Thermal insulation wall for building energy saving

A building energy-saving and thermal insulation wall technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low energy utilization rate and achieve the effects of sufficient toughness, improved utilization rate and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

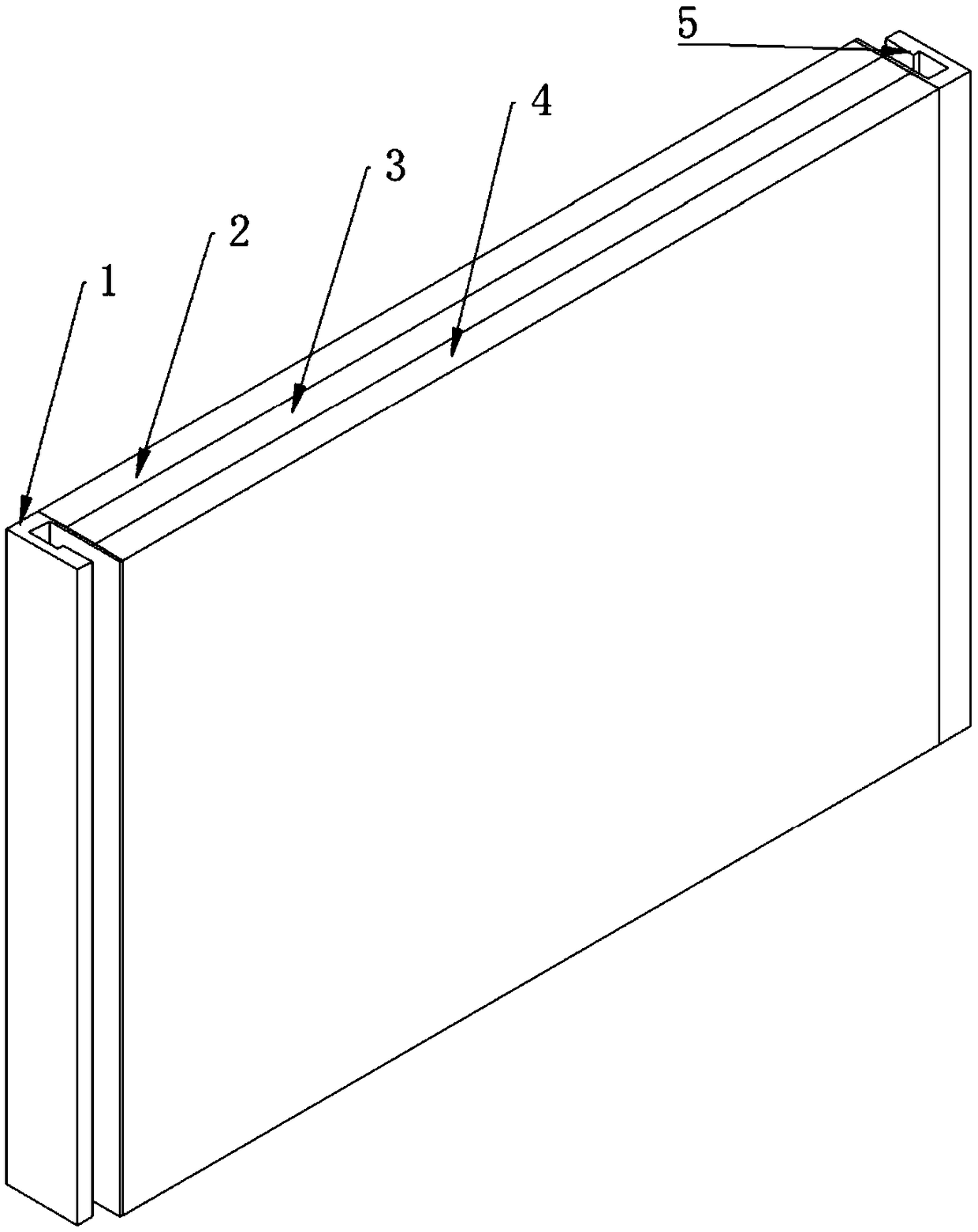

[0019] Embodiment 1 is basically as attached figure 1 Shown: a thermal insulation wall for building energy saving, comprising a plurality of boards spliced together, one end in the width direction of the board is provided with an L-shaped locking board 1, and the other end in the width direction of the board is provided with an L-shaped locking board 1 The L-shaped pinch plate 5 matched with the shaped lock plate 1, in order to prevent the two plates from separating from each other, the L-shaped lock plate 1 and the L-shaped pinch plate 5 are provided with helical teeth that mesh with each other. The plate body includes the outer wall 2. The inner wall 4 and the insulation board 3 between the outer wall 2 and the inner wall 4.

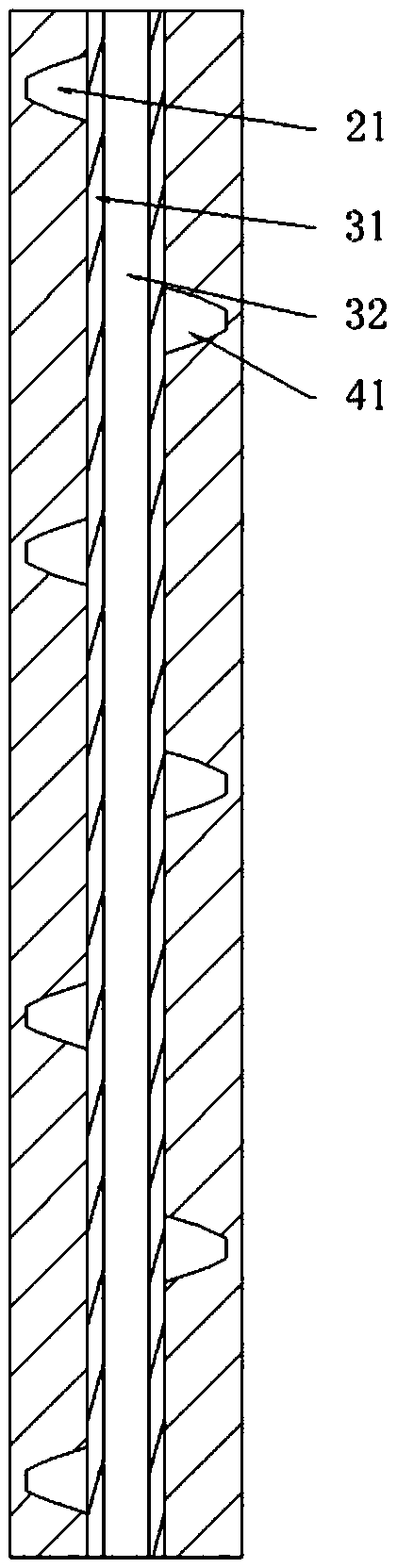

[0020] Such as figure 2 As shown, the outer wall 2 is provided with a plurality of outer wall honeycomb grooves 21 penetrating toward the side of the insulation board 3. The cross section of the outer wall honeycomb grooves 21 is circular, and the ...

Embodiment 2

[0022] The difference between embodiment 2 and embodiment 1 is that the cross-section of the inner wall honeycomb groove 41 and the outer wall honeycomb groove 21 is diamond-shaped, the area of the outer wall honeycomb groove 21 accounts for 40% of the whole board area, and the inner wall honeycomb groove 41 The area accounts for 40% of the entire board area.

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 1 is that the cross section of the inner wall honeycomb groove 41 and the outer wall honeycomb groove 21 is triangular, the area of the outer wall honeycomb groove 21 accounts for 45% of the whole board area, and the inner wall honeycomb groove 41 The area accounts for 45% of the entire board area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com