Method for correcting track errors generated during iterative learning of industrial robot

An industrial robot and iterative learning technology, which is applied in the field of iterative learning and correction of trajectory errors of industrial robots, can solve the problems of rapid error divergence and failure of learning convergence algorithm, and achieve the effects of improving accuracy, improving trajectory running accuracy and reducing following error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

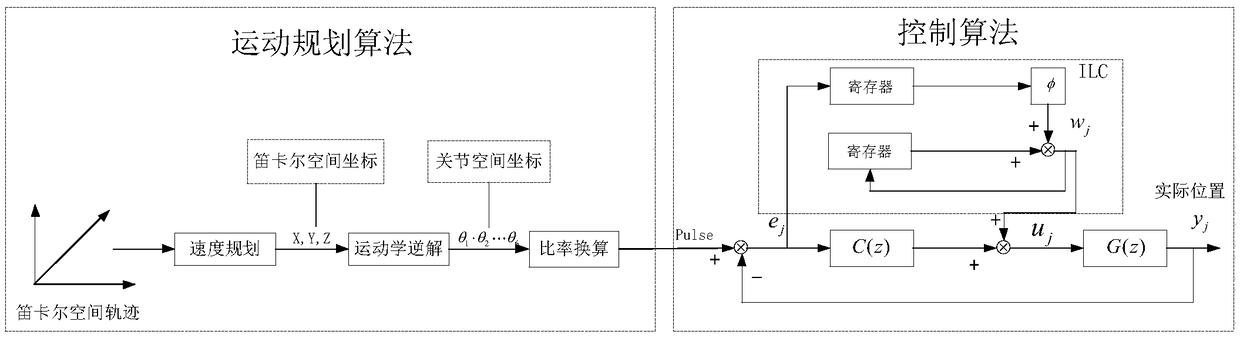

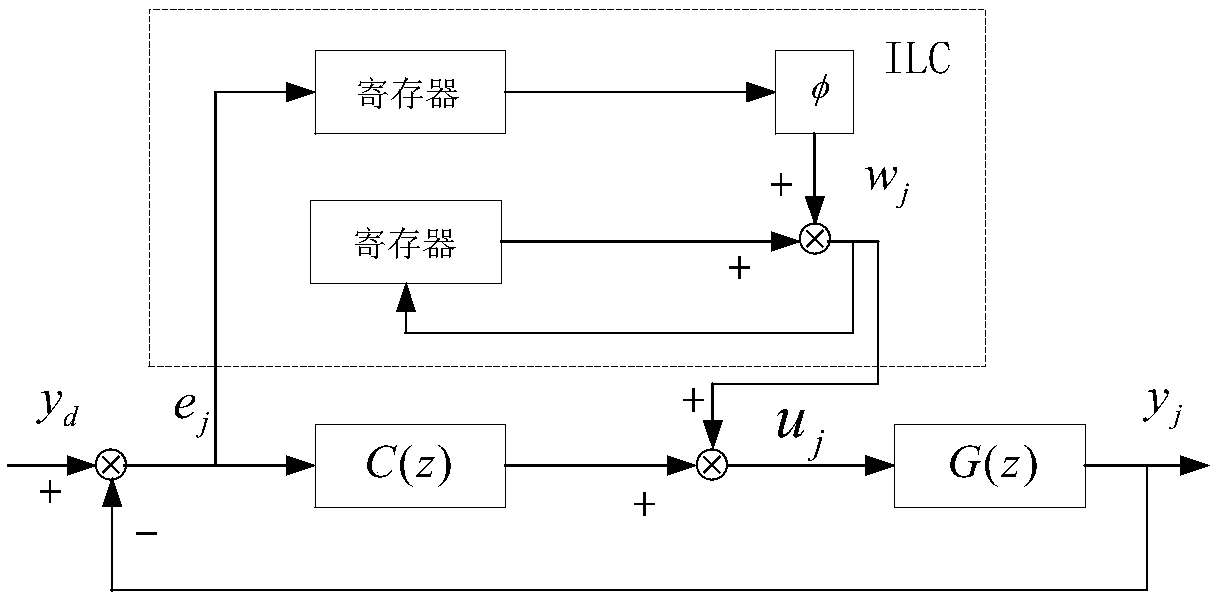

[0063] Such as figure 1 Shown: The motion planning algorithm mainly studies the attitude of the robot's end effector, the route it travels, and the speed planning during the action process, that is, to study what kind of speed and what kind of posture the robot runs on what kind of trajectory. For example, the welding torch of an arc welding robot accelerates at a certain angle, then decelerates at a constant speed, and repeatedly runs a section of straight line welding seam of the automobile shell. In this process, the linear weld seam is firstly discretized into a series of Cartesian space position (position) and time (time) points according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com