Preparation method of meal replacement powder under vacuum environment

A production method and vacuum environment technology, applied in the field of health care, can solve the problems of graininess and poor digestion, and achieve the effects of easy digestion, full absorption and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the meal replacement powder under the vacuum environment, described meal replacement powder is made up of cereal, wheat and miscellaneous grains, and preparation method comprises the following steps:

[0034] (1) Weigh each component according to the weight of cereals, wheat, miscellaneous grains;

[0035] (2) Pour the weighed cereal components into the vacuum stir-frying machine, continue heating for 7 minutes, and wait for the expansion of the cereal components;

[0036] (3) Pour the weighed wheat components into the vacuum stir-frying machine, continue heating for 15 minutes, and wait for the expansion of the various components of the wheat;

[0037] (4) Pour the weighed miscellaneous grains components into the drying machine for baking, continue to dry for 3 hours, and wait for the water content of the miscellaneous grains components to be 5%-7%;

[0038] (5) Grinding and grinding the extruded cereal and wheat components respectively, and ...

Embodiment 2

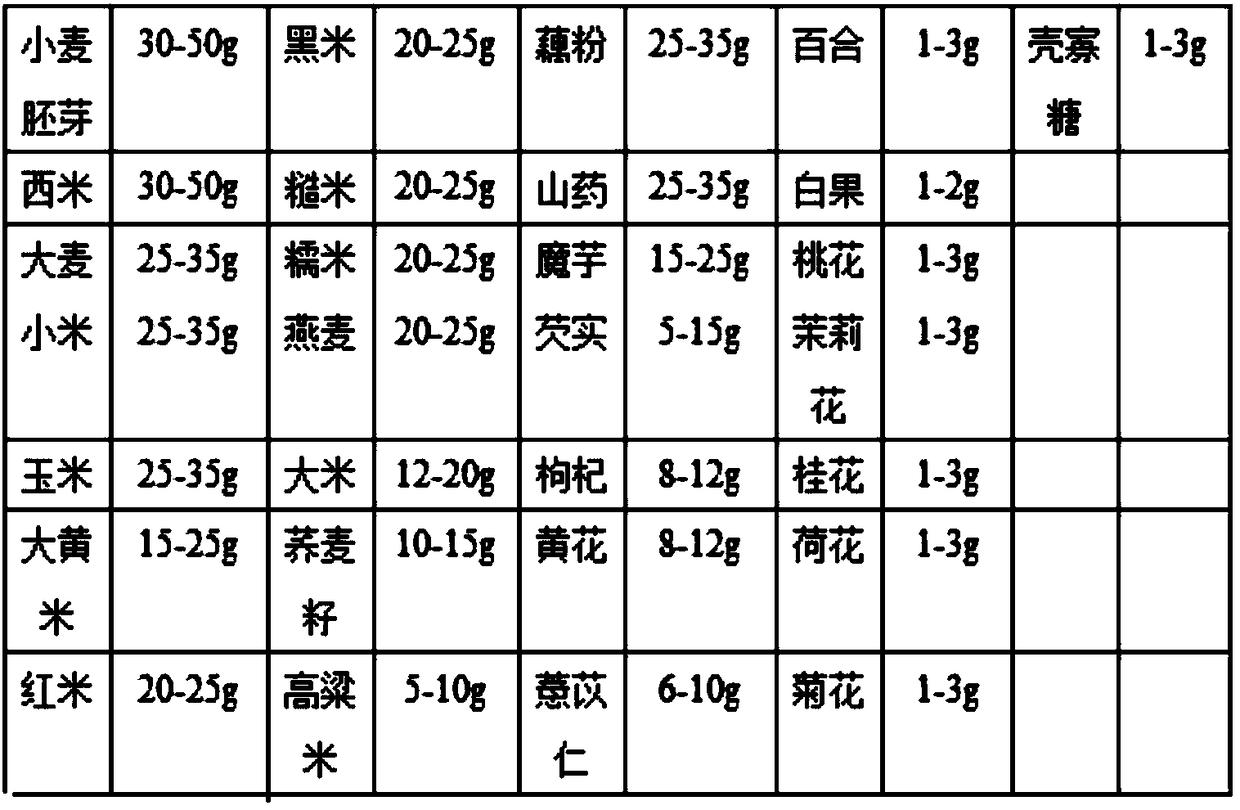

[0044] Such as figure 1 As shown, the difference between this embodiment and Example 1 is that the cereals, wheat and miscellaneous grains are composed of the following components, cereals: 30-50g of sago, 25-35g of millet, 15-25g of large yellow rice, red rice Rice 20-25g, black rice 20-25g, brown rice 20-25g, glutinous rice 20-25g, rice 12-20g, sorghum rice 5-10g, corn 25-35g

[0045] Wheat: 30-50g wheat germ, 25-35g barley, 20-25g oat, 10-15g buckwheat seed,

[0046]Miscellaneous grains: lotus root starch 25-35g, yam 25-35g, konjac 15-25g, gorgon fruit 5-15g, wolfberry 8-12g, yellow flower 8-12g, coix seed 6-10g, lily 1-3g, ginkgo 1-2g, peach blossom 1-3g, Jasmine 1-3g, Osmanthus 1-3g, Lotus 1-3g, Chrysanthemum 1-3g, Chitooligosaccharide 1-3g;

[0047] The values of the components of cereals, wheat and miscellaneous grains are as follows,

[0048] Cereals: 40g of sago, 30g of millet, 20g of large yellow rice, 22g of red rice, 22g of black rice, 22g of brown rice, 22g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com