Carbon-fiber heating sheet, production method and heating physiotherapy device

A carbon fiber heating sheet and carbon fiber heating technology are applied in the field of carbon fiber heating sheet and heating physiotherapy device, which can solve the problems of looseness, loose contact of carbon fiber, easy breaking of carbon fiber, etc., and achieve the effect of safe use, firm connection, and avoiding ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing:

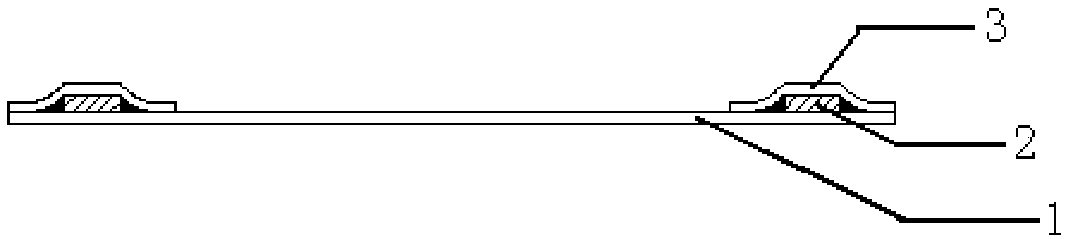

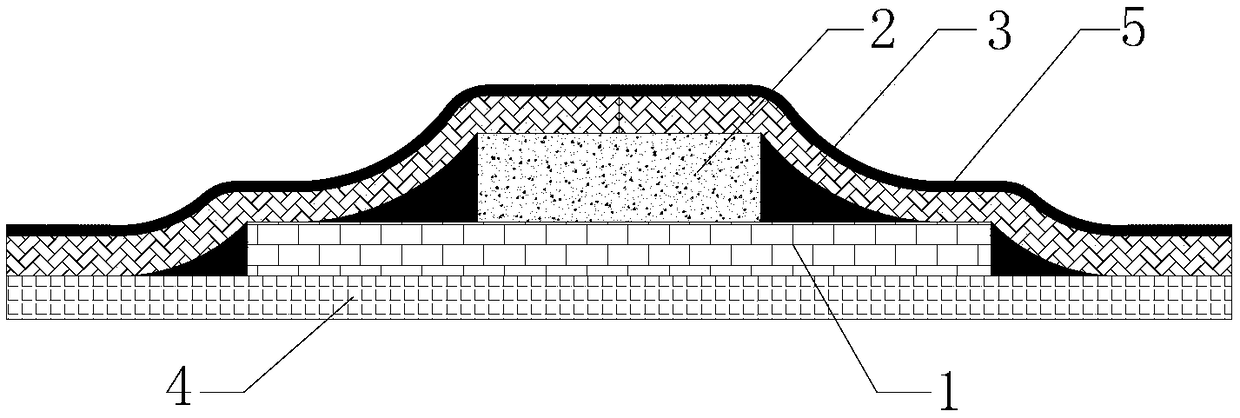

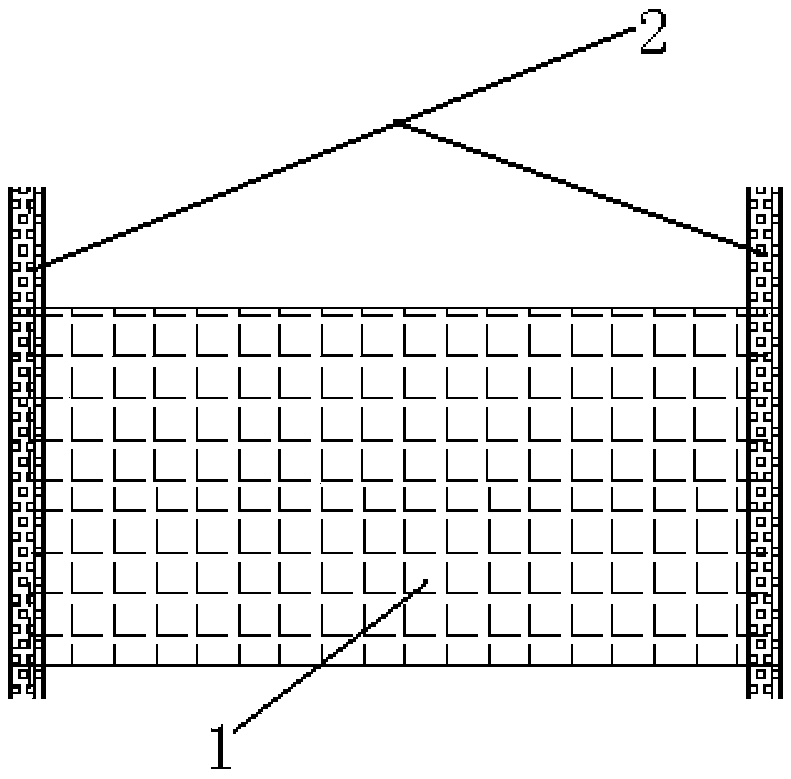

[0030] figure 1 , figure 2 A first embodiment of the invention is shown.

[0031] see figure 1 As shown, the carbon fiber heating sheet includes: a carbon fiber heating bundle 1 , an electrode strip 2 , and a conductive cloth 3 . Wherein, the electrode strip 2 can be one or any combination of the following flexible materials: tinned copper strips, tinned copper wires, and carbon-based conductive materials (such as flexible graphite, etc.). The electrode strip 2 is pasted on the carbon fiber heating bundle 1 with conductive glue (for example, silver glue, etc.), and is in electrical contact with the carbon fiber heating bundle 1, which can effectively avoid the phenomenon of the electrode strip 2 becoming loose, and reduces the noise caused by the carbon fiber heating sheet when it is energized. probability of fire. The part of the electrode strip 2 located w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com