Method of sorting low grade uranium ores by dense medium cyclone

The technology of a heavy medium cyclone and a heavy medium cyclone is applied in the field of uranium ore sorting, which can solve the problems of difficulty in achieving tail throwing and low sorting accuracy, and achieve improved grade, high sorting accuracy and large processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

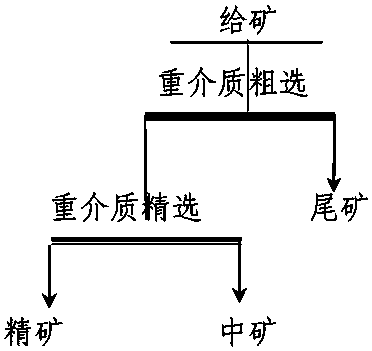

[0020] A method for sorting low-grade uranium ore with a dense medium cyclone, comprising the steps of:

[0021] (1) After coarse crushing and fine crushing, the raw ore is screened for a stage to obtain ore with a particle size of less than or equal to 5mm, and the ore with a particle size greater than 5mm is returned to fine crushing;

[0022] (2) The ore obtained in step (1) is subjected to secondary screening to obtain ore with a particle size range of 0.3-5mm, and the ore with a particle size of less than 0.3mm is treated as tailings;

[0023] (3) Send the ore with a particle size range of 0.3-5mm obtained in step (2) into a dense medium cyclone for separation. The heavy suspension in the dense medium cyclone effectively separates heavy minerals from light minerals, and They are discharged from their respective ore discharge outlets; the discharged heavy minerals and light minerals enter their respective de-intermediation and dehydration processes, and the heavy suspensio...

Embodiment 2

[0029] A method for sorting low-grade uranium ore with a dense medium cyclone, comprising the steps of:

[0030] (1) After coarse crushing and fine crushing, the raw ore is screened for a stage to obtain ore with a particle size of less than or equal to 5mm, and the ore with a particle size greater than 5mm is returned to fine crushing;

[0031] (2) The ore obtained in step (1) is subjected to secondary screening to obtain ore with a particle size range of 0.3-5mm, and the ore with a particle size of less than 0.3mm is treated as tailings;

[0032] (3) Send the ore with a particle size range of 0.3-5mm obtained in step (2) into a dense medium cyclone for separation. The heavy suspension in the dense medium cyclone effectively separates heavy minerals from light minerals, and They are discharged from their respective ore discharge outlets; the discharged heavy minerals and light minerals enter their respective de-intermediation and dehydration processes, and the heavy suspensio...

Embodiment 3

[0038] A method for sorting low-grade uranium ore with a dense medium cyclone, comprising the steps of:

[0039] (1) After coarse crushing and fine crushing, the raw ore is screened for a stage to obtain ore with a particle size of less than or equal to 5mm, and the ore with a particle size greater than 5mm is returned to fine crushing;

[0040] (2) The ore obtained in step (1) is subjected to secondary screening to obtain ore with a particle size range of 0.3-5mm, and the ore with a particle size of less than 0.3mm is treated as tailings;

[0041] (3) Send the ore with a particle size range of 0.3-5mm obtained in step (2) into a dense medium cyclone for separation. The heavy suspension in the dense medium cyclone effectively separates heavy minerals from light minerals, and They are discharged from their respective ore discharge outlets; the discharged heavy minerals and light minerals enter their respective de-intermediation and dehydration processes, and the heavy suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com