Automatic extruding and material dropping device for blasting beads

An automatic extrusion and dripping technology, which is applied in the field of food processing, can solve the problems of dripping on the formed popping beads, mutual adhesion, and low yield of popping beads, so as to facilitate collection, reduce the influence of mutual contact, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

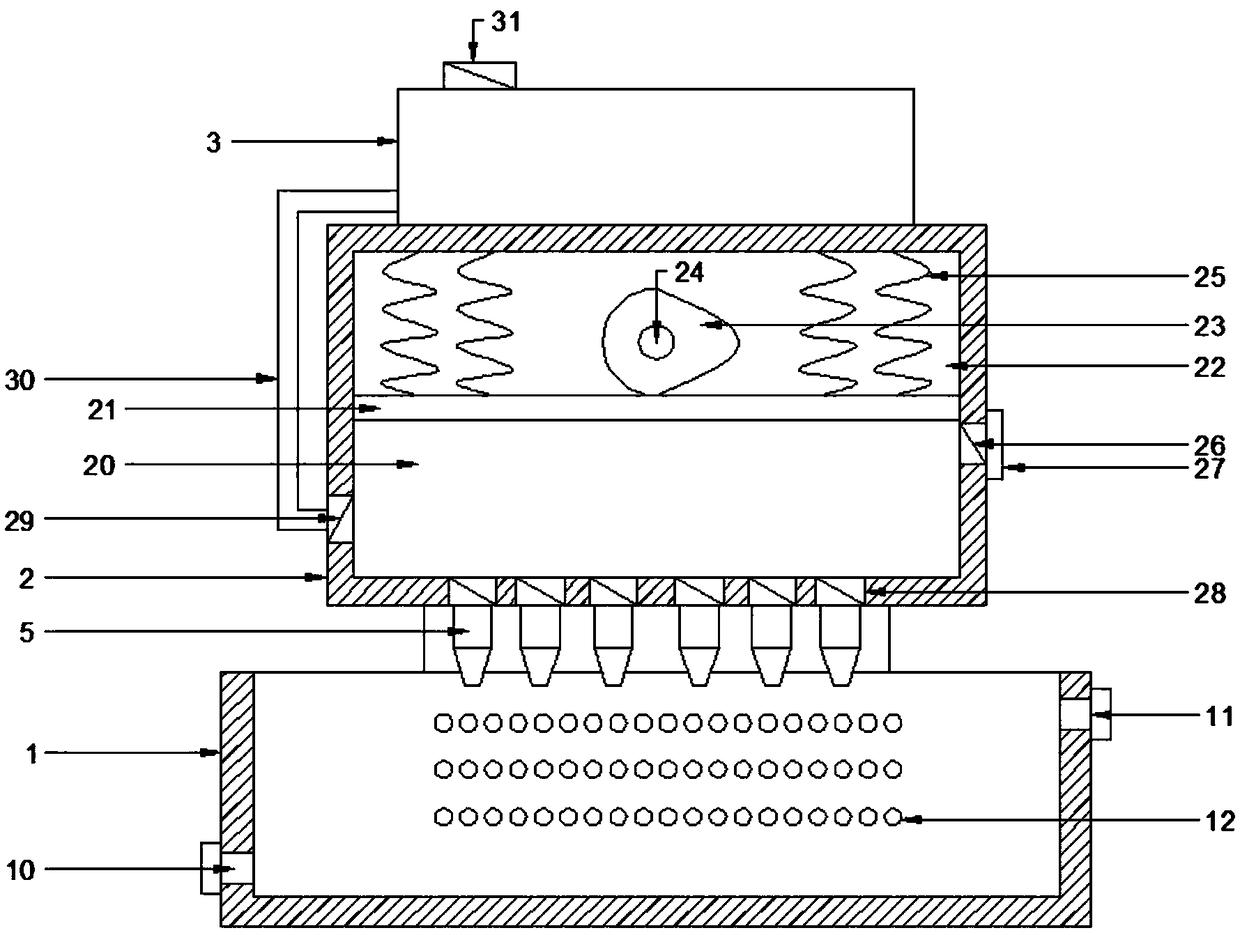

[0020] see Figure 1~3 , in the embodiment of the present invention, a kind of popping bead automatic extrusion dripping device comprises forming pool 1, automatic extrusion box 2, material storage box 3, motor box 4, dripping head 5, the back of described forming pool 1 The motor box 4 is fixed on the panel, the top of the motor box 4 is fixed with the storage box 3, the front panel of the motor box 4 is fixed with the automatic extrusion box 2, and the bottom of the automatic extrusion box 2 passes through multiple A drop material check valve 28 with an opening outward is connected to the drop material head 5, and the inside of the automatic squeeze box 2 is slidingly clamped with a piston plate 21, and the piston plate 21 moves the inside of the automatic squeeze box 2 from top to bottom. The bottom is divided into a raw material chamber 20 and an extrusion chamber 22. The front and rear inner walls of the extrusion chamber 22 are fixed with rotation 24. The rear end of the...

Embodiment 2

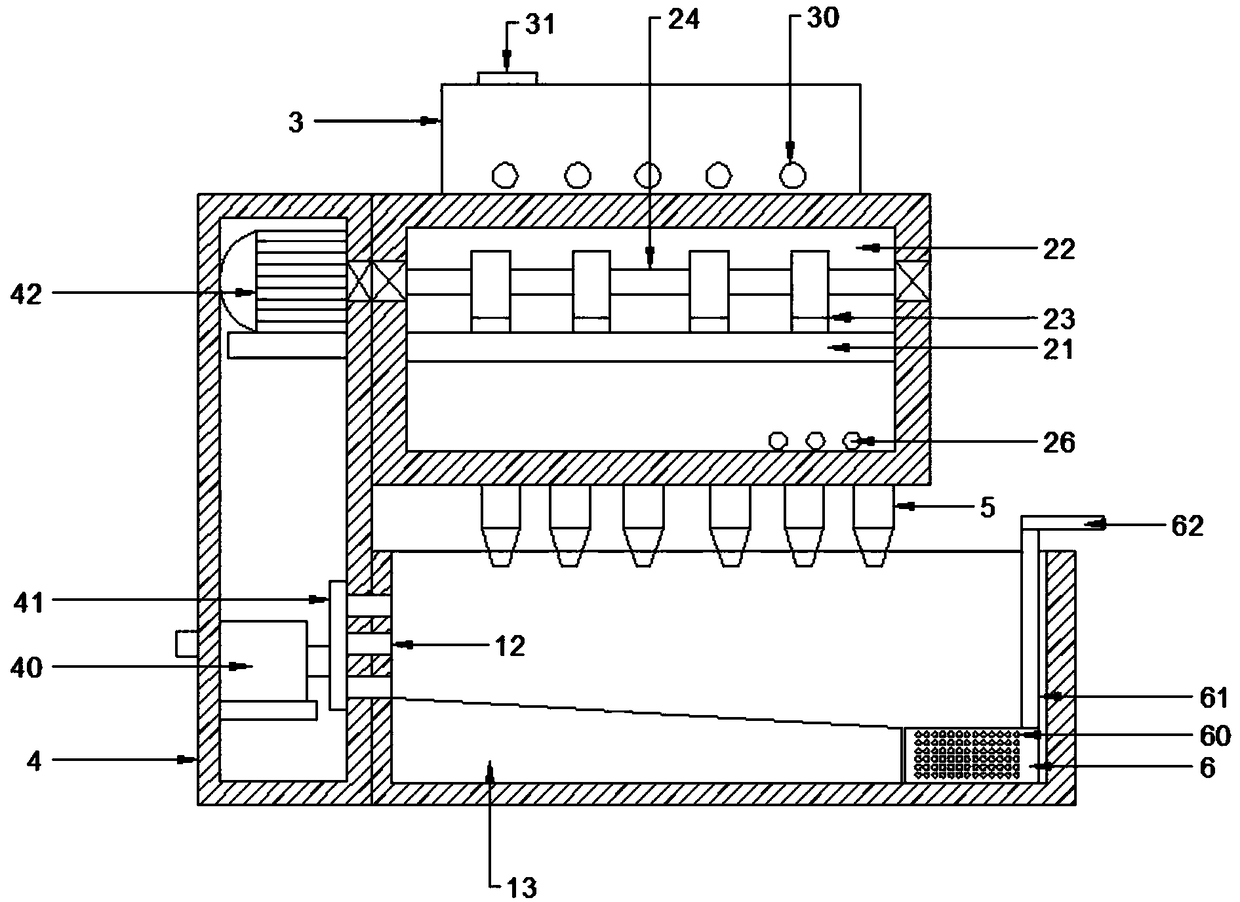

[0029] The present invention differs from Embodiment 1 in that:

[0030] The forming tank 1 is provided with a collection device for collecting popping beads, the rear panel of the forming tank 1 is provided with an air blowing device that drives the solution inside the forming tank 1 to roll, and the bottom of the left side wall of the forming tank 1 is provided with a liquid discharge device. Port 10, the top position of the right side wall of said 1 is provided with a liquid inlet 11;

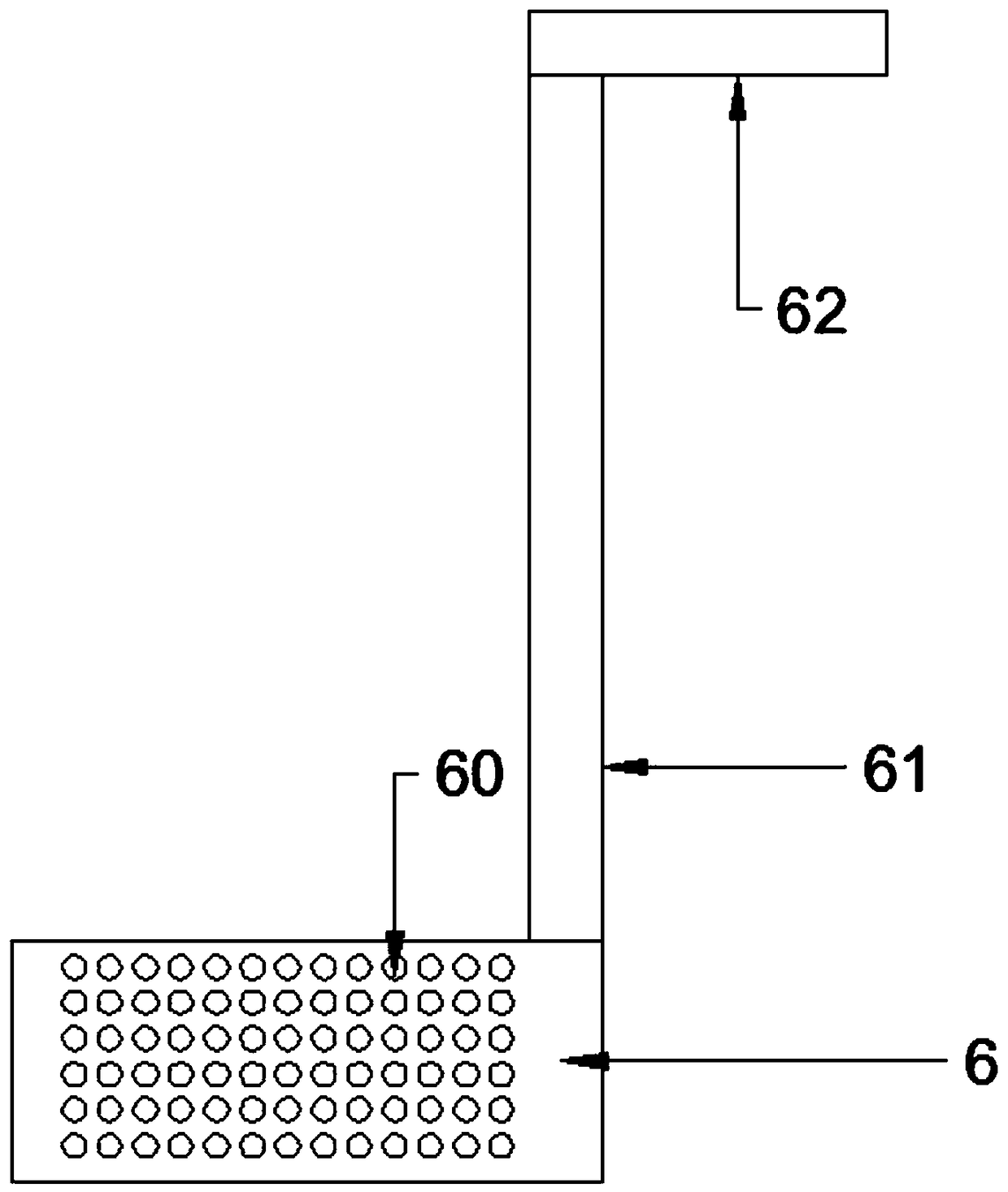

[0031] The collecting device includes a deflector 13 and a material receiving tube 6, the deflector 13 is obliquely arranged at the inner bottom of the forming tank 1, the front edge of the deflector 13 is placed on the receiving tube 6, and the receiving tube 6 is placed on the front edge of the deflector 13. The top opening of the material receiving cylinder 6 is parallel to the bottom of the inclined plane of the deflector 13, and a plurality of liquid leakage holes 60 are provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com