Coke oven smoke dust fullytotally-closed centralized collection and treatment apparatus

A technology of smoke and dust collection and treatment device, which is applied in coking ovens, furnaces to prevent/remove fouling, and petroleum industry, etc. It can solve the problems of surrounding environmental hazards and the lack of good control methods for fugitive smoke and dust, so as to eliminate potential safety hazards, Prevents damage and enhances the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

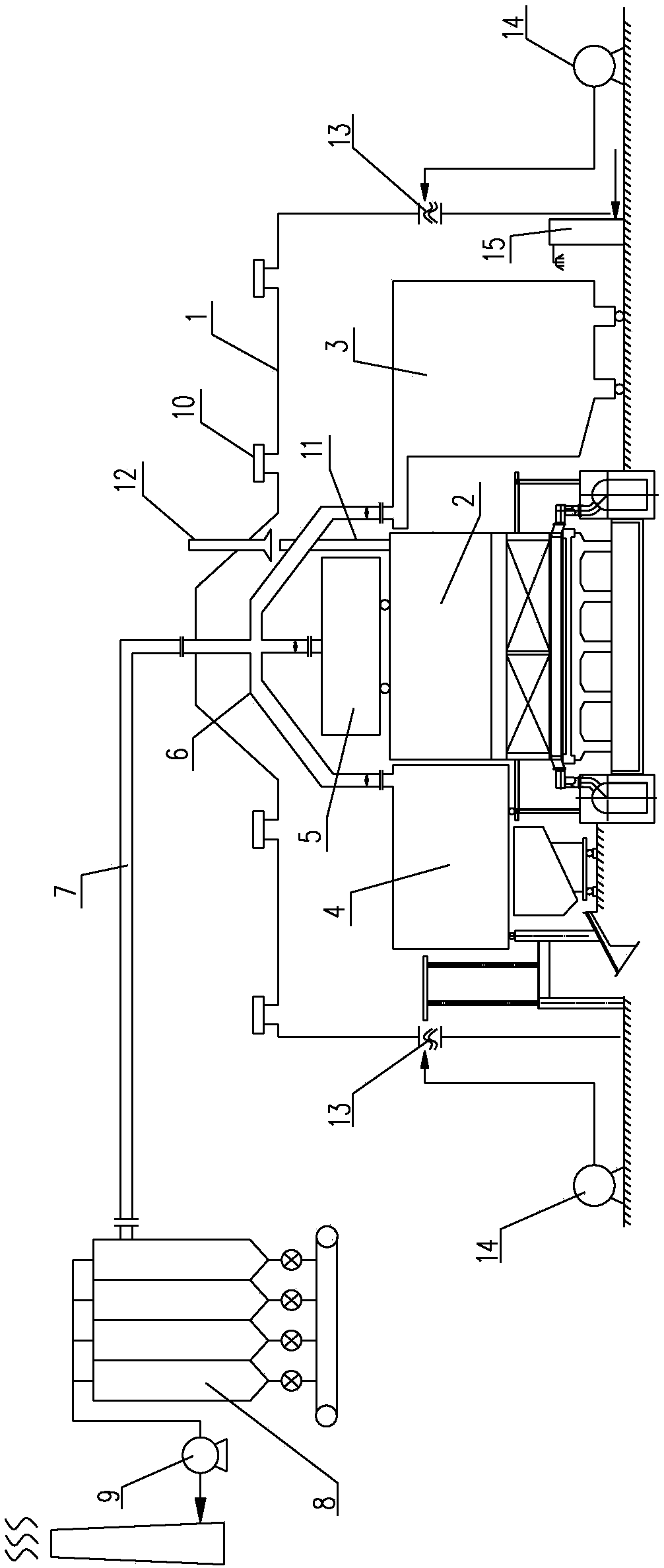

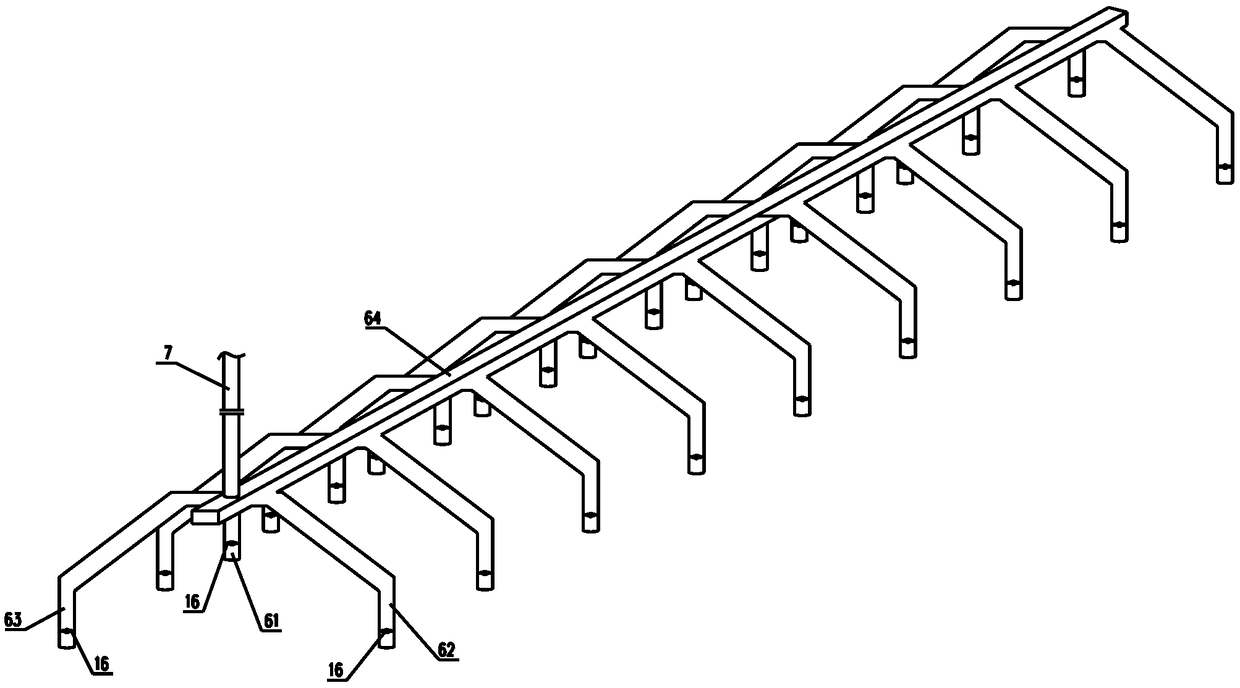

[0027] Such as figure 1 , figure 2 As shown, a coke oven fume fully enclosed centralized collection and processing device according to the present invention includes a fully enclosed soot collection cover 1 and a dust collection pipe network 6; All are enclosed inside, and a dust collection pipe network 6 is arranged on the top of the dust collection cover 1. The dust collection pipe network 6 includes a dust collection pipe 61 for coal loading on the furnace top, a dust collection pipe 62 for pushing coke at the machine side, a dust collection pipe 63 for coke discharge at the coke side and Smoke and dust collection main pipe 64; the roof area, machine side and coke side of each hole of the coke oven 2 are respectively provided with furnace top coal charging smoke and dust collection pipe 61, machine side coke pushing smoke and dust collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com