Composite material for roof plate of high-speed train

A technology for composite materials and high-speed trains, which is applied in the direction of railway roofs, vehicle parts, and synthetic resin layered products, etc. It can solve the problems of poor sound insulation and noise reduction effects, heavy roof weight, and poor stiffness and strength, and achieve light specific gravity. Impact force, sound insulation and flame retardant performance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

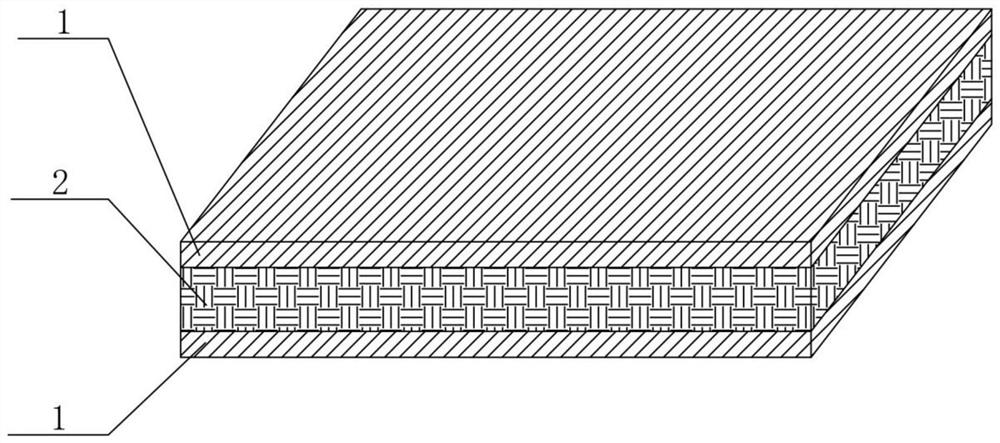

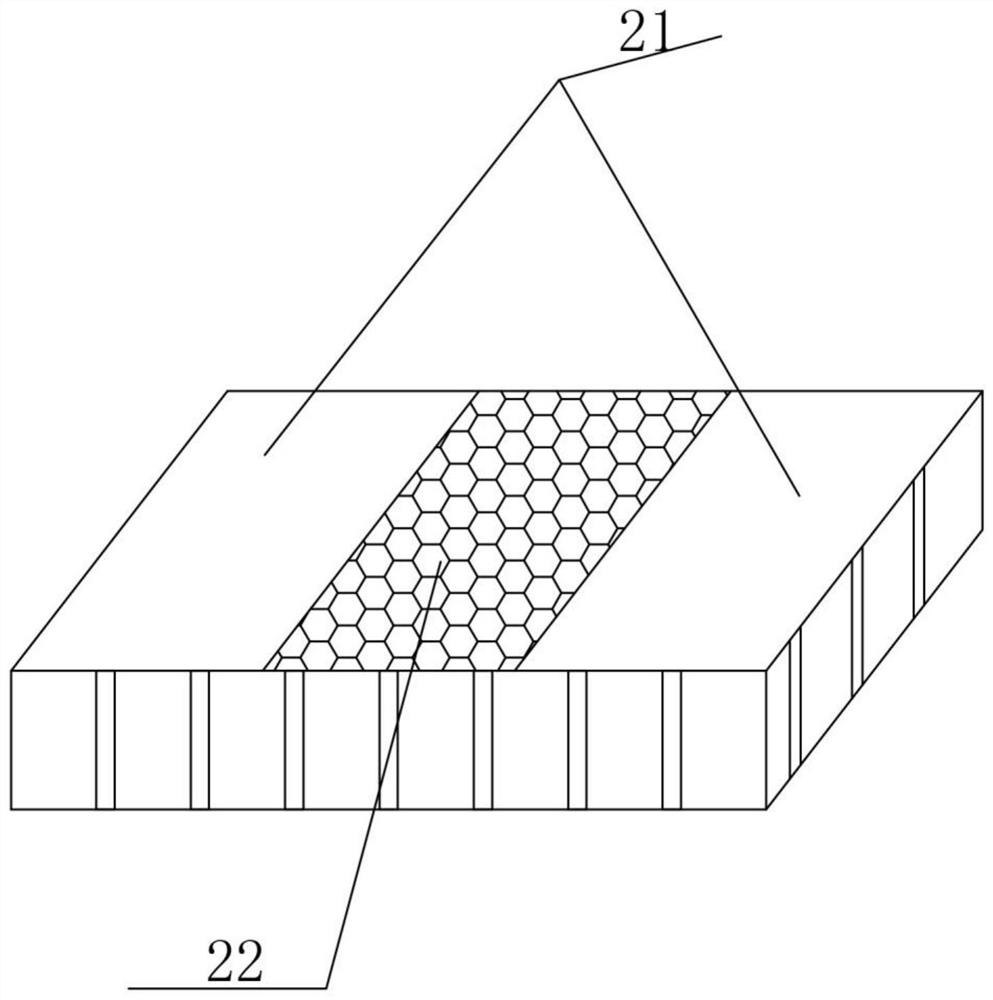

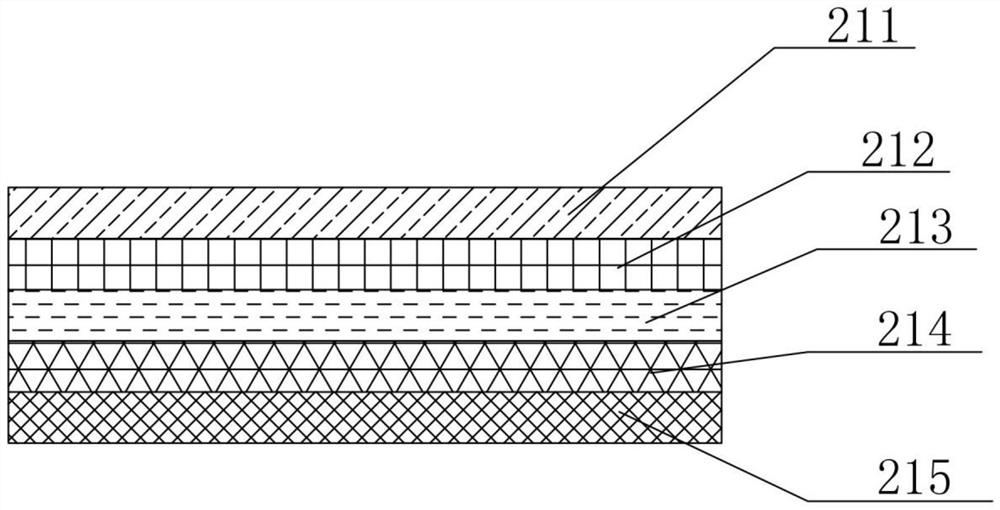

[0023] A composite material for the roof plate of a high-speed train, comprising an outer aluminum plate 1, a reinforced composite material 2, and an inner aluminum plate 3, the reinforced composite material 2 is arranged between the outer aluminum plate 1 and the inner aluminum plate 3, and the reinforced composite material 2 includes a surface reinforced Material 21 and core material 22. The surface reinforcement material 21 includes a sound-insulating and flame-retardant layer 211, a prepreg layer 212, an impact-resistant layer 213, a strength layer 214, and a rigid structure layer 215. The core material 22 is a honeycomb core material.

[0024] The surfaces of the outer aluminum plate 1 and the inner aluminum plate 3 are all treated by spraying paint, which can completely prevent the corrosion of the aluminum plate; The thickness of the inner aluminum plate 3 is 1.5 mm, and the outer aluminum plate 1 and the inner aluminum plate 3 are processed through hardening to improve ...

Embodiment 2

[0026] A composite material for the roof plate of a high-speed train, comprising an outer aluminum plate 1, a reinforced composite material 2, and an inner aluminum plate 3, the reinforced composite material 2 is arranged between the outer aluminum plate 1 and the inner aluminum plate 3, and the reinforced composite material 2 includes a surface reinforced Material 21 and core material 22. The surface reinforcement material 21 includes a sound-insulating and flame-retardant layer 211, a prepreg layer 212, an impact-resistant layer 213, a strength layer 214, and a rigid structure layer 215. The core material 22 is a honeycomb core material.

[0027] Both the surface of the outer aluminum plate 1 and the inner aluminum plate 3 are treated by spraying plastic, which can completely prevent the corrosion of the aluminum plate; the profiles used for the outer aluminum plate 1 and the inner aluminum plate 3 are 5083-H111, and the thickness of the outer aluminum plate 1 is 2.5mm. The t...

Embodiment 3

[0029] A composite material for the roof plate of a high-speed train, comprising an outer aluminum plate 1, a reinforced composite material 2, and an inner aluminum plate 3, the reinforced composite material 2 is arranged between the outer aluminum plate 1 and the inner aluminum plate 3, and the reinforced composite material 2 includes a surface reinforced Material 21 and core material 22. The surface reinforcement material 21 includes a sound-insulating and flame-retardant layer 211, a prepreg layer 212, an impact-resistant layer 213, a strength layer 214, and a rigid structure layer 215. The core material 22 is a honeycomb core material.

[0030] Both the surface of the outer aluminum plate 1 and the inner aluminum plate 3 are treated by spraying paint, which can completely prevent the corrosion of the aluminum plate; The thickness of the inner aluminum plate 3 is 1.8 mm, and the outer aluminum plate 1 and the inner aluminum plate 3 are processed through hardening to improve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com