A low-cost collaborative removal modeling and optimization method for pollutants in a coal-fired power plant

A technology for coal-fired power plants and optimization methods, which is applied in chemical instruments and methods, separation methods, electrostatic effect separation, etc. Model analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

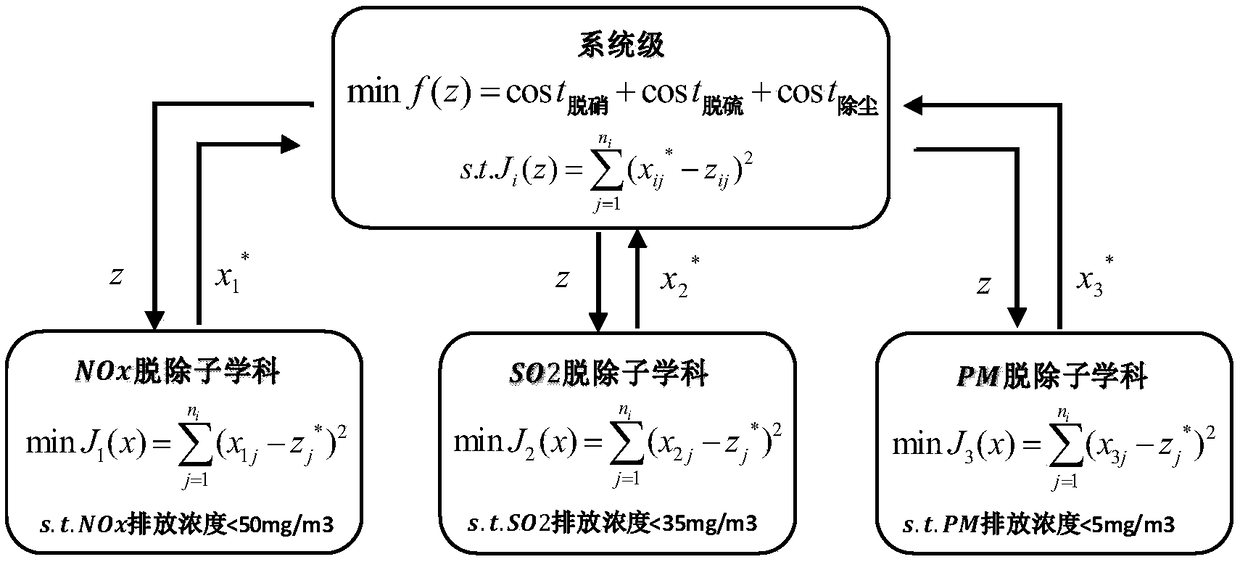

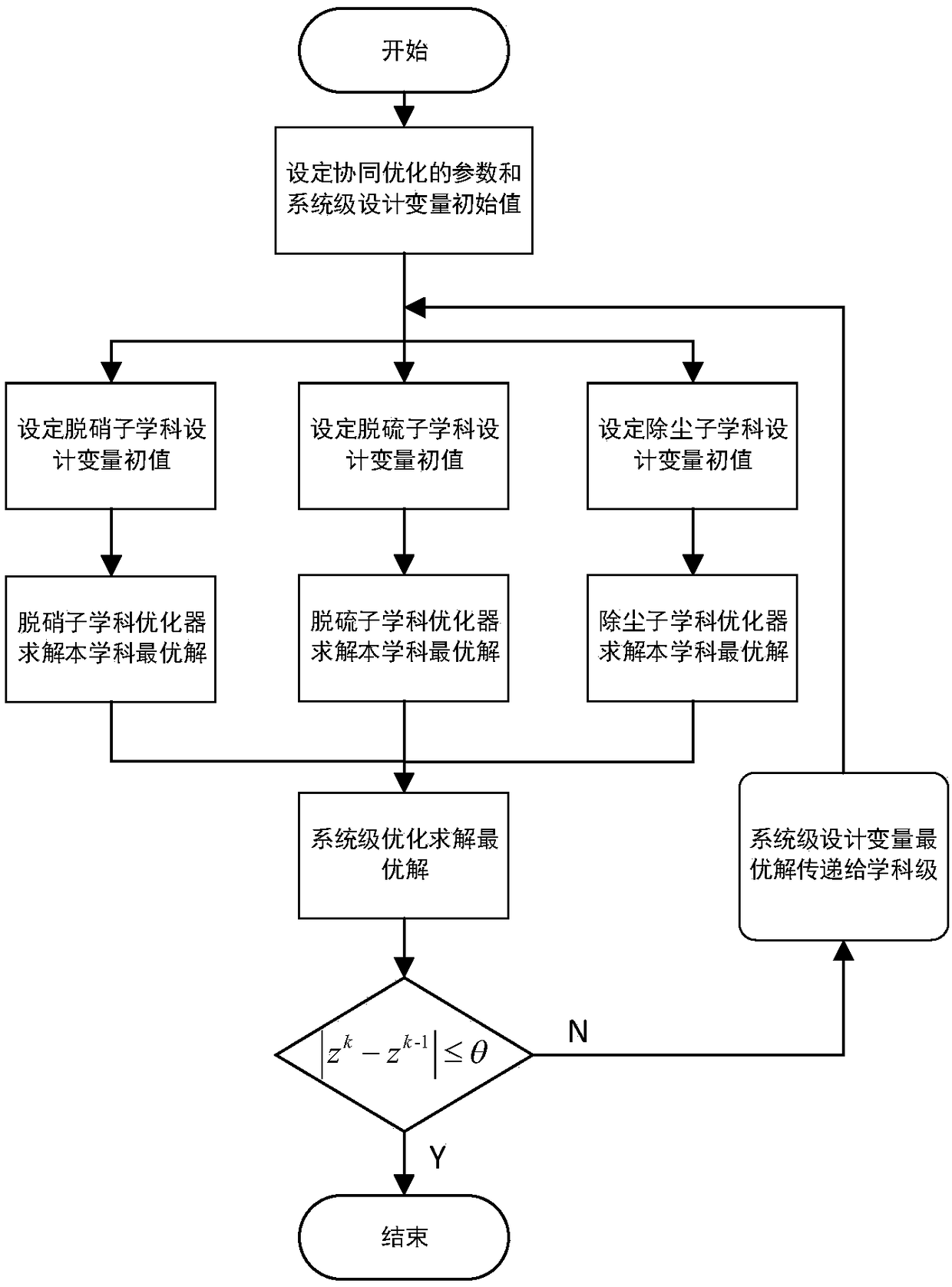

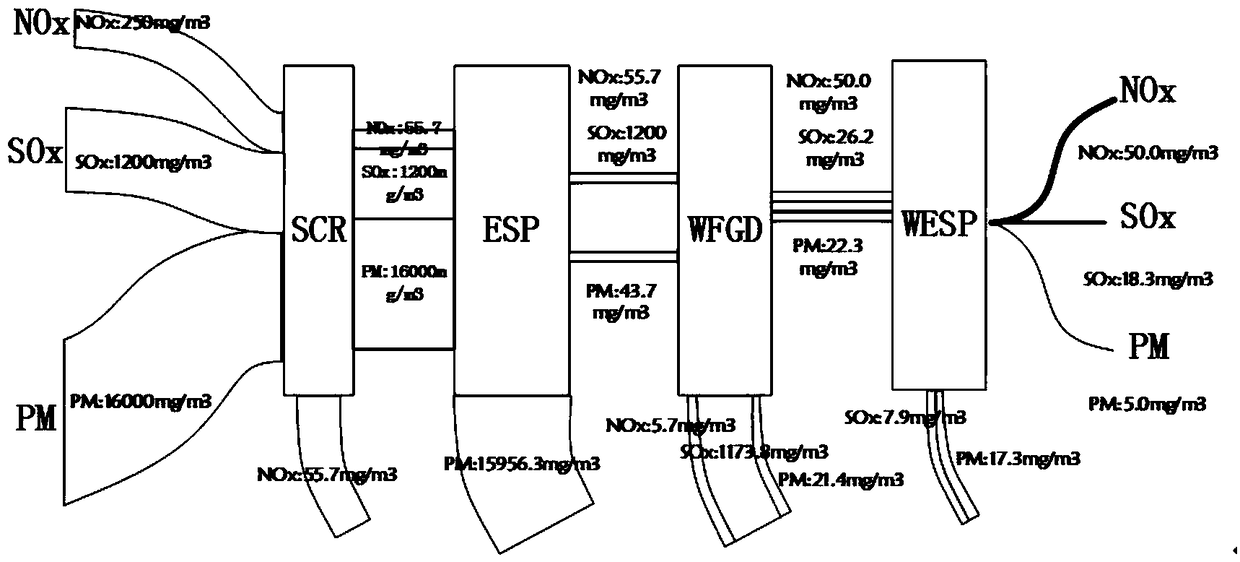

[0096]A low-cost collaborative removal modeling and optimization method for coal-fired power plant pollutants, for coal-fired power plant denitrification device SCR, dry electrostatic precipitator ESP, wet flue gas desulfurization device WFGD and wet electrostatic precipitator WESP, collect each pollutant The operating parameters and related variables of the pollutant removal device are analyzed to analyze the energy consumption and / or income generated in the process of pollutant removal, and establish the denitrification operation cost model, desulfurization operation cost model and dust removal operation cost model; establish pollutant collaborative removal The removal model includes three sub-discipline models and a system-level model; the three sub-discipline models are: denitrification sub-dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com