A stator laminated iron core of an axial flux motor and a manufacturing method thereof

A technology of motor stator and axial magnetic flux, which is applied in the manufacture of motor generators, stator/rotor bodies, magnetic circuits, etc., can solve the problems of motor insulation damage, the difficulty of ensuring the accuracy of the effective space of the formed iron core slot, etc. The effect of stable operation, eliminating the winding process and increasing the manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

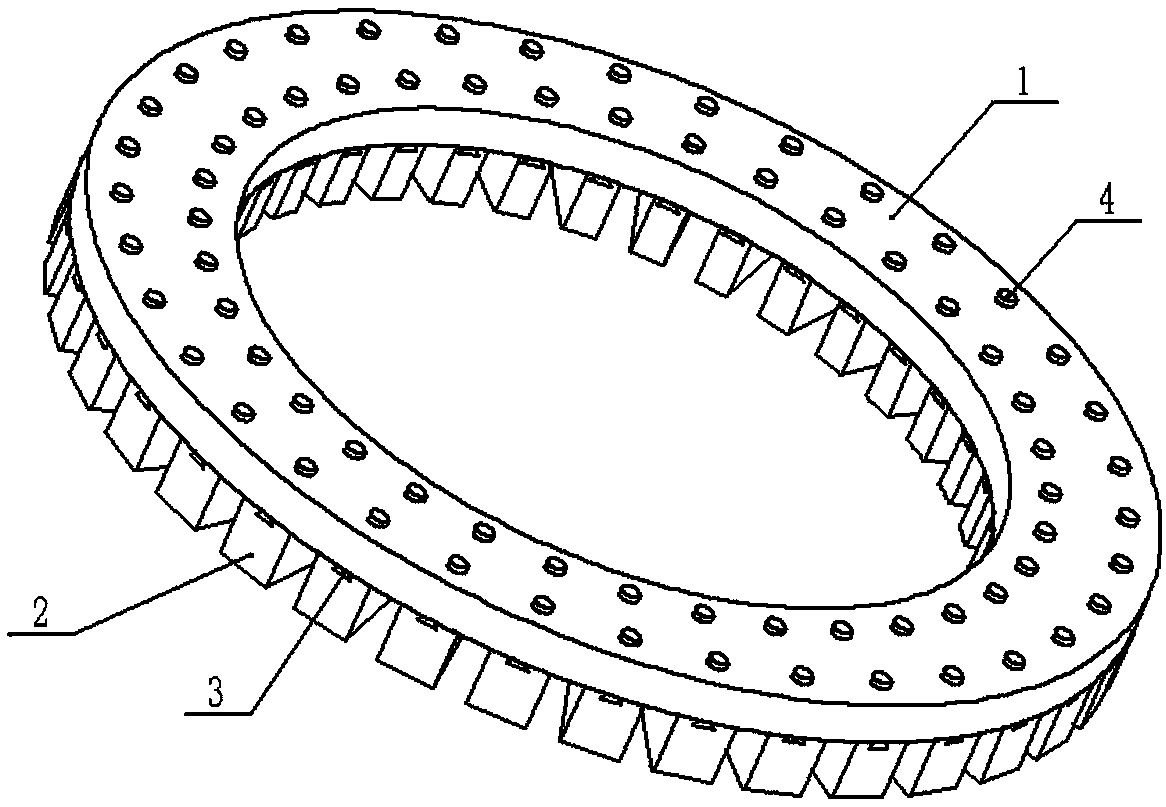

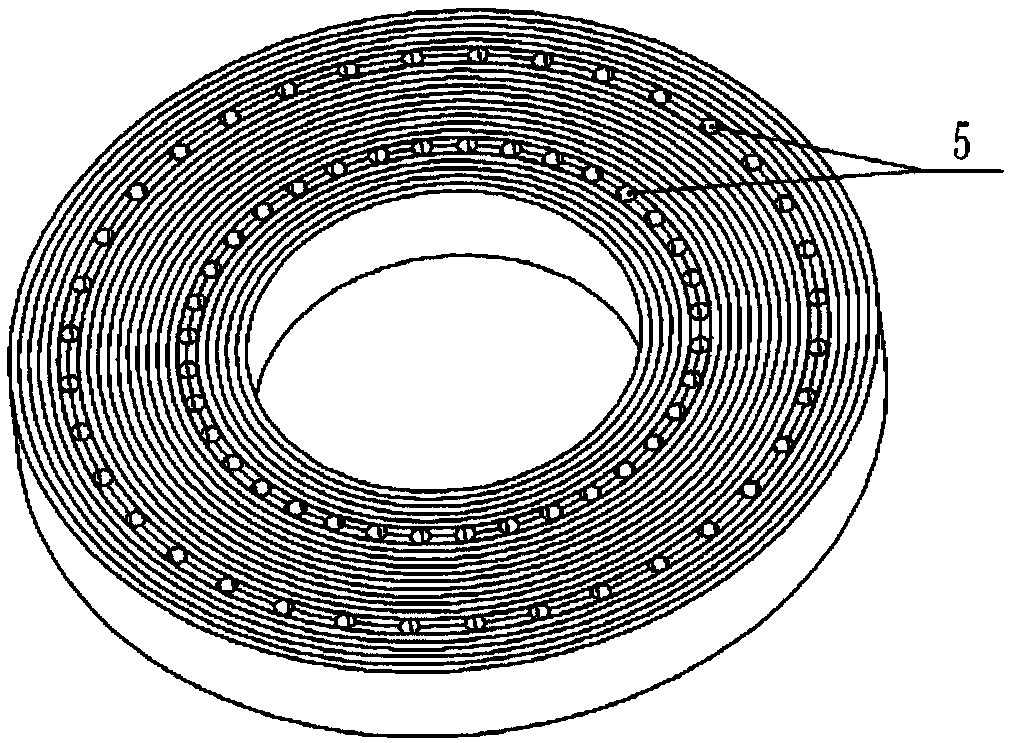

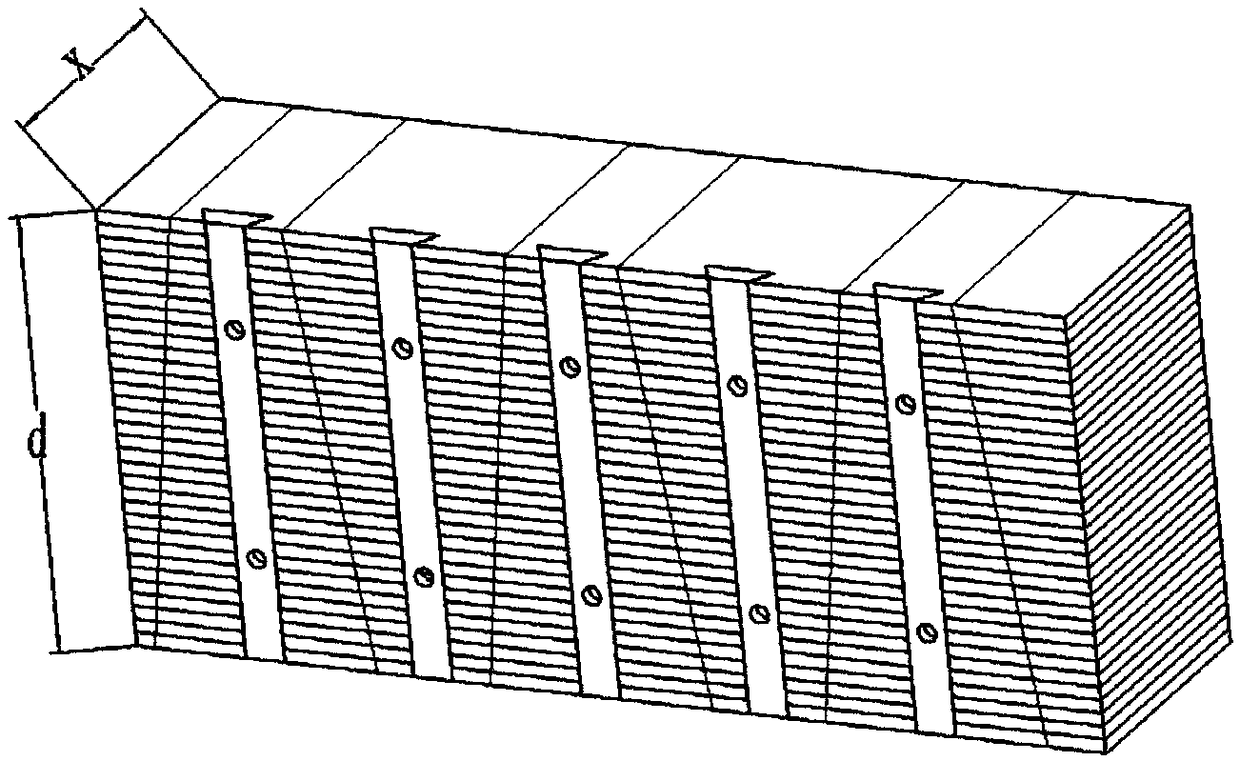

[0031] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a method for manufacturing a laminated iron core of an axial flux motor stator includes the following steps: In the first step, the punched sheet is rolled to form a stator yoke disk 1 . The stator yoke disk 1 is rolled from punched sheets and then compressed. The starting and ending positions of the punched sheets are fixed by welding. The stator yoke disk 1 is evenly distributed with tooth yoke connection holes 5 in the circumferential direction. In the second step, the punched sheets are stacked into cuboid block strips, and the stacked layers of the punched sheets are bonded with insulating varnish with bonding effect. The thickness of the cuboid block strip is half of the difference between the outer diameter and the inner diameter of the stator yoke disk 1 . Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com