Oil circulation cooling system

A technology of cooling system and oil circulation, applied in engine components, engine lubrication, lubricating parts, etc., can solve the problem of the increase of lubricating oil temperature in the oil pool of the atomizer, the increase of lubricating oil temperature, and the cooling of the bearing by the lubricating oil. Problems such as the disappearance of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

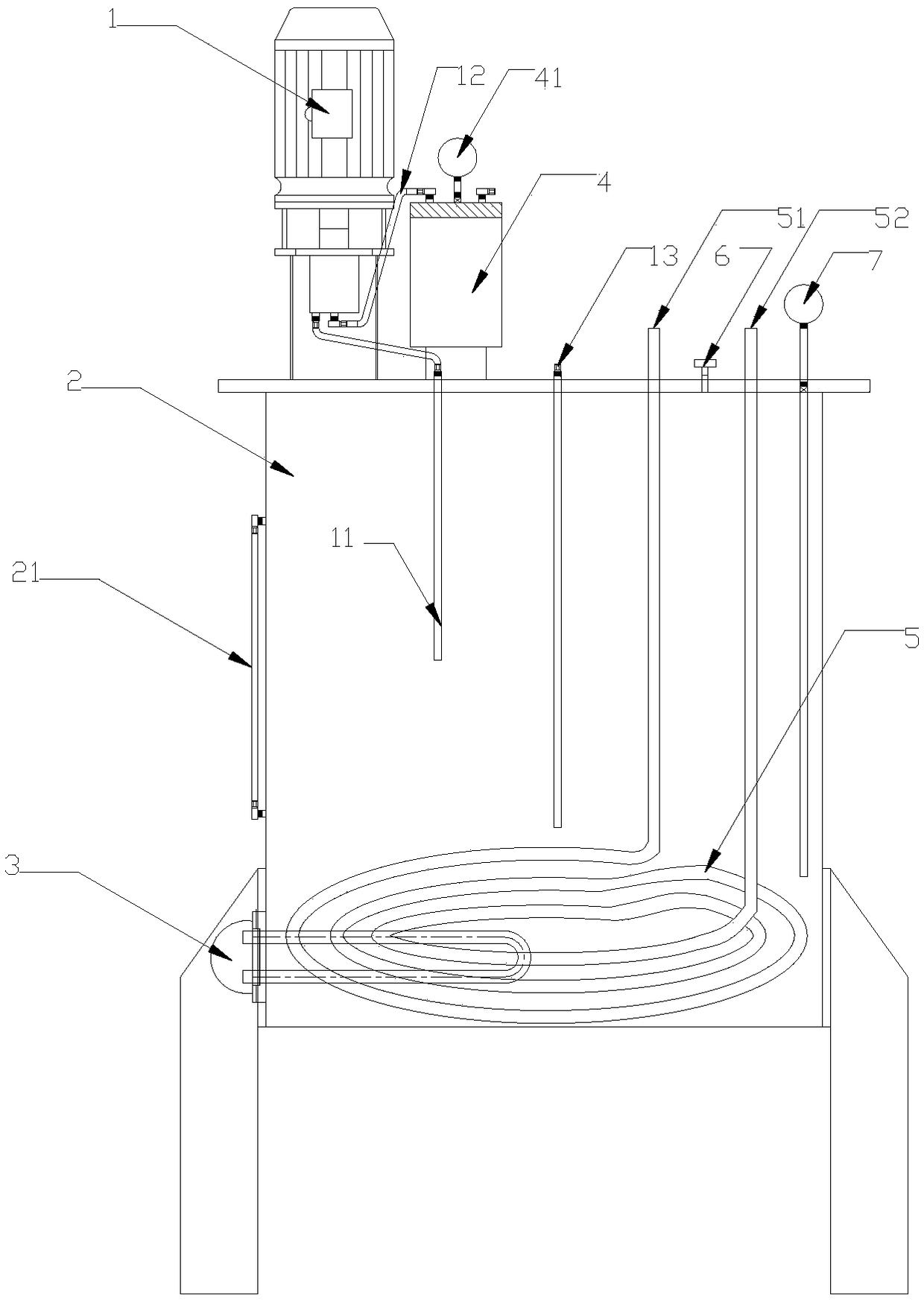

[0017] figure 1 It is a schematic diagram of the present invention. like figure 1 As shown, an oil circulation cooling system includes an oil pump 1, an oil suction pipe 11-12, an oil suction pipe 13, an oil tank 2, a heater 3, an oil tank 4, an oil tank pressure gauge 41, a cooling water pipe 5, an air vent 6 and an oil tank Thermometer7. The oil pump 1 is installed on the oil tank 2 . The side wall of the oil tank 2 is equipped with an oil tank level gauge 21. The fuel tank level gauge 21 is transparent, and the liquid level of the fuel tank 2 can be seen at the transparent part. The top of the fuel tank 2 offers air vents 6 . One end of oil extraction pipe 13 stretches in the fuel tank 2, and the other end of oil extraction pipe 13 stretches in the oil pump of the atomizer not shown among the figure. The atomizer is the prior art, not the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com