Epsilon phase modification agent in zinc-copper alloy and modification method

A technology of copper alloy and modifier, applied in the field of alloy materials, to achieve the effects of convenient operation, reduced grain size, and increased number of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The modification treatment method of ε-phase dendrites in the Zn-8Cu alloy (the mass percentage of Cu in the alloy is 8%, and the liquidus temperature is about 530°C), the specific steps are as follows.

[0033] (1) Melt the Zn-8Cu alloy to 590°C to obtain a Zn-8Cu alloy melt.

[0034] (2) Add a certain amount of pure bismuth into the above melt so that the mass percentage of bismuth element in the alloy is 0.5%, and then stir the melt.

[0035] (3) After 8 minutes, stir the alloy melt again to make the bismuth element evenly distributed in the melt. Then the above melt is poured into the mold, and the modified zinc-copper alloy is obtained after cooling.

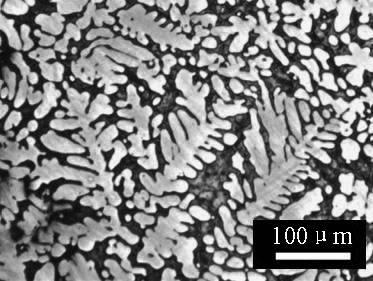

[0036] In this example, before the Zn-8Cu alloy is modified, the ε phase branches are well developed, and the size of the primary dendrite is more than 200 μm, and the primary dendrite contains a large number of secondary dendrites (the size can reach more than 100 μm) and a small amount of tertiary dendrites ( fig...

Embodiment 2

[0038] The modification treatment method of the epsilon phase dendrite in the Zn-8Cu alloy (the mass percentage of Cu in the alloy is 8%), the specific steps are as follows:

[0039] (1) Melt the Zn-8Cu alloy to 615°C to obtain a Zn-8Cu alloy melt.

[0040] (2) Add a certain amount of pure bismuth into the above melt, so that the mass percentage of bismuth element in the alloy is 0.1%, and stir to make the bismuth element evenly distributed in the melt.

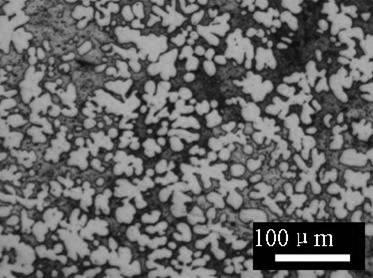

[0041] (3) Then pour the above melt into a mold, and obtain a modified zinc-copper alloy after cooling.

[0042] In this example, before the modification of the Zn-8Cu alloy, the ε phase branches are developed, and the size reaches more than 200 μm. After the modification by the method of this example, the ε phase grain branches are obviously suppressed and reduced, and the size is only about 70 μm ( image 3 ).

Embodiment 3

[0044] The modification treatment method of the epsilon phase dendrite in the Zn-8Cu alloy (the mass percentage of Cu in the alloy is 8%), the specific steps are as follows:

[0045] (1) Melt the Zn-8Cu alloy to 600°C to obtain a Zn-8Cu alloy melt.

[0046] (2) Add a certain amount of pure bismuth into the above melt, so that the mass percentage of bismuth element in the alloy is 1%, and stir to make the bismuth element evenly distributed in the melt.

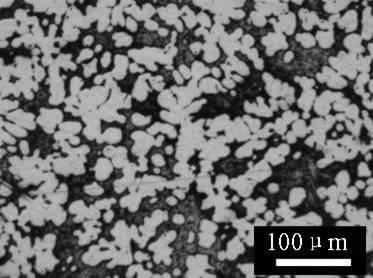

[0047] (3) Then pour the above melt into a mold, and obtain a modified zinc-copper alloy after cooling.

[0048] In this example, before the Zn-8Cu alloy is modified, the ε phase branches are developed, and the size reaches more than 200 μm. After the modification by the method of this example, the ε phase grain branches are significantly reduced, and the size is only about 90 μm ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com