A Valve Based on Rigid-Flexible Composite Coating and Non-smooth Spatial Disturbance Microstructure

A rigid-flexible compound, non-smooth technology, applied in the direction of fluid flow, fluid pressure actuators, servo motor components, etc., can solve problems such as erosion problems that are difficult to solve, achieve reduced erosion wear, significant noise reduction effects, and lighten The effect of cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

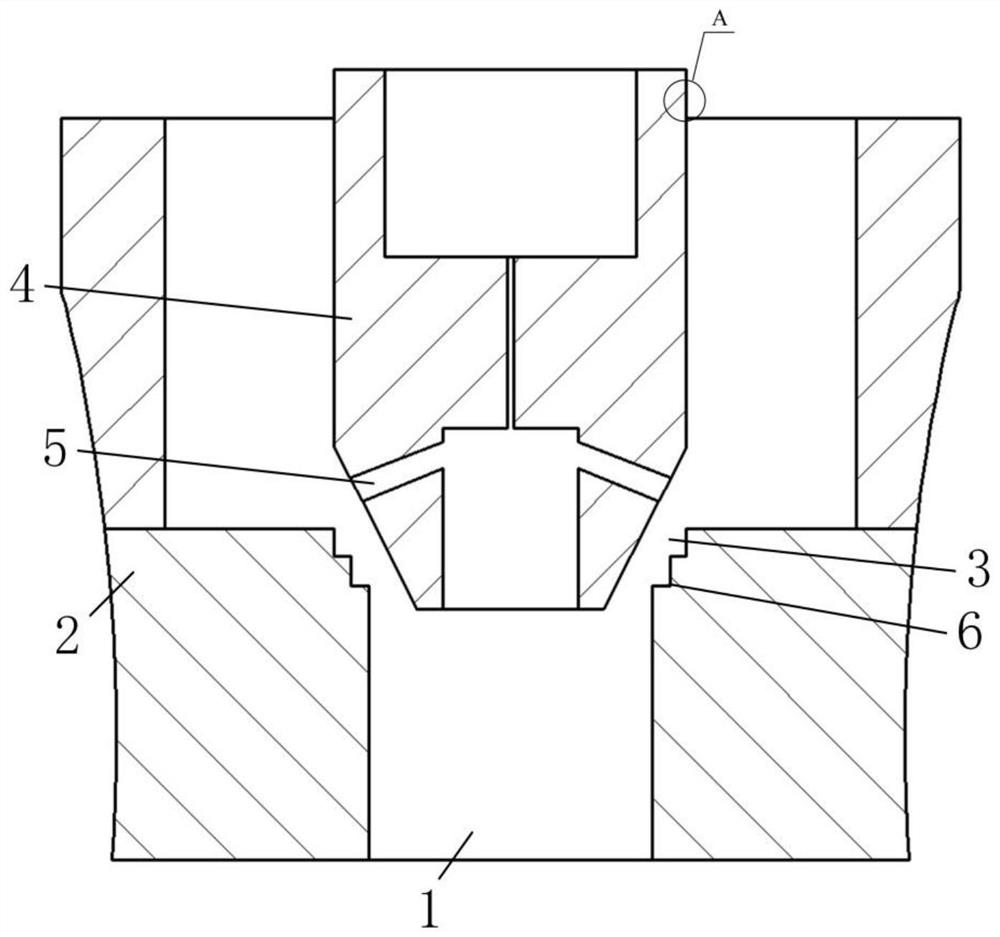

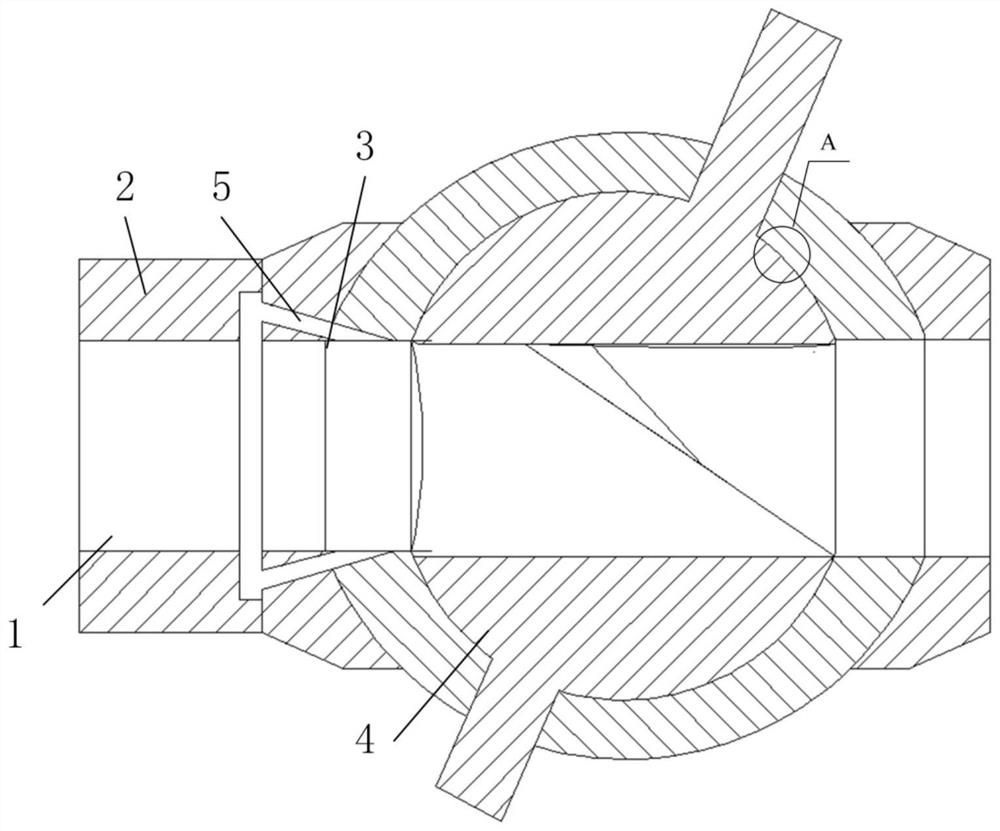

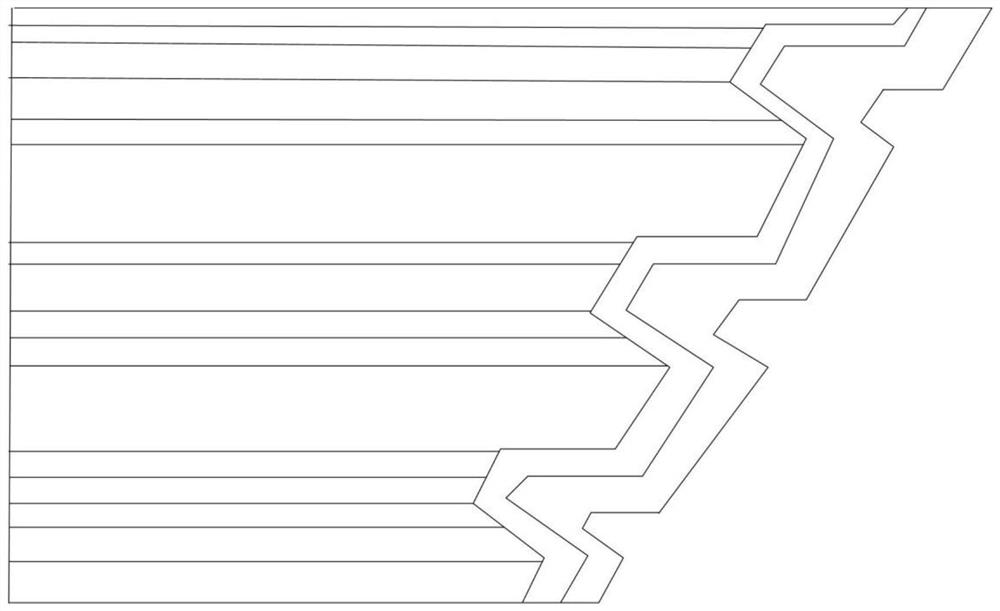

[0018] A valve based on a rigid-flexible composite coating and a non-smooth space spoiler microstructure, which includes a water inlet 1, a valve body 2, a throttle port 3, a valve core 4, a jet drag reduction structure 5, and a non-smooth groove structure 6 , there is a jet drag reducing structure 5 on the spool 4, the side of the spool 4 facing the water inlet 1 is slotted, the side of the spool 4 is non-linearly arranged with jet holes communicating with the groove, the inner surface of the valve body 2 and the spool The surface of 4 is a non-smooth groove structure 6, and the rigid-flexible composite coating is installed distributedly on the non-smooth groove structure 6, and the non-smooth structure and coating technology are used to reduce the damage of components caused by erosion and wear, and reduce the degree of valve failure; A non-linear arrangement of jet holes is established on the valve seat to change the pressure distribution by maximizing flow disturbance, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com