Die truck loading system

A mold and support column technology, applied in the field of machinery, can solve the problems of easy falling of molds, vehicle wear, loud noise, etc., and achieve the effect of convenient mold loading, improved versatility and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

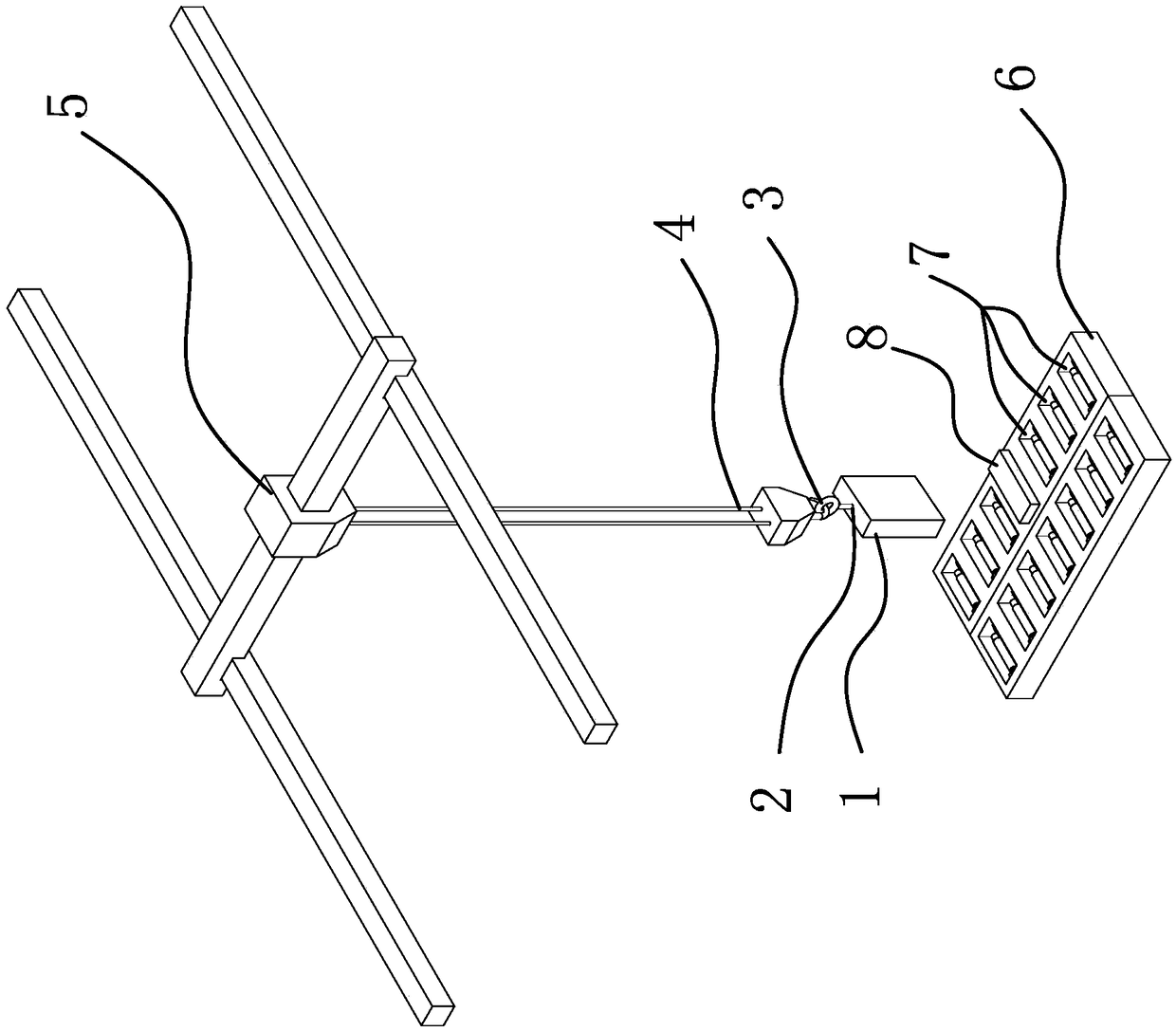

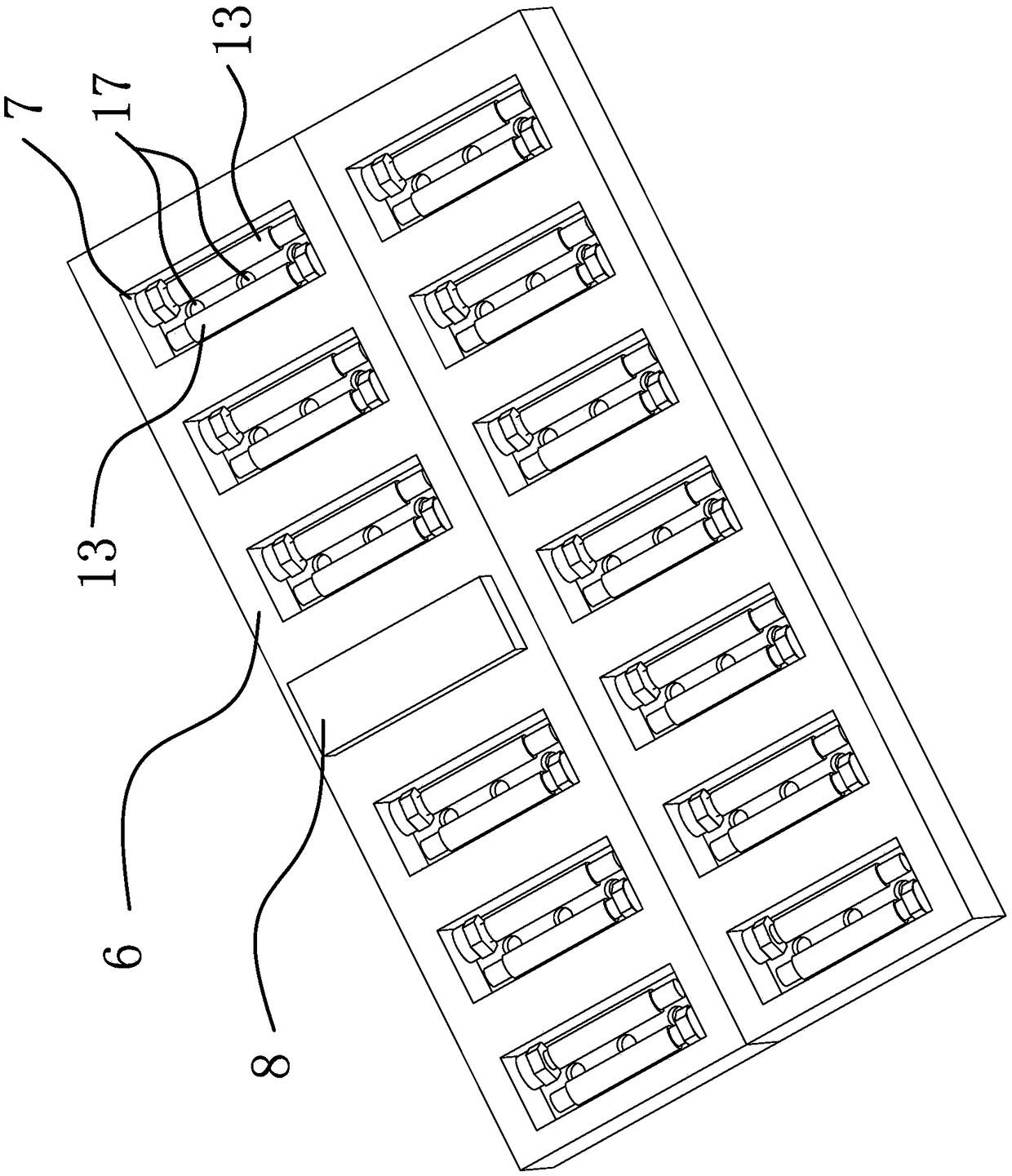

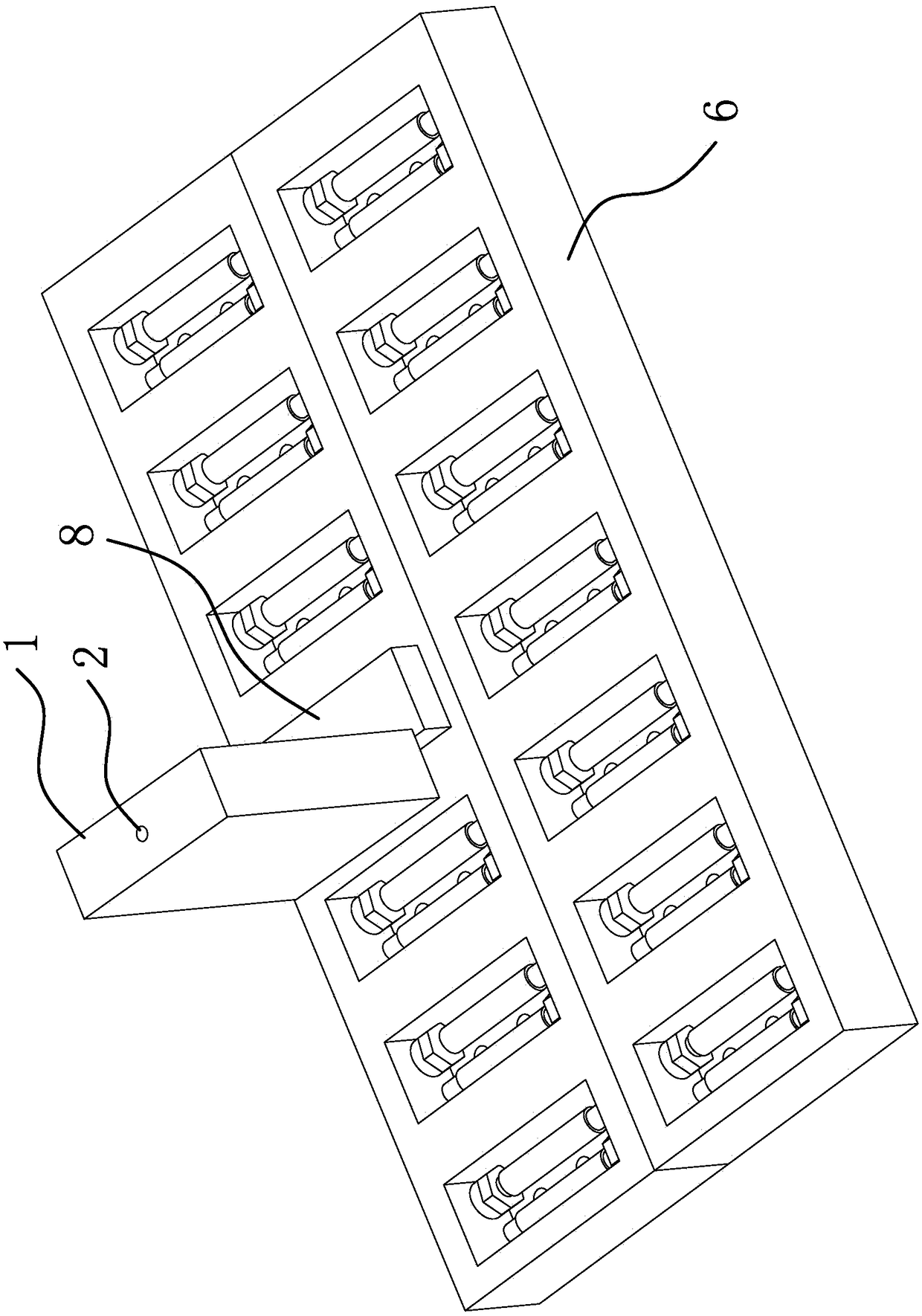

[0036] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the mold 1 is provided with a threaded hole-2, and it is characterized in that the loading system includes a bolt ring 3, a hook 4, a carriage 5 and a base plate 6, and the bolt ring 3 can be threadedly connected with the threaded hole-2 on the mold 1, The lower end of the hook 4 is fastened to the bolt ring 3, the upper end of the hook 4 is fastened to the carriage 5, the bottom plate 6 can be fixed on the compartment of the car, and the bottom plate 6 is provided with several slots 7 at intervals along its length direction and width direction. A spacer 8 is embedded in the slot 7 , and the upper surface of the spacer 8 is higher than the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com