A kind of low-density foam material for sports shoes, its preparation method and application

A technology for foaming materials and sports shoes, which is applied in the field of footwear products, can solve the problems that mechanical properties such as tear strength cannot meet the national mechanical standards, and achieve the effect of improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

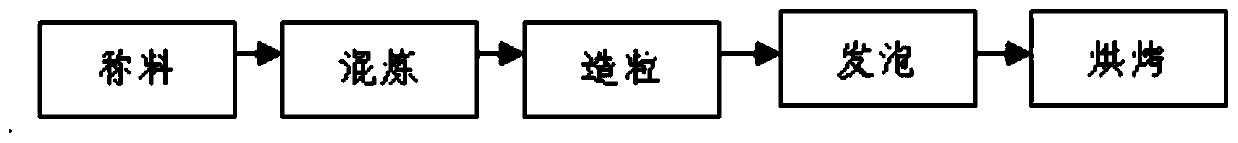

[0051] The embodiment of the present invention provides the preparation method of described low-density foam material for sports shoes, comprising the following steps:

[0052] The components in the material are sequentially kneaded, made and foam-molded to obtain a low-density foam material for sports shoes.

[0053] see figure 1 , figure 1 The process flow chart for preparing the low-density foam material for sports shoes provided by the embodiment of the present invention.

[0054] The embodiment of the present invention first weighs the material, and according to the above-mentioned material formula components and dosage, the peroxide crosslinking agent and the azo foaming agent can be weighed as the first group; the active agent and basic zinc oxide can be used as the second group. The group is weighed; the remaining material components are weighed as the third group.

[0055] In the embodiment of the present invention, the weighed material components are mixed and kne...

Embodiment 1

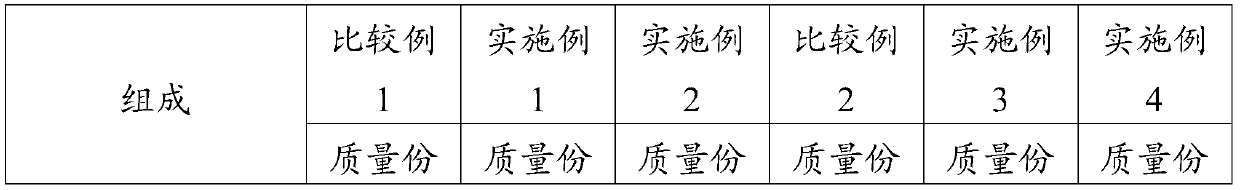

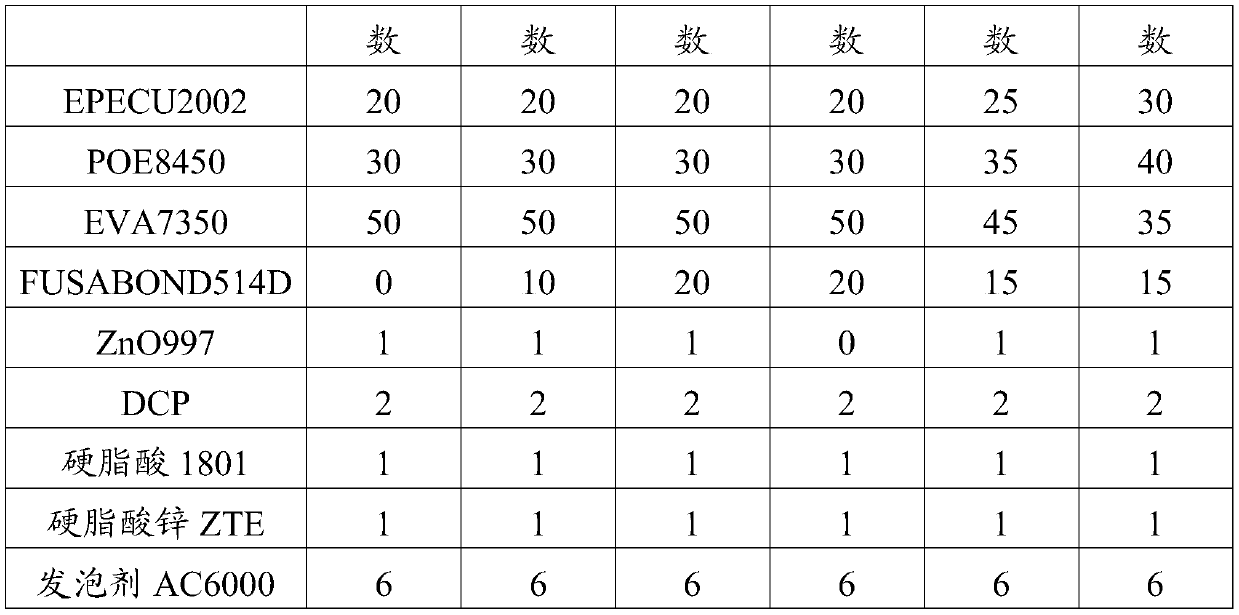

[0062] Adopt the formula described in Table 1, implement according to the following steps:

[0063] According to the composition and dosage of the above-mentioned material formula, the peroxide crosslinking agent and the azo foaming agent are weighed as the first group; the active agent and basic zinc oxide are weighed as the second group; the remaining material groups The points are called as the third group.

[0064] Pour the third group of materials into the internal mixer first, and turn on the machine, when the temperature rises to 80-85°C, pour the second group of materials, and then pour the first group when the temperature rises to 90-95°C When the temperature rises to 100-105°C, pour out the mixed material.

[0065] Pour the mixed material into the material maker, and adjust the temperature of the first, second, third, and fourth zones to 75, 80, 85, and 90°C respectively. And the screw speed is adjusted to 40-50 rpm, and the cutting speed is adjusted to 15-20 rpm. ...

Embodiment 2~4

[0073] The formulations described in Table 1 were used to prepare according to the steps of Example 1 respectively to obtain foaming materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com