of sugar; 40 parts of deep well water, 30 parts of buckwheat flour, 3 parts of fish meal, 3 parts of peptone, 1.0 part of distiller's yeast, 0.7 part of potassium bicarbonate, 0.7 part of calcium chloride, 0.5 part of nitric acid Potassium and 0.3 parts of magnesium sulfate.

Embodiment 3

[0041] A liquid culture medium for factory production of Flammulina velutipes, comprising the following components measured in parts by weight:

[0042] 7 parts of soybean meal, 6 parts of yeast powder and 90 parts of sugar; 40 parts of deep well water, 30 parts of buckwheat flour, 3 parts of fish meal, 3 parts of peptone, 1.0 part of distiller's yeast, 0.7 part of potassium bicarbonate, 0.7 part of calcium chloride, 0.5 part of nitric acid Potassium and 0.3 parts of magnesium sulfate.

[0043] A kind of preparation technology of liquid medium for factory production of Flammulina velutipes comprises the following steps:

[0044] 1) Soak the above weight portion of soybean meal, drain, steam, and mix well with the above weight portion of yeast powder and sugar; put it in a sealed tank, and place the sealed tank in a warm water bath at 35-40°C for 48 hours, Obtain fermented soybean meal; wherein, during the water bath process, shake the sealed tank every 8 hours to shake the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com