Technology for maintaining and heating of nodular cast iron pipe coated with cement lining before paint spraying

A nodular cast iron pipe and cement lining technology, which is applied to surface coating liquid devices, coatings, manufacturing tools, etc., can solve the problems of cement mottled lining, affecting the appearance quality of lining, and low internal grinding efficiency , to achieve the effect of improving appearance quality, avoiding cement cracking, and increasing internal grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

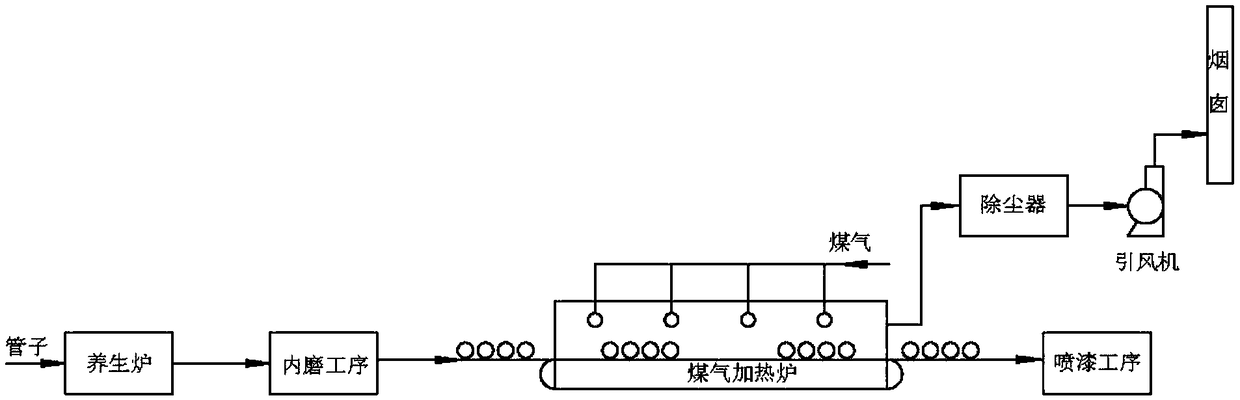

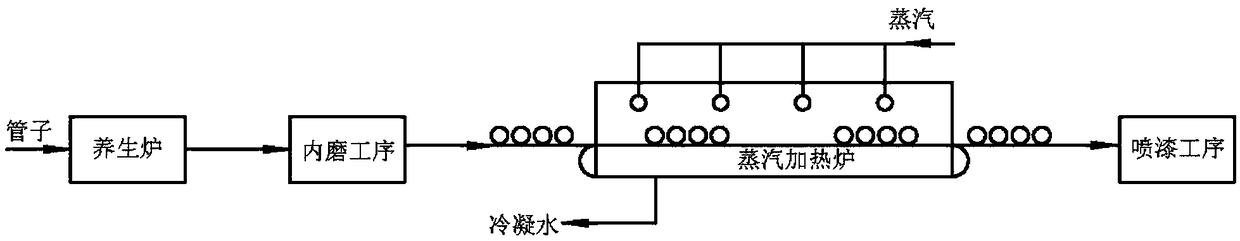

[0029] like figure 2 As shown, the health preservation and heating process of the ductile iron pipe coated with cement lining of the present invention and painting include: health preservation step, internal grinding step and heating step, and health preservation step comprises in turn: natural health preservation, low temperature health preservation and high temperature health preservation, it includes the following step:

[0030] (1) Natural health preservation: in winter, the ductile iron pipe is placed in the natural environment for 5 hours; in summer, the ductile iron pipe is placed in the natural environment for 4 hours;

[0031] (2) Low-temperature health preservation: place the ductile iron pipe coated with cement lining for 3 hours at a temperature of 40°C;

[0032] (3) High-temperature health preservation: place the ductile iron pipe coated with cement lining for 2 hours in an environment with a temperature of 60°C; make the cement lining strength reach about 80% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com