Wickerwork made by chitosan grafting modified wickers

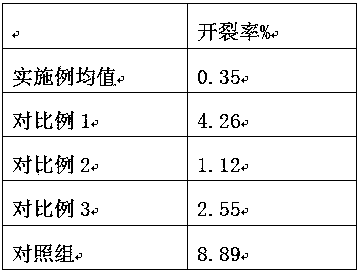

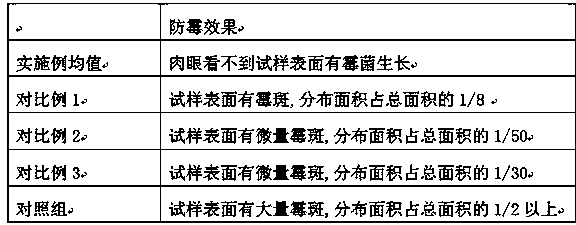

A graft modification and chitosan technology, applied in the field of willow weaving, can solve the problems of perishability, mildew, insects and the like, and achieve the effects of improving mildew resistance, slowing water absorption, and improving antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A chitosan graft-modified wicker-made wicker, comprising the following steps:

[0022] (1) Carboxylation treatment: The wicker and water are evenly mixed and soaked in a mass ratio of 1:12, heated to 40 ° C, and kept for 10 minutes, and then salicylic acid and acetic acid are added dropwise to the water in sequence, and the salicylic acid is added dropwise to the mass. is 5.2% of the water quality, and the dropwise addition quality of the acetic acid is 1.8% of the water quality, adjust the temperature to 55 ° C, keep the temperature for 40 min, then filter, use clean water to clean the wicker surface to neutrality, and air dry naturally;

[0023] (2) Preparation of grafting solution: The grafting solution is prepared by weight of the following components: 4.4 chitosan, 5.5 acetic acid, 0.3 amla amla extract, 10.0 ethanol, 2.5 vinyl dimethicone, Deionized water 60;

[0024] (3) Modification treatment: uniformly mix the treated wicker and the grafting liquid at a mass r...

Embodiment 2

[0034] A chitosan graft-modified wicker-made wicker, comprising the following steps:

[0035] (1) Carboxylation treatment: the wicker and water are evenly mixed and soaked in a mass ratio of 1:15, heated to 40 ° C, and kept for 10 min, and then salicylic acid and acetic acid are added dropwise to the water in sequence, and the salicylic acid is added dropwise to the mass. is 5.5% of the water quality, the acetic acid dripping quality is 2.3% of the water quality, adjust the temperature to 55 ° C, keep the temperature for 40 min, then filter, use clean water to clean the wicker surface to neutrality, and dry naturally;

[0036] (2) Preparation of grafting solution: The grafting solution is prepared by the following components in parts by weight: 4.6 chitosan, 6 acetic acid, 0.6 amla amla fruit extract, 12 ethanol, 2.9 vinyl dimethicone, Deionized water 70;

[0037] (3) Modification treatment: uniformly mix the above-treated wicker and grafting liquid in a mass ratio of 1:15-15...

Embodiment 3

[0047] A chitosan graft-modified wicker-made wicker, comprising the following steps:

[0048] (1) Carboxylation treatment: The wicker and water are evenly mixed and soaked in a mass ratio of 1:13, heated to 40 ° C, and kept for 10 minutes, and then salicylic acid and acetic acid are added dropwise to the water in sequence, and the salicylic acid is added dropwise to the mass. is 5.3% of the water quality, and the dropwise addition quality of the acetic acid is 1.9% of the water quality, adjust the temperature to 55 ° C, keep the temperature for 40 min, then filter, use clean water to clean the wicker surface to neutrality, and naturally dry it;

[0049] (2) Preparation of grafting solution: The grafting solution is prepared from the following components by weight: 4.5 chitosan, 5.6 acetic acid, 0.5 amla amla extract, 11 ethanol, 2.8 vinyl polydimethylsiloxane, Deionized water 65;

[0050] (3) Modification treatment: uniformly mix the treated wicker and the grafting liquid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com