Ship exhaust gas filtering and waste heat recovery and utilization device and using method thereof

A waste heat recovery and waste gas filtration technology, which is applied in chemical instruments and methods, combined devices, ship propulsion, etc., can solve problems such as poor purification effect, inadequate waste gas purification treatment, and waste gas emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

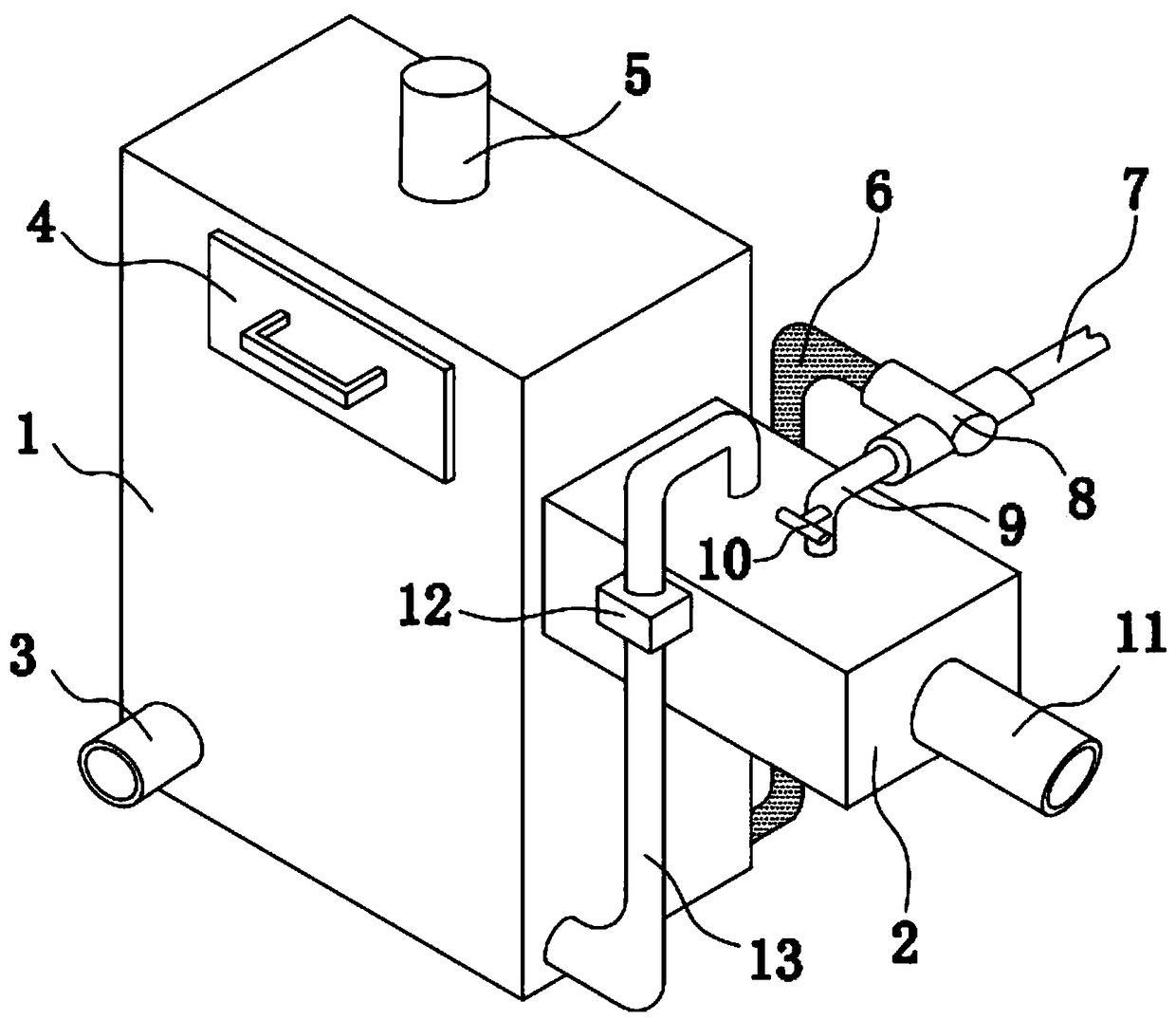

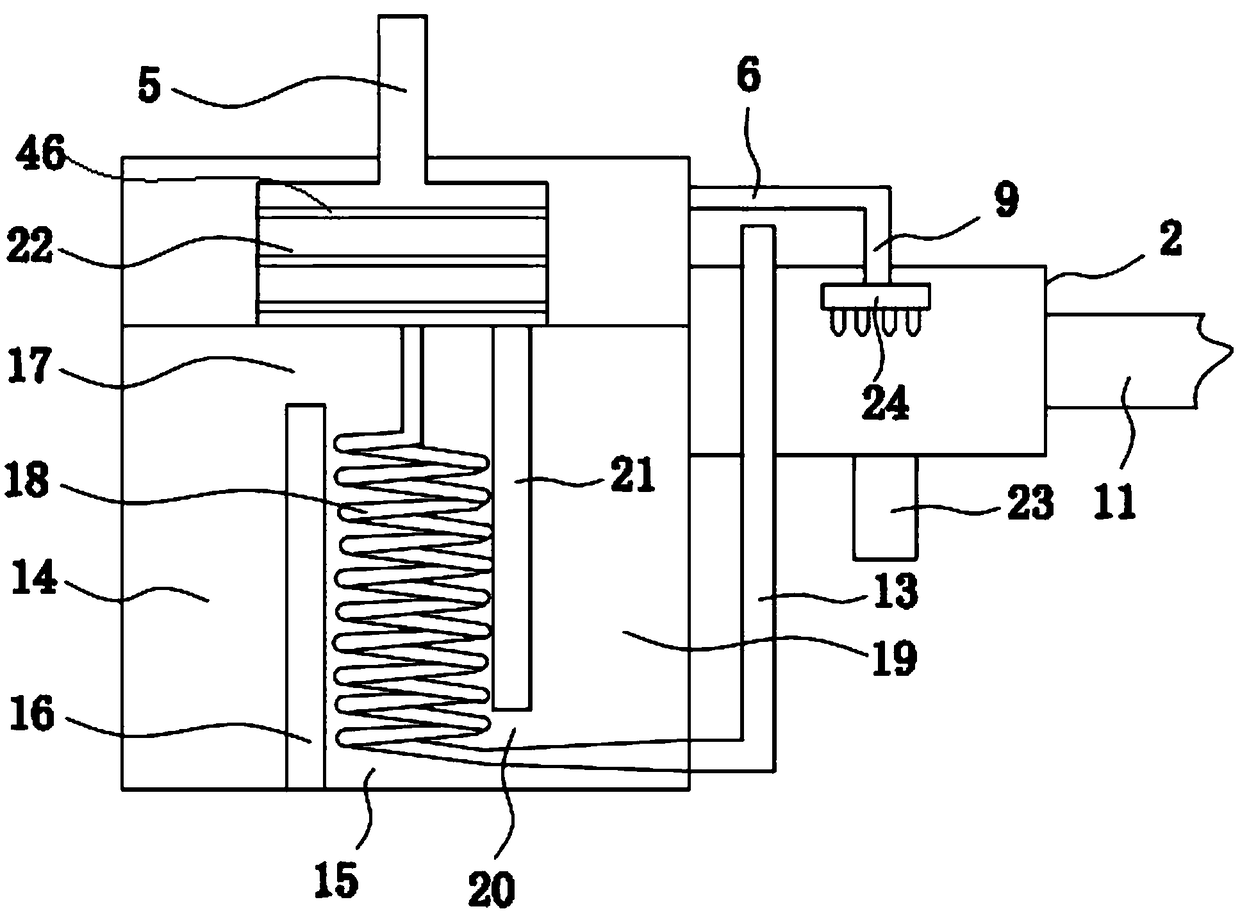

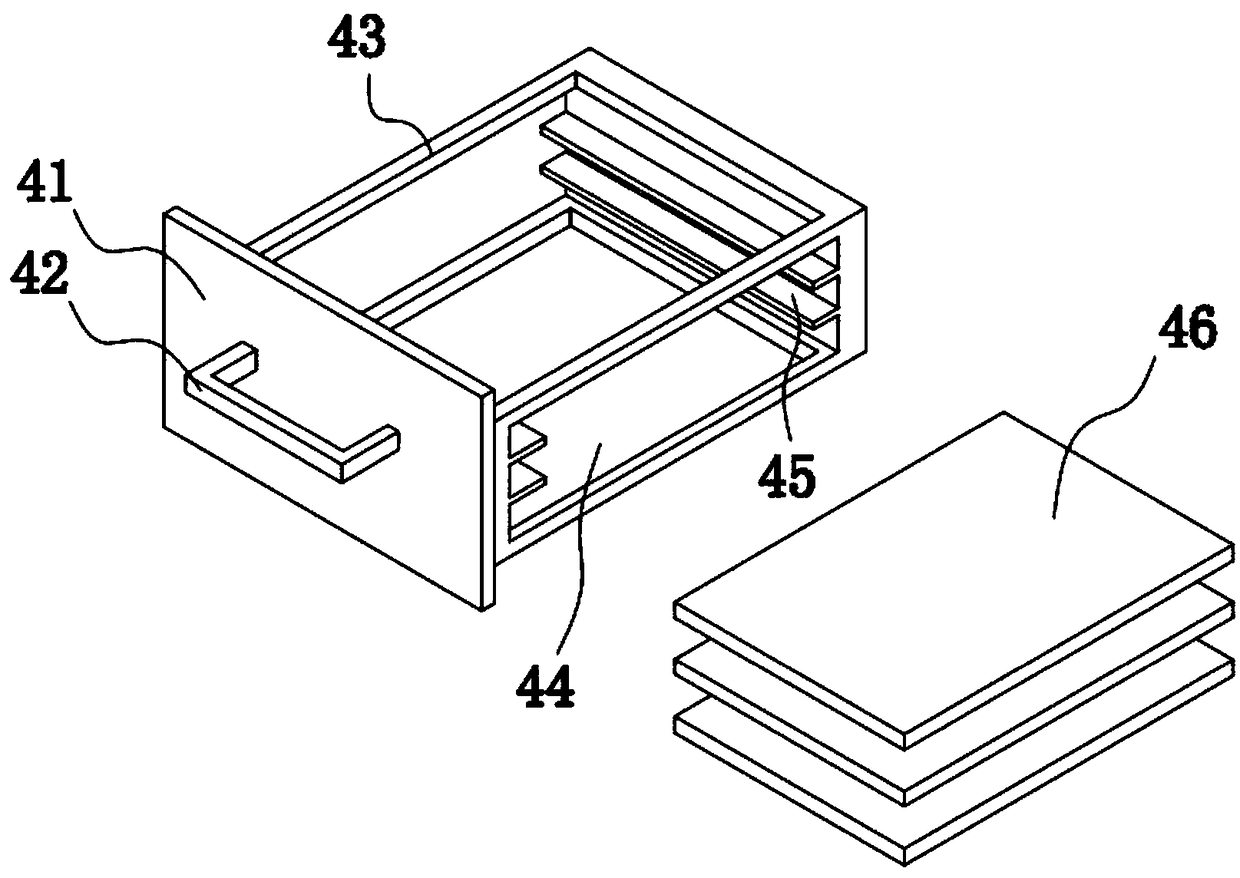

[0020] Such as Figure 1 to Figure 3 As shown, a ship exhaust gas filtration and waste heat recovery utilization device includes a heat exchange box 1 and a spray box 2. The heat exchange box 1 is divided into an exhaust gas cavity 22 and a water injection cavity. The exhaust gas cavity 22 and the water injection cavity are respectively equipped with multiple Layer filter plate 46 (at least three layers) and spiral tube 18, the top inlet of waste gas chamber 22 extends out of heat exchange box 1 through inlet pipe 5, the bottom outlet communicates with the top of spiral tube 18, and the bottom end of spiral tube 18 protrudes through air guide tube 13 The heat exchange box 1 extends into the upstream of the spray box 2, the water injection chamber is respectively connected with the water inlet pipe 3 and the water outlet pipe 6, and the end of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com