Blast furnace dust high-efficient separation and purification system and purification method

A sorting technology for blast furnace ash, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as waste of resources, dosing, and environmental pollution, and achieve less power equipment, realize utilization, and high-efficiency classification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

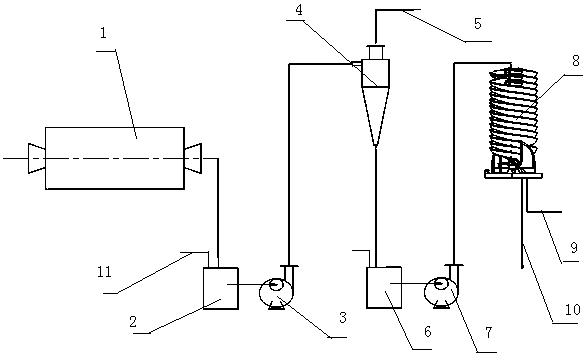

[0020] Below in conjunction with accompanying drawing, the present invention is further described:

[0021] As shown in the attached figure, a high-efficiency separation and purification system for blast furnace ash is characterized in that the system consists of a pulp making mechanism, a first-level homogeneous slurry conveying mechanism, a zinc extracting mechanism, a secondary homogenizing conveying mechanism, an iron-carbon extracting mechanism and a conveying mechanism. tube, the slurry-making mechanism is composed of a ball mill or a mixing tank 1, and the first-stage homogenizing conveying mechanism is composed of a homogenizing box 2 and a primary delivery pump 3, and the homogenizing box 2 is provided with an inlet Feed port and discharge port, the feed port on the homogenizing box 2 is connected with the discharge port of the ball mill or the mixing tank 1 through the conveying pipe, and the discharging port on the described homogenizing case 2 is connected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com