Composite anticorrosive and antibacterial sustained-release thin film and preparation method thereof

An anti-corrosion, anti-bacterial, and thin-film technology, applied in the field of composite materials, can solve the problems of pollution, short service life, easy decomposition, etc., and achieve simple and reliable process, improve utilization rate, and prolong the effect of anti-corrosion and anti-bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

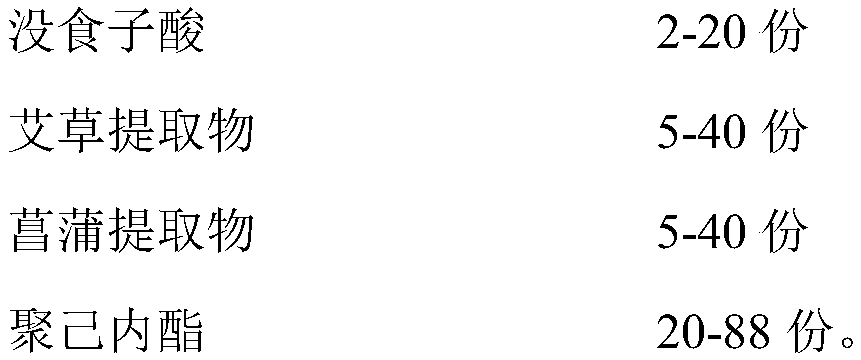

[0022] The composite antiseptic and antibacterial slow-release film of present embodiment, its raw material is as follows by weight parts (100 parts):

[0023]

[0024] All raw materials were mixed uniformly, and formed into a film by hot pressing at 120°C.

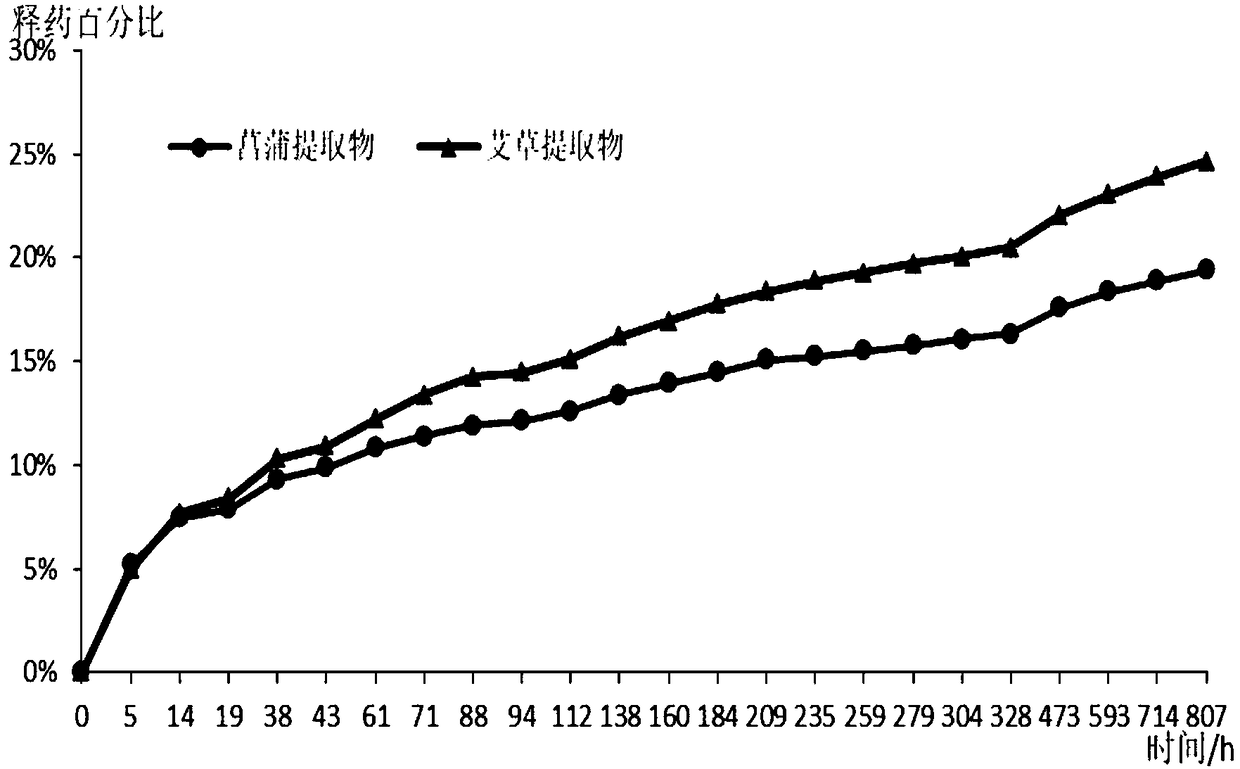

[0025] The drug sustained-release curve of the composite antiseptic and antibacterial slow-release film of the present embodiment is as follows: figure 1 As shown, within 800 hours, both the wormwood extract and the calamus extract can be released continuously, and the drug release percentage at 800 hours is only about 20%.

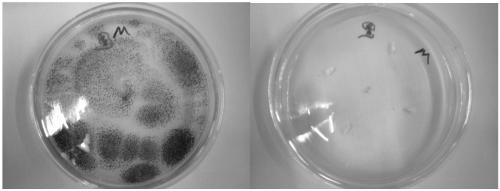

[0026] The anticorrosion and antibacterial properties of the compound anticorrosion and antibacterial sustained-release film of this embodiment are shown in figure 2 As shown, by comparing the photos after 7 days of black mold growth, it can be seen that the antibacterial property of this embodiment is very obvious.

Embodiment 2

[0028] The composite antiseptic and antibacterial slow-release film of this embodiment, its raw material is as follows by weight part:

[0029]

[0030] All raw materials are mixed uniformly, and formed into a film by hot pressing at 160°C.

Embodiment 3

[0032] The composite antiseptic and antibacterial slow-release film of this embodiment, its raw material is as follows by weight part:

[0033]

[0034] All raw materials were mixed evenly, and formed into a film by hot pressing at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com