A kind of electroplating device and method of pcb circuit board

A technology for circuit boards and electrolytic cells, which is used in plating tanks, electrodes, electrolytic components, etc. to achieve the effect of improving convection speed and accelerating the balance of concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

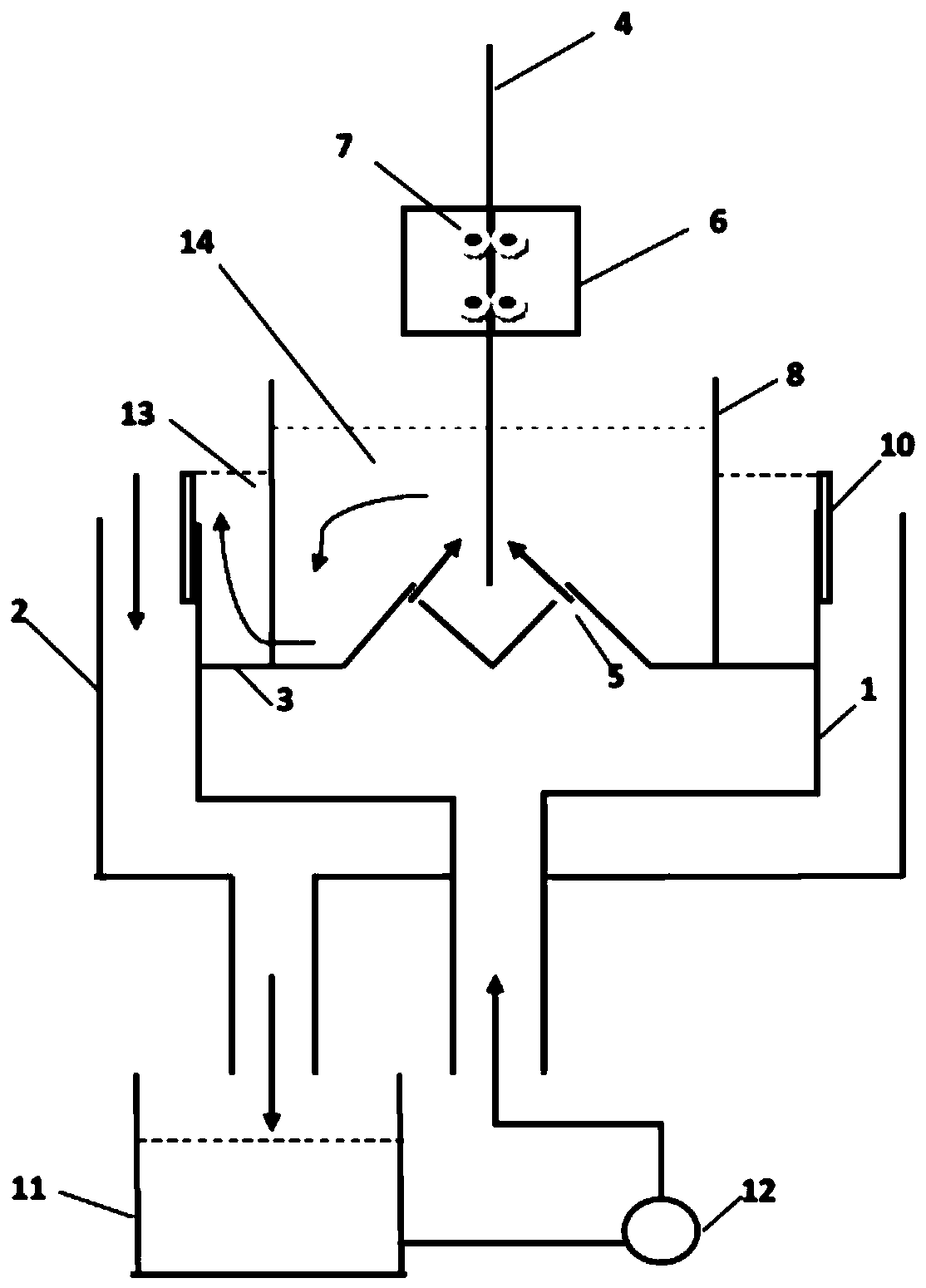

[0034] A circuit board electroplating method in which the electrolyte is forced to circulate. The electrolyte in the electrolyte storage tank 11 is pumped into the lower space of the electrolytic tank 1 through the circulation pump 12, and the tapered hole on the separator 3 provided in the middle of the electrolytic tank 1 5 is sprayed out (the angle between the outlet of the tapered hole 5 and the circuit board 4 is 45°), and the electrolyte meets the resistance of the circuit board 4 and turns back down to flow through the guide hole 9 under the anode plate 8 , flows into the electrolyte outer tank 13 formed between the anode plate 8 and the baffle plate 10, further crosses the baffle plate 10 arranged on the outer wall of the electrolytic tank 1 (outer tank 13) and flows into the overflow tank 2, and flows into the storage tank from the overflow tank Liquid tank 11, by sliding baffle plate, makes the liquid level of electrolyte outer tank 13 be lower than the liquid level o...

Embodiment 2

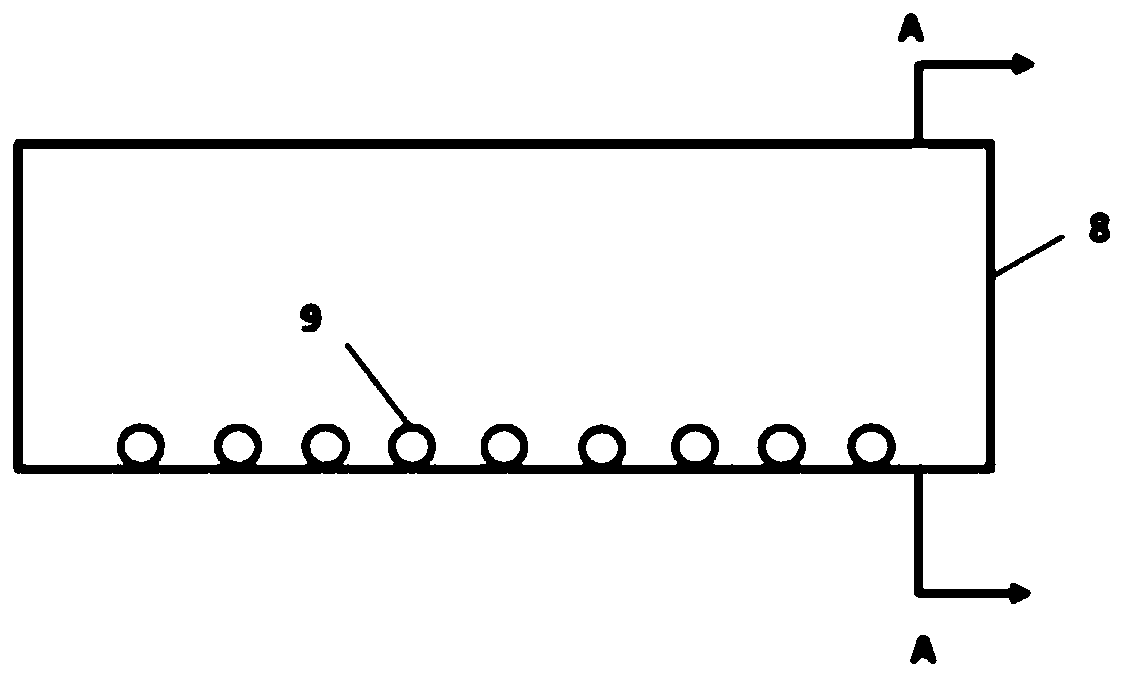

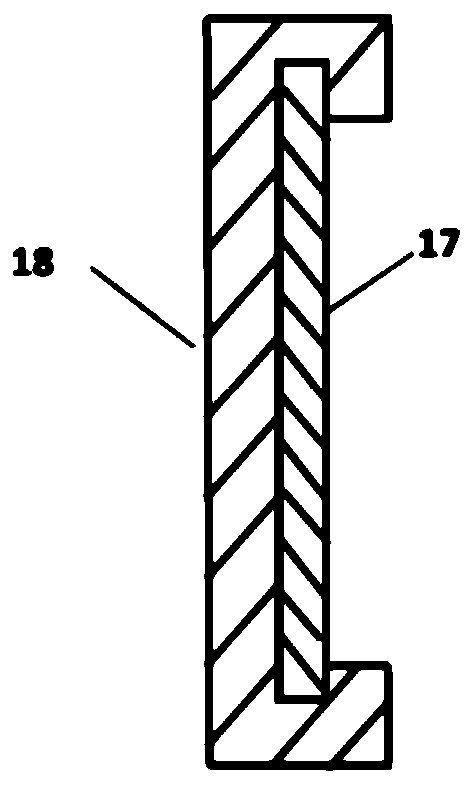

[0036] Realize the circuit board electroplating device of the electrolytic solution forced circulation of above-mentioned electroplating method, see Figure 1-4 , including electrodeposition tank 1, overflow tank 2, electrolytic tank 1 is divided into upper and lower parts by intermediate partition 3, the middle part of intermediate partition 3 is in the shape of an inverted W, and the side near the circuit board 4 is at the sharp ridge of W There is a tapered hole 5, the inner diameter of the tapered hole is 2 mm, the outlet of the tapered hole near the circuit board side is 1 mm in outer diameter, the tapered holes at the sharp ridge of the inverted W are in a row, and the adjacent tapered holes The interval is 5mm, the circuit board 4 is placed above the center of the inverted W, the circuit board is clamped by the elastic member 6, and a conductive member 7 is built in the inner side of the elastic member 6 close to the circuit, and the conductive member 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com