Ship seawater pipeline anode iron flange corrosion resistance test system and method

A corrosion resistance and test system technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems that affect the normal operation of pipeline equipment and threaten the safety of ships, and achieve significant production practice significance, Improve the potential difference, adjust the working conditions and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

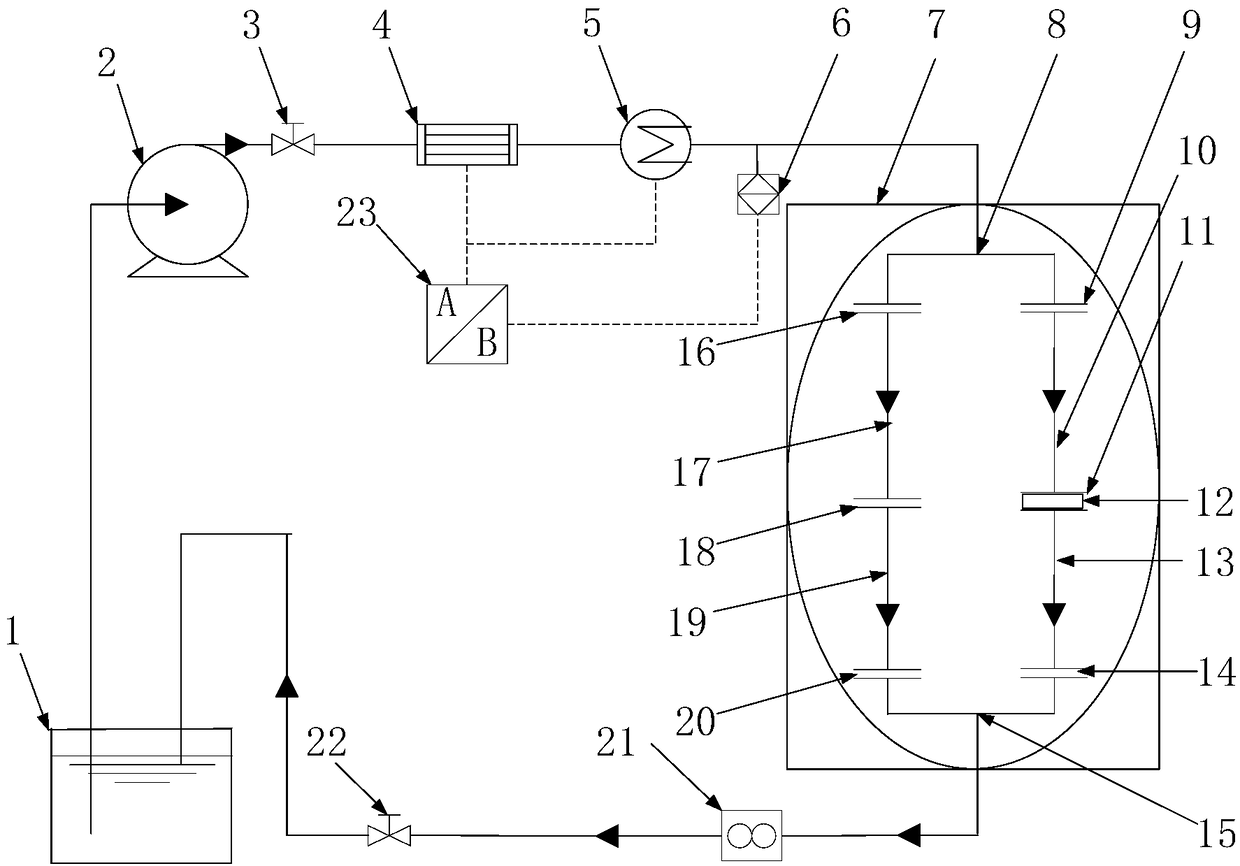

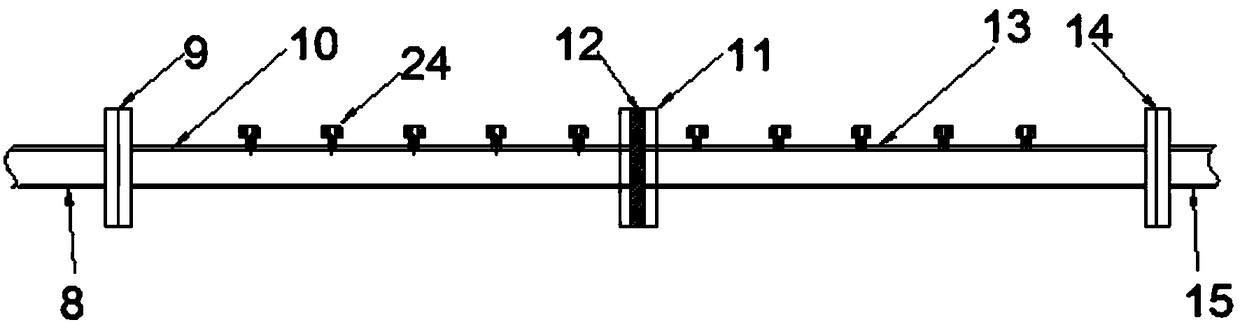

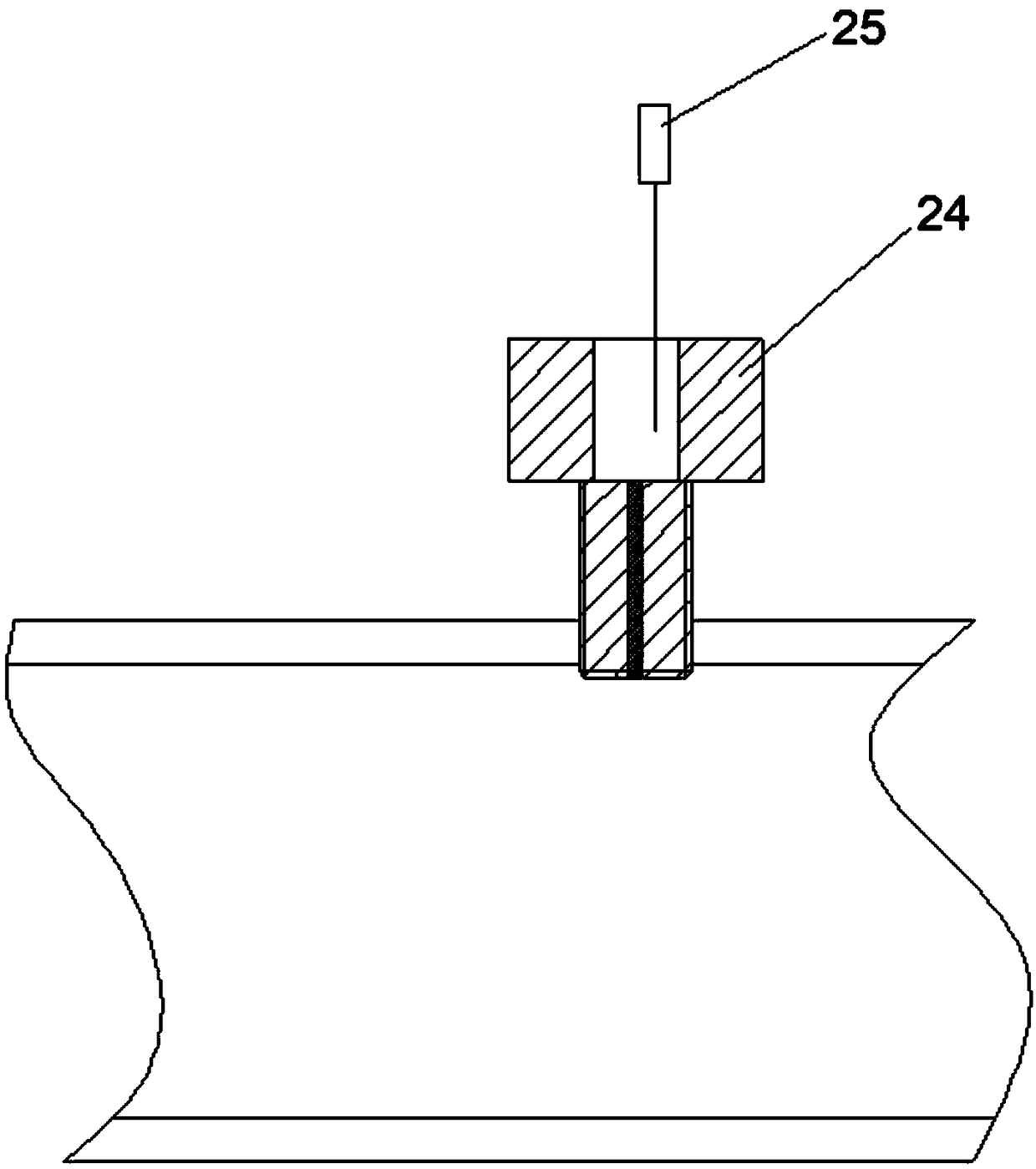

[0022] Such as figure 1 A test system for corrosion resistance of positive iron flanges of naval seawater pipelines is shown, including water storage tanks, centrifugal pumps, valves, chillers, electric heaters, temperature sensors, tee hoses, vibrating tables, flow meters, Temperature control panel and parallel positive iron flange corrosion resistance test section and corrosion comparison test section.

[0023] What flows in the whole circulation pipeline is the test seawater stored in the water storage tank. Preferably, the salinity of the test seawater can be adjusted.

[0024] Specifically, the temperature control panel controls the water chiller or the electric heater in the test pipeline system by comparing the input signal with the feedback signal output command of the temperature sensor.

[0025] The first three-way hose and the second three-way hose are extensions at both ends of the corrosion resistance test section and the corrosion comparison test section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com