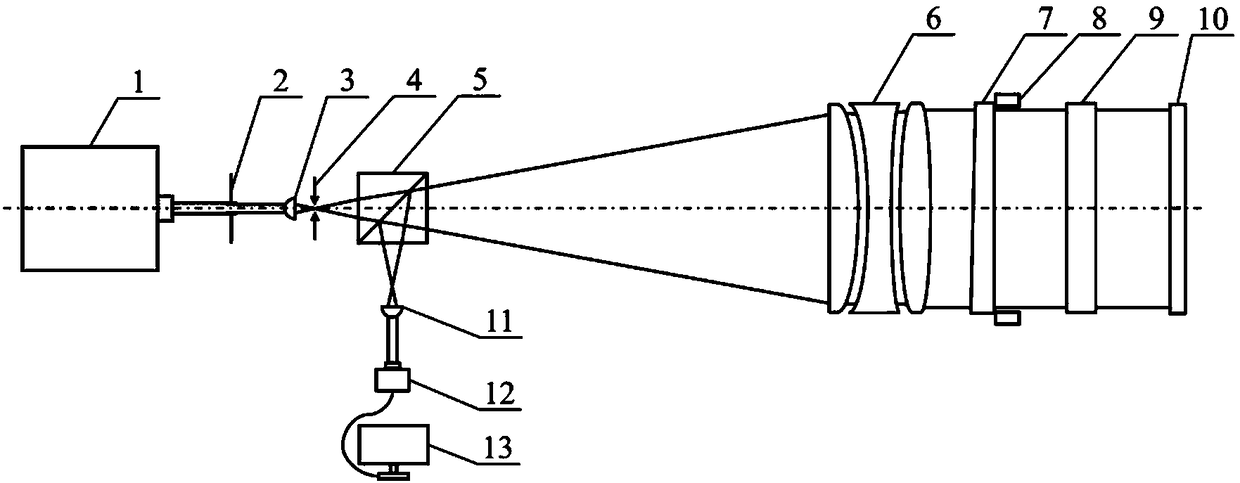

Multi-wavelength laser interferometer

A laser interferometer and multi-wavelength technology, applied in the direction of instruments, optical devices, measuring devices, etc., to achieve the effect of large processing and assembly tolerance range, reduce difficulty, and reduce processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

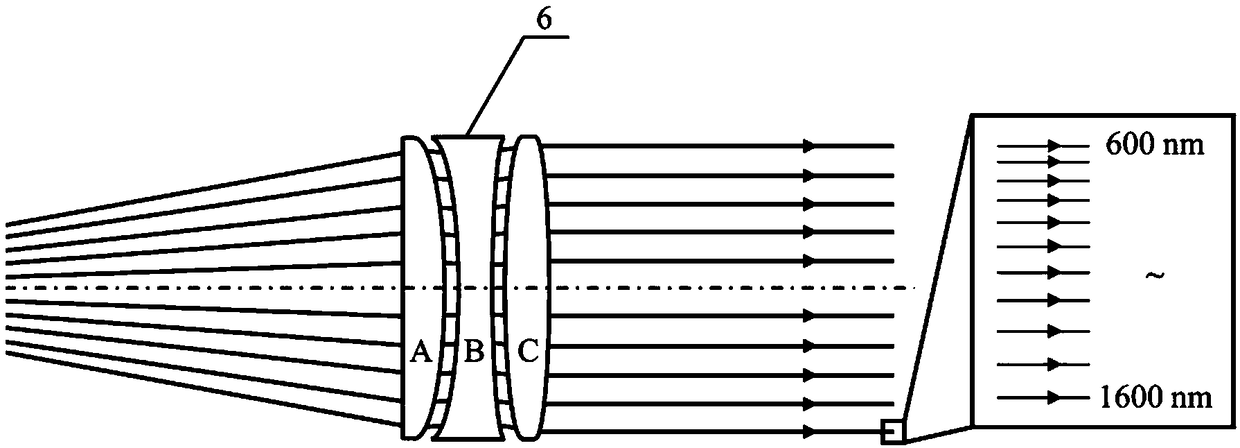

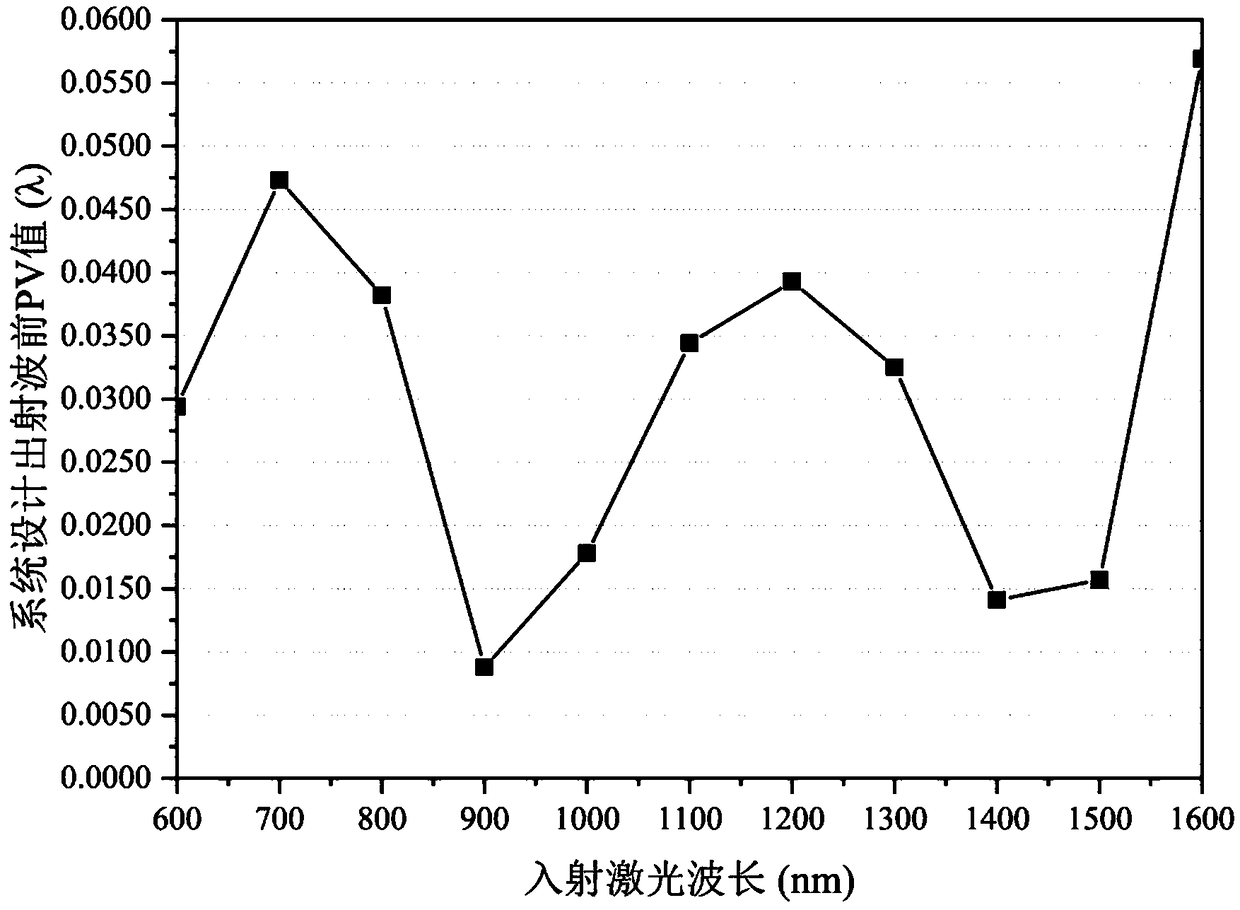

[0024] Example 2, figure 2 It is a schematic diagram of the relationship between the height of the marginal ray (Marginal ray) of the output beam of the multi-wavelength laser interferometer with an output aperture of 130 mm and the input laser wavelength in Embodiment 2 of the present invention. It can be seen from the figure that when the output wavelength of the laser 1 changes within the range of 600nm to 1600nm, there is no need to move, adjust or change the beam expander secondary mirror 3, beam splitting prism 5 or collimating primary mirror described in this device 6. The device can output collimated beams at every wavelength. In the present embodiment, the three lenses in the collimating primary mirror 6 are composed of three different glass materials respectively, adopt positive, negative, and positive lens combinations, have super-achromatic (Super-achromatic) ability, and can be extremely Eliminate the chromatic aberration introduced by the ultra-wideband to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com