Cabinet stacking machine with anti-tilting device

A stacker and anti-dumping technology, applied in the field of stackers, can solve the problems of large cabinet size, complex mechanical structure, and small storage quantity, and achieve the effect of good anti-dumping effect, simple mechanical structure and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

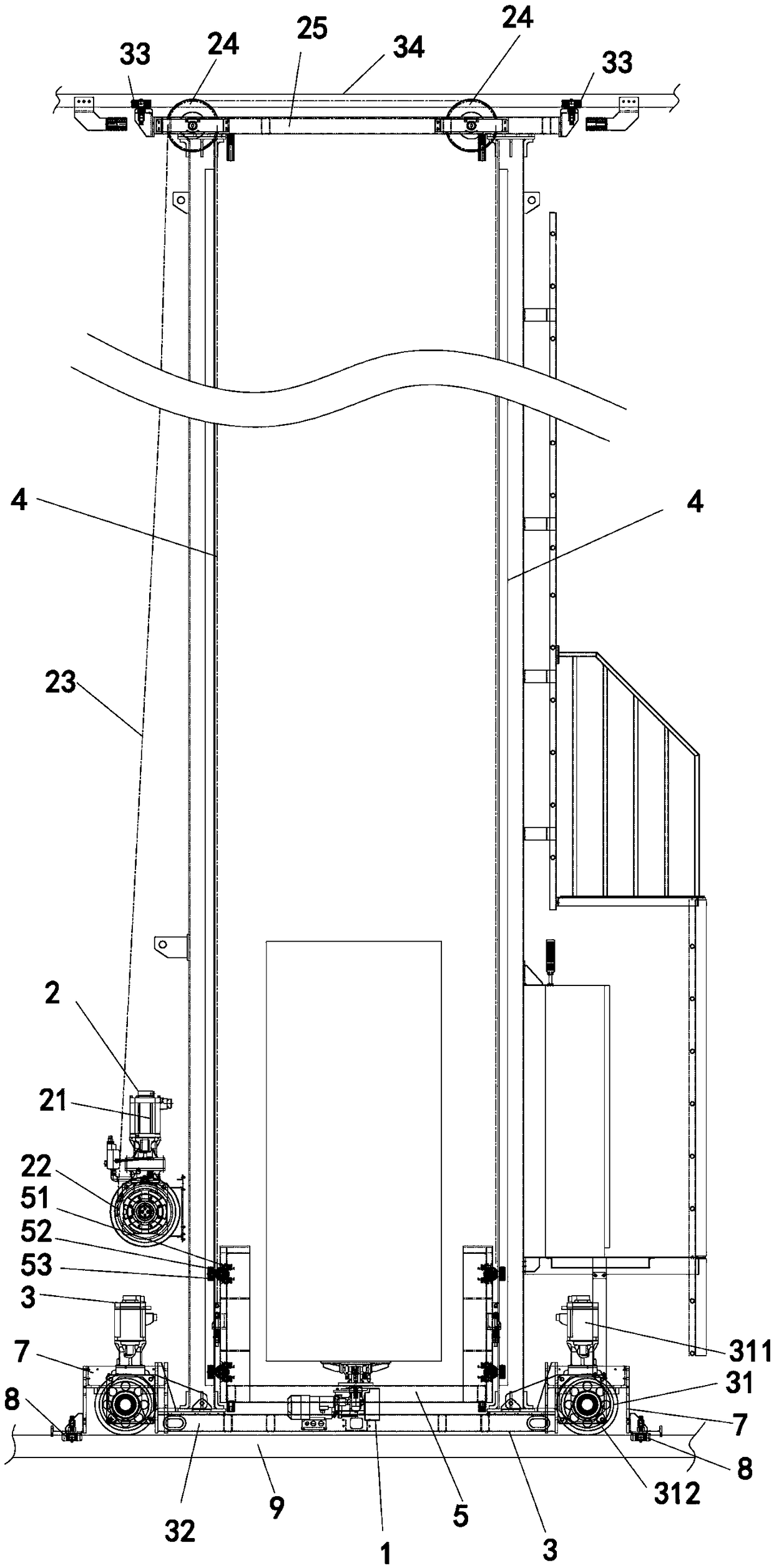

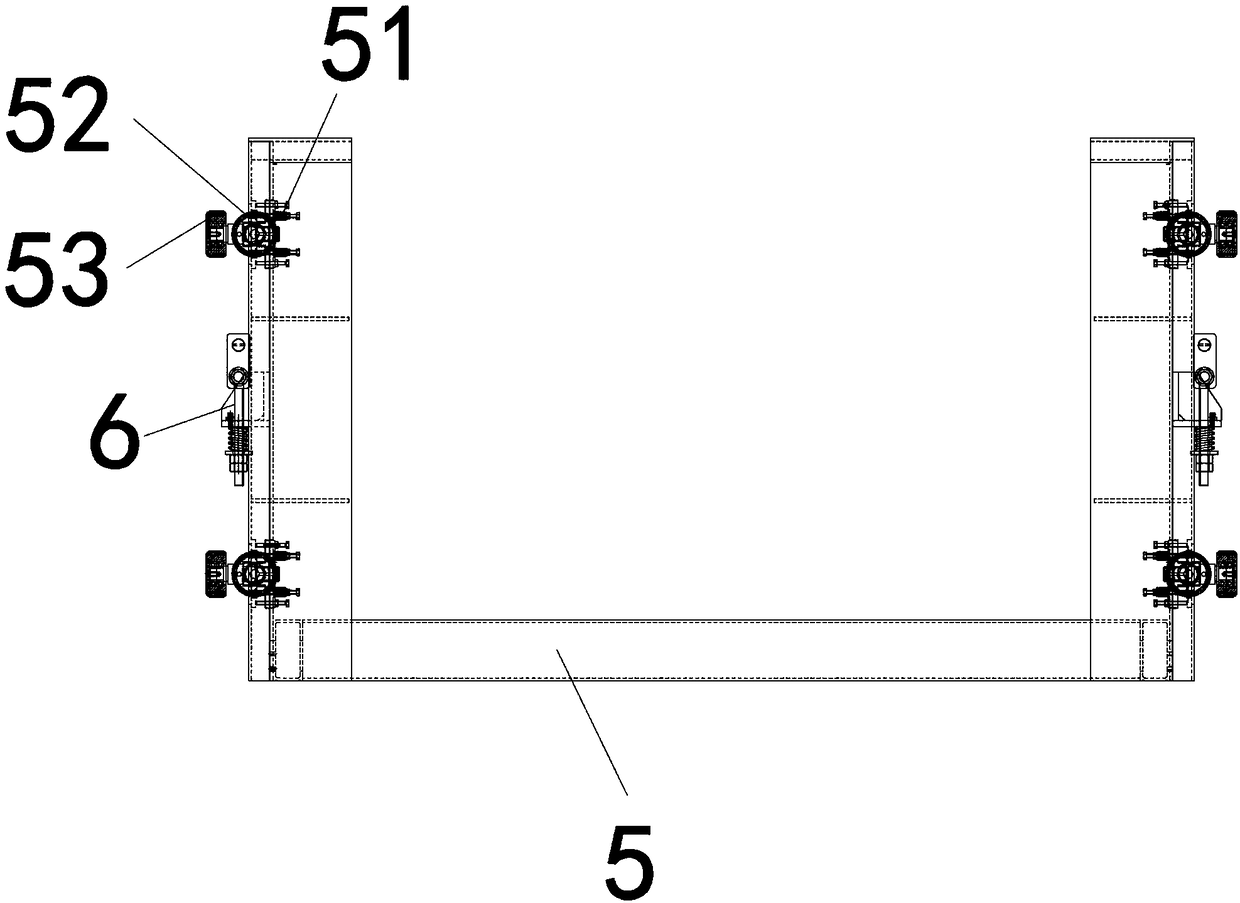

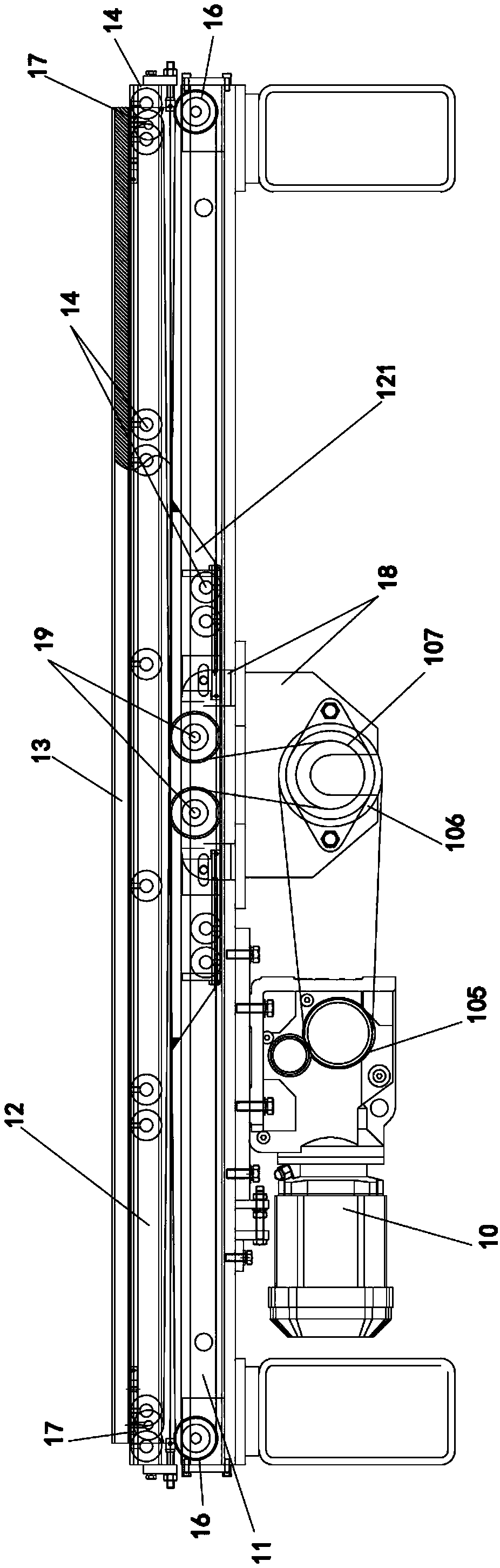

[0027] Such as Figure 1-Figure 9 As shown, a cabinet stacker with an anti-dumping device described in this embodiment includes a lifting mechanism 2, a lateral displacement mechanism 3, a loading platform 5, two columns 4 and a switch cabinet for automatic picking and placing. The telescopic cargo fork 1; the loading platform 5 is located between the two uprights 4, and the positioning rollers 53 on both sides of the loading platform 5 are located in the guide grooves of the uprights 4; the two uprights 4 are fixed on the lateral displacement mechanism 3, and the telescopic cargo The fork 1 is installed on the cargo platform 5, and a plurality of electromagnetic devices 205 are installed on the automatic pick-and-place platform 13 of the telescopic cargo fork 1; Fixed connection. Rolling wheels 52 are installed on both sides of the loading platform 5 through a spring frame 51 , and the rolling wheels 52 are attached to the inner side walls of the columns 4 .

[0028] The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com