Rapid processing method of chiffon cakes

A technology of chiffon cake and processing method, which is applied in the direction of baking method, dough processing, baking, etc., can solve the problems of slow heating, uneven heating, internal overcooking, etc., and achieve strong operability, reasonable production process, Energy and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

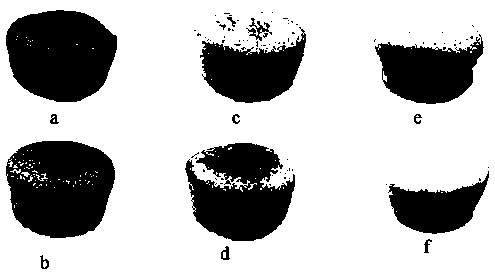

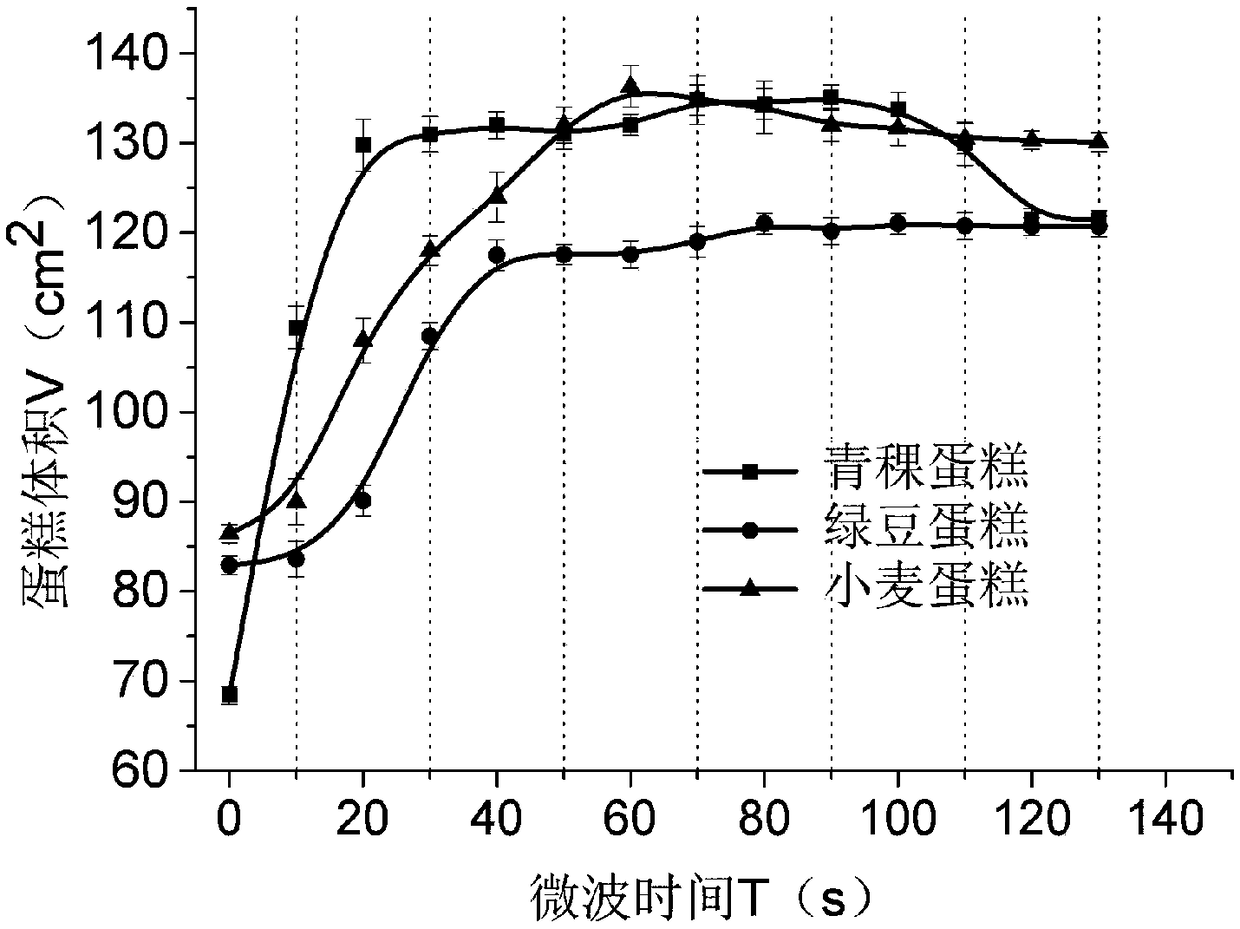

Embodiment 1

[0042] (1) Mix 60g of highland barley flour (80 mesh), 40g of wheat flour, 2.5g of baking powder, and 1g of salt.

[0043] (2) Add 75g of egg yolk, 150g of milk, and 40g of corn oil in turn and stir well to form a sticky paste for later use.

[0044] (3) Add 2.5g of cream of tartar to 158g of egg white, take 66g of white granulated sugar and add in three times, and beat until completely non-flowing.

[0045] (4) Add 2 / 5 of the egg whites that have been whipped in step (3) to the batter that has been well mixed in step (2) and stir it into a homogenous slurry, then add the remaining 3 / 5 of the beaten egg whites and mix moderately, then Put the cake batter evenly into the molds, control the net weight of the cake batter added to each mold at 30-33g, and the cake surface area at 43-46cm 2 .

[0046] (5) The mold with the cake batter in step (4) is first microwaved for 21 seconds, and the microwave load condition is 6.5×10 3 J / (kg s), and then bake it with hot air. The curing c...

Embodiment 2

[0050] (1) Mix 80g mung bean cooked flour (100 mesh), 20g wheat flour, 3.3g baking powder and 1g salt well.

[0051] (2) Add 65g of egg yolk, 140g of milk, and 50g of peanut oil in turn and stir well to form a sticky paste for later use.

[0052] (3) Add 3.0g of cream of tartar to 148g of egg white, take 50g of white sugar and add in three times, and beat until completely non-flowing.

[0053] (4) Add 1 / 2 of the egg whites that have been beaten in step (3) to the batter that has been well-mixed in step (2) and stir it into a homogenous slurry, then add the remaining 1 / 2 of the beaten egg whites for moderate mixing, then Put the cake batter evenly into the mold, control the net weight of the cake batter added to each mold at 32-34g, and the cake surface area at 47-50cm 2 .

[0054] (5) The mold with the cake batter in step (4) is first microwaved for 40 seconds, and the microwave loading condition is 6.9×10 3 J / (kg s), and then bake it with hot air. The curing conditions are...

Embodiment 3

[0058] (1) Mix 100g wheat flour (100 mesh), 4.0g baking powder and 2g salt well.

[0059] (2) Add 70g of egg yolk, 100g of milk, and 35g of rapeseed oil in turn and stir well to form a sticky paste for later use.

[0060] (3) Add 3.0g of cream of tartar to 153g of egg white, take 60g of white granulated sugar and add in three times, and beat until completely non-flowing.

[0061] (4) Add 1 / 3 of the egg whites that have been whipped in step (3) to the batter that has been well mixed in step (2) and stir it into a homogenous slurry, then add the remaining 2 / 3 of the beaten egg whites and mix moderately, then Put the cake batter evenly into the mold, control the net weight of the cake batter added to each mold at 33-35g, and the cake surface area at 42-45cm 2 .

[0062] (5) The mold with the cake batter in step (4) is first microwaved for 60 seconds, and the microwave loading condition is 7.2×10 3 J / (kg·s), and then bake it with hot air. The curing conditions are set as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com