Low frequency broad-band gap 3D phonon crystal for vibration damping noise reduction

A phononic crystal, vibration reduction and noise reduction technology, applied in the direction of sound-emitting devices, instruments, etc., can solve the problems of large mass, complicated preparation, and difficulty in obtaining sufficient low-frequency wide bandgap, etc., to achieve weight reduction, simple preparation, and reduced size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, and the substantive features and remarkable progress of the present invention will be clarified.

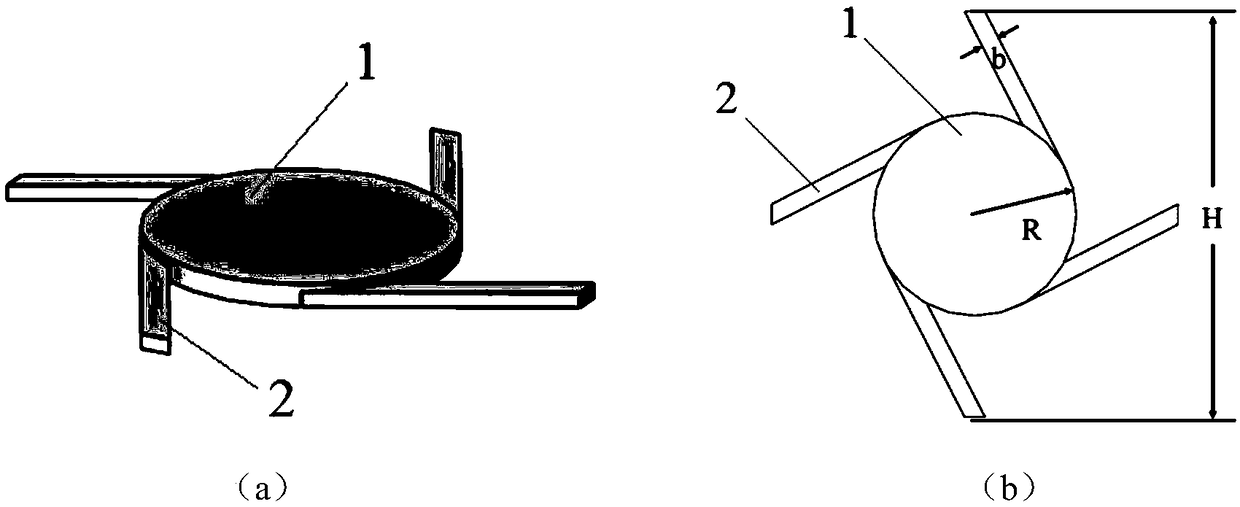

[0019] figure 1 (a) is the basic two-dimensional chiral structure in the unit cell model of the phononic crystal structure, including a disc 1 and four connecting rods 2 . Such as figure 1 As shown in (b), the axis of the connecting rod 2 is perpendicular to the axis of the disc 1, and the outer surface of one end of the connecting rod 2 is tangent to the side of the disc 1, and the four connecting rods 2 are distributed rotationally symmetrically around the disc 1 on the side of the disc structure. The disc 1 and the four connecting rods 2 are made of the same material, which is specifically determined by the acoustic characteristics and the requirements of the manufacturing process.

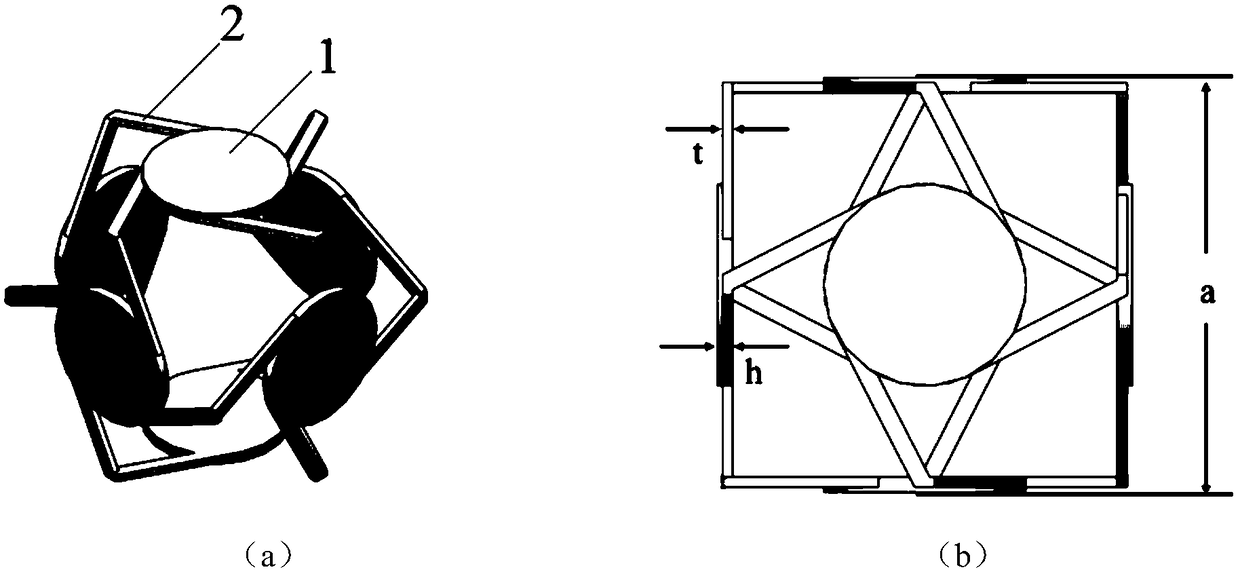

[0020] Six of the above-mentioned identical two-dimensional chiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com