Vacuum insulation board for cold chain and installation method thereof

A technology of vacuum insulation panels and cold chains, which is applied in covering/lining, construction, building construction, etc. It can solve the problems of color steel plates affecting the service life of cold storage, the decline of thermal insulation performance of cold storage panels, and the decrease of load-bearing capacity of cold storage panels to achieve thermal insulation Good effect, light weight, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

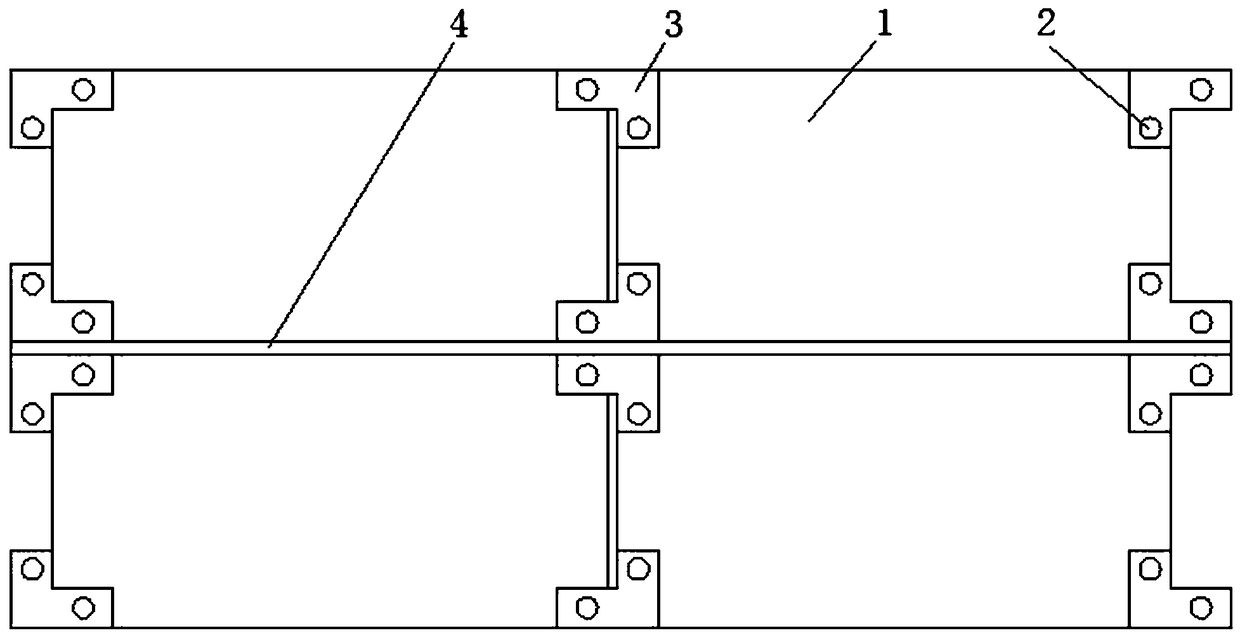

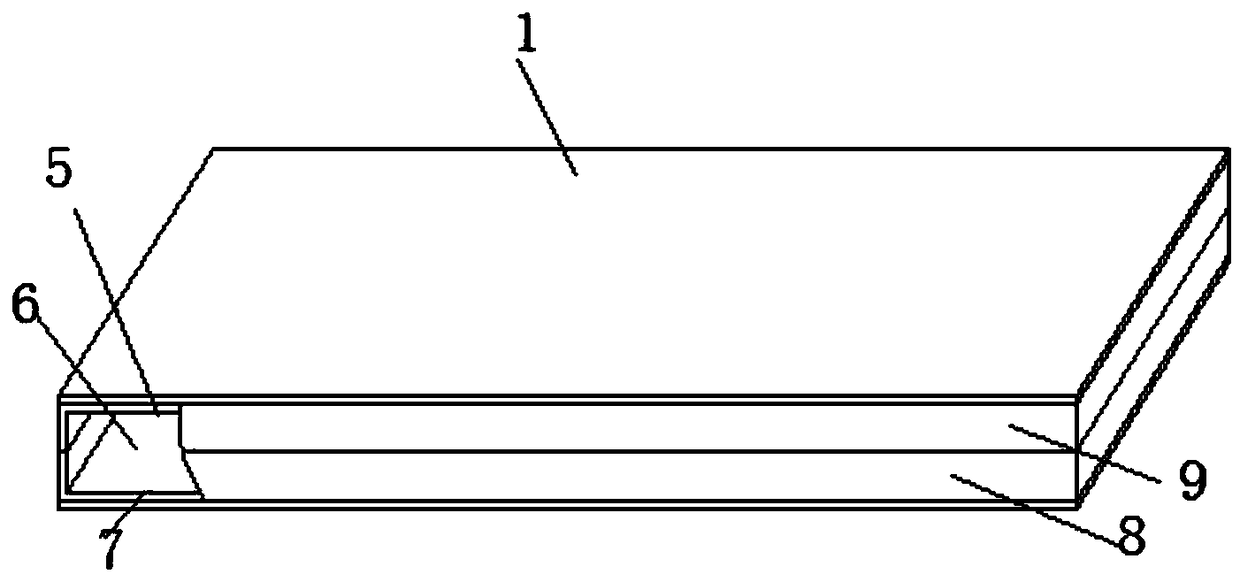

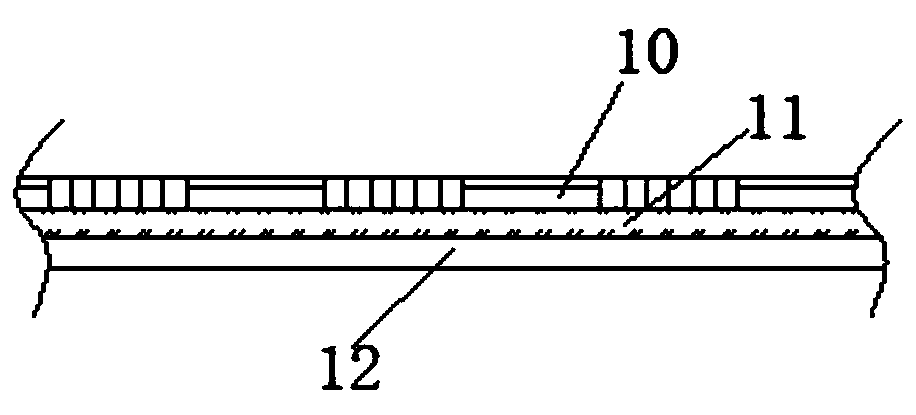

[0025] Such as Figures 1 to 3 As shown, this embodiment provides a vacuum insulation panel for cold chain, including an upper plate and a lower plate made of metal plates, the edge of the upper plate is provided with a downward fold A integrally formed with the upper plate, The edge of the lower plate is provided with an upward fold B integrally formed with the lower plate, and the upper surface of the upper plate and the lower surface of the lower plate are coated with a decorative layer with acid and alkali resistance. A and folded edge B are seamlessly connected with the upper plate and the lower plate to form a sealed cuboid box-shaped plate with a vacuum cavity inside.

[0026] Folded edge A and folded edge B are seamlessly connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com