Dynamic measurement method of rail corrugation

A technology of dynamic measurement and corrugation, applied in the direction of measuring devices, railway vehicle shape measuring devices, railway car body parts, etc., can solve the problem that it is difficult to ensure that the measurement point is always within the effective range of the rail top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

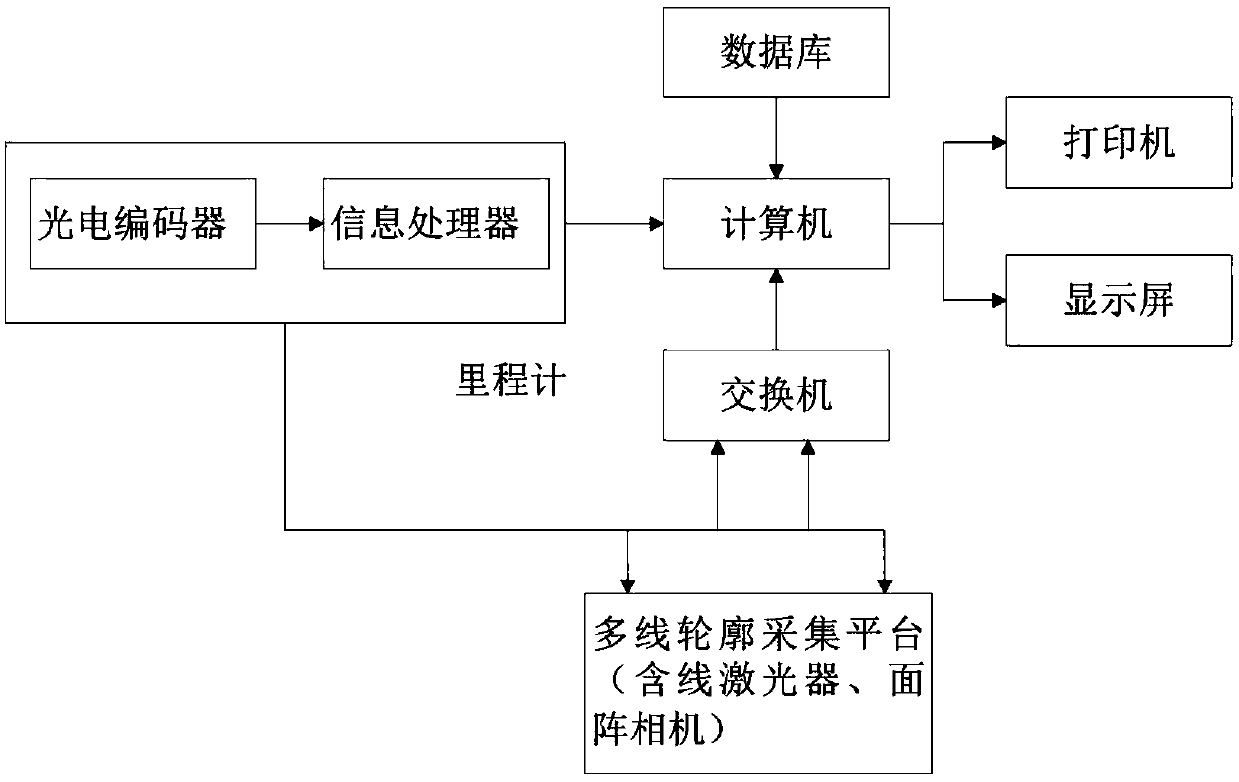

[0037] The dynamic detection system is composed of a multi-line profile acquisition platform composed of multiple line lasers and area array cameras, a data processing platform composed of a comprehensive processing computer and an odometer, and a result output platform composed of a printer and a display. The system block diagram is shown in figure 1 shown.

[0038] During operation, the structured light plane projected by the line laser intersects the rail, forming multiple laser light bar curves containing rail profile information on the rail surface. At the same time, the rotation of the train axle drives the photoelectric encoder to rotate and output the trigger signal, which drives the area array cameras on both sides to complete the synchronous acquisition of light stripe images at equal intervals. After the image is transmitted to the computer through the switchboard, the center line of the light bar is extracted, the image coordinate system is converted to the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com