One-step method for preparing metal oxide@chlorine-doped graphene lithium-ion battery anode materials

A lithium-ion battery, graphene technology, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of poor consistency of negative electrode materials, cumbersome methods, etc., and achieve the advantages of simple method, reduced preparation time, and good cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A method of preparing a metal oxide @ chlorine glycene graphene lithium ion battery in this example, wherein the preparation method is performed as follows:

[0046] Step 1, 0.4 g of oxide oxide (GO) was added to 20 mlN-methylpyrrolidone (NMP), stirred at 500 rpm at a rate of 20 kHz, and the ultrasonic frequency was ultrasonic for 1 h, and a uniform GO slurry was obtained;

[0047] Step 2, 0.375g SNCL 2 In 5 mlN-methylpyrrolidone (NMP), slowly added to the GO slurry, stirring at a rate of 500 rpm at a rate of 500 rpm, resulting in SNCL 2 @GO gel;

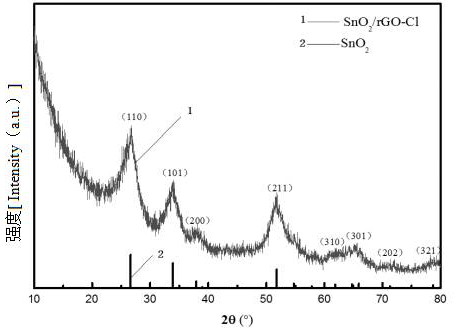

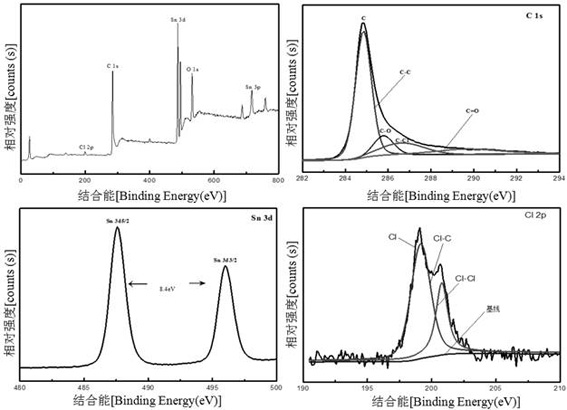

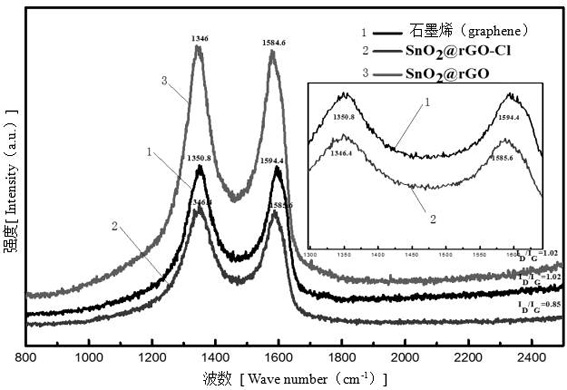

[0048] Step three, put SNCL 2 @GO gel is evenly coated on the copper foil (the film thickness is about 200 um), and after drying in a diameter of ф 12 mm, then place the tube furnace, 390 under argon. Calcination 2 h at ° C to give a lithium ion battery negative electrode material (SNO 2 @ RGO-CL negative material).

[0049] SNO prepared in this example 2 @ RGO-CL negative electrode material metal oxide SNO 2 For the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com