Treatment technology of organic silicon slag slurry

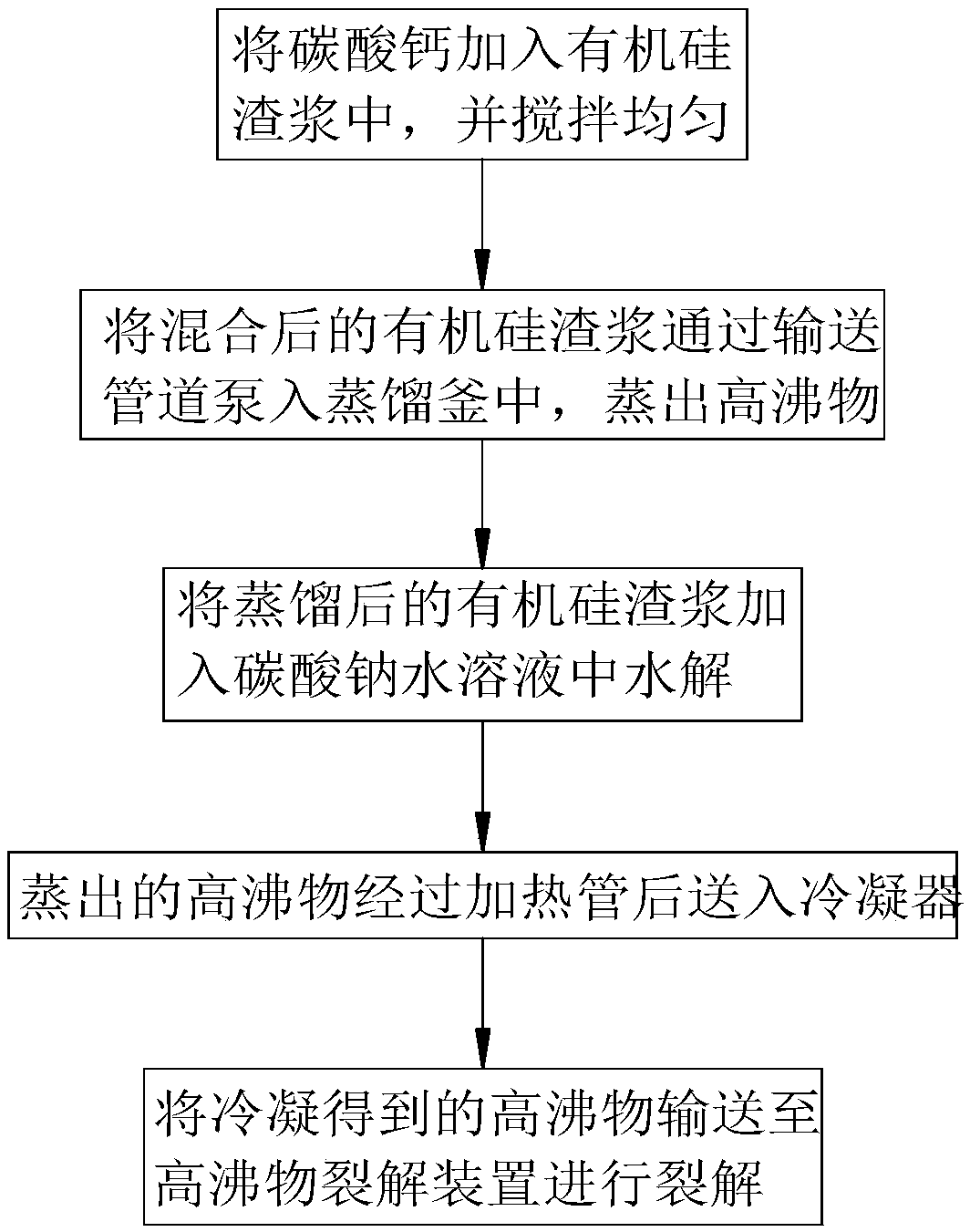

A technology for organosilicon slag slurry and treatment process, which is applied in the direction of protection devices against harmful chemicals, etc., can solve the problem of insufficient convection of organosilicon slag slurry, restricting the steaming efficiency of high-boiling substances, and low processing efficiency of organosilicon slag slurry, etc. problems, to achieve sufficient convection, increase flow paths, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

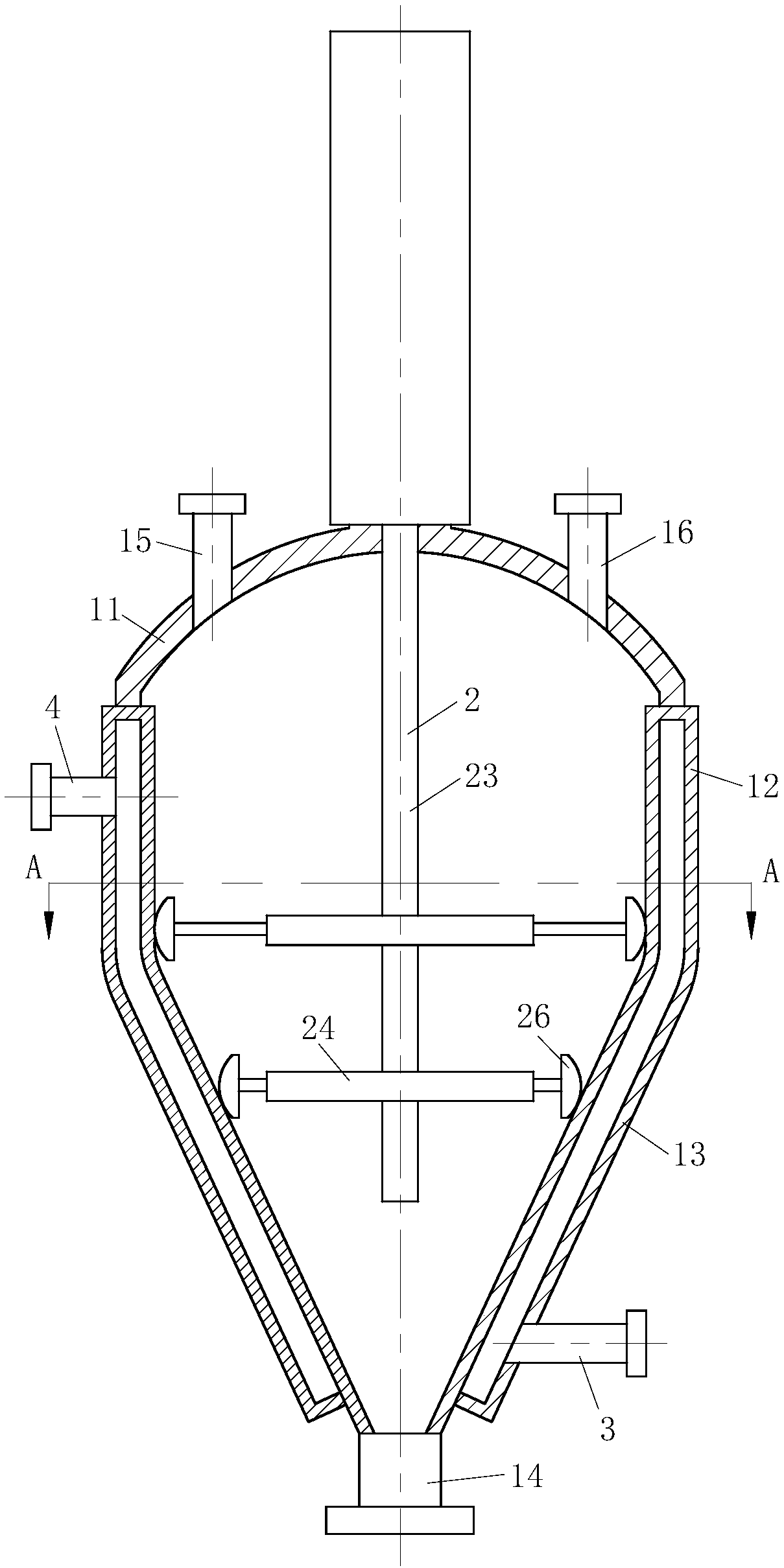

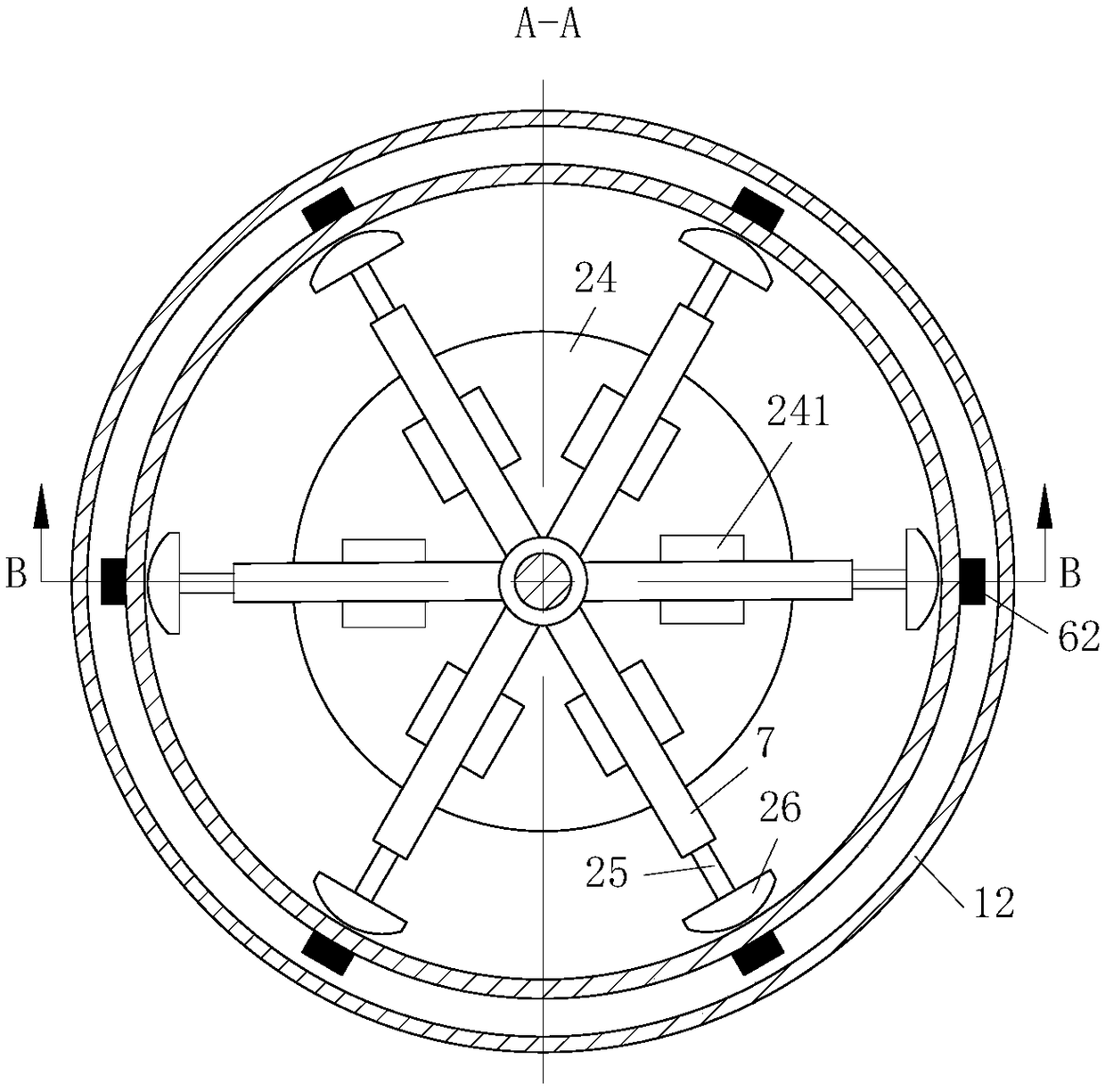

[0039] As an embodiment of the present invention, elastic steel wires 5 arranged crosswise are arranged in the notch 281, and the ends of the elastic steel wires 5 are fixedly connected to the inner wall of the notch 281. As the sliding plate 27 slides, the notch 281 opens , as the support plate 24 moves up and down, the elastic steel wire 5 shears the agglomerated material, which facilitates the subsequent slag discharge and improves the processing efficiency of the organic silicon slurry.

[0040] As an embodiment of the present invention, a first magnet 61 is provided inside the arc-shaped slider 26, and a first magnet 61 that is attracted to the first magnet 61 is provided in the interlayer of the cylindrical barrel 12 and the tapered barrel 13. Two magnets 62. The second magnet 62 slides along with the first magnet 61 to stir the heat transfer medium in the interlayer, increase the fluidity of the introduced medium, make the organic silicon slag heated evenly, and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com