Batch processing method for defect recognition of X-ray directional instrument

A defect recognition, batch processing technology, applied in character and pattern recognition, material analysis using radiation diffraction, instruments, etc., can solve problems such as system falling into local optimum and abnormal data powerlessness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Combined with the accompanying drawings, a technical scheme of a batch processing method for X-ray orientation instrument defect identification is described in detail, and the specific steps are as the overall process figure 1 Shown:

[0077] Step 1: Establish a sample library, including the data sample of the trochoidal curve of the standard single crystal crystal to be tested and each defect type, extract the feature vector of each trochoidal curve in the sample, and save the characteristics of each trochoidal curve of the sample vector, as a sample library;

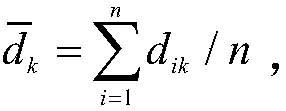

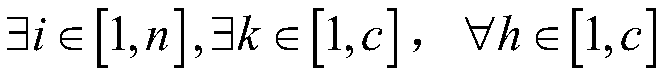

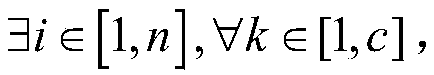

[0078] This application takes sapphire as an example, and provides three sample knowledge bases of crystals corresponding to standard crystals, edge dislocations and screw dislocations. Figure 4 , Figure 5 , Figure 6 As shown, the calculated eigenvectors are shown in the table below, where the eigenvector variables are defined as Figure 7 Shown:

[0079] Table 1 Pattern eigenvectors

[0080]

[0081...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com