Framework structure of detachable injection molding dragon lantern dragon ball

A technology of injection molding and skeleton structure, applied in auxiliary equipment for entertainers, devices for theaters, circuses, etc., entertainment, etc., can solve the problems of complex manufacturing process, high cost, and many processing steps, and achieve cost savings , the effect of improving manufacturing efficiency and easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Carry out detailed explanation below in conjunction with embodiment:

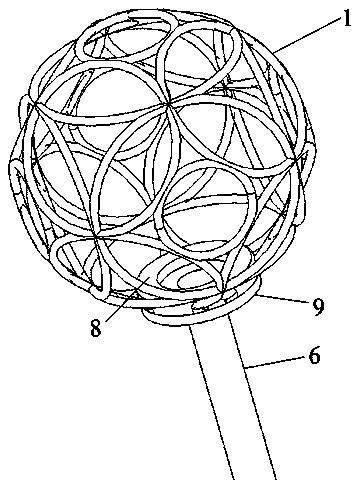

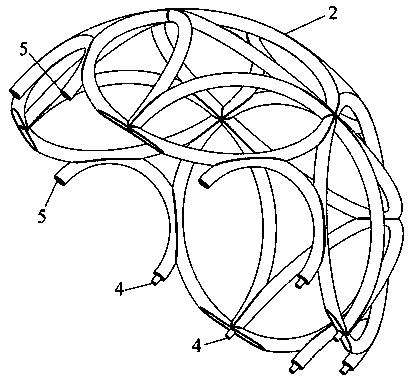

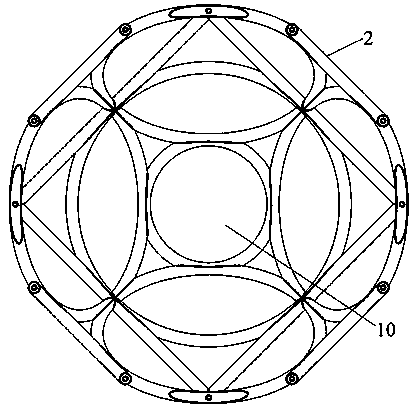

[0025] Such as Figure 1-8 As shown, a skeleton structure of a detachable injection-molded Dragon Ball Ball, including a ball 1 and a club connecting portion. Traditional bead balls are woven and bound with bamboo strips and iron wires. They are handmade products, which are not conducive to large-scale production and are very inconvenient to transport. Therefore, the sphere 1 described in this embodiment is formed by plastic injection molding. Considering the difficulty of demoulding the parts after injection molding (because the sphere 1 is a spherical structure, it is difficult to demould after one-time injection molding into a spherical shape), so the sphere 1 is designed as the first plastic hemispherical net 2 and the second plastic hemispherical net 3 spliced structures. Such as figure 2 As shown, in order to reduce the overall weight of the sphere 1 as much as possible, the first plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com