Compound type reinforcing damping rubber sheet for automobile and preparation method thereof

A composite and reinforcing adhesive technology, which is applied in the direction of adhesive type, adhesive, epoxy resin glue, etc., can solve the problems of inability to achieve vibration reduction and noise reduction, and inability to achieve vehicle body reinforcement, so as to improve the safety of the vehicle body and market Broad application prospects and obvious energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

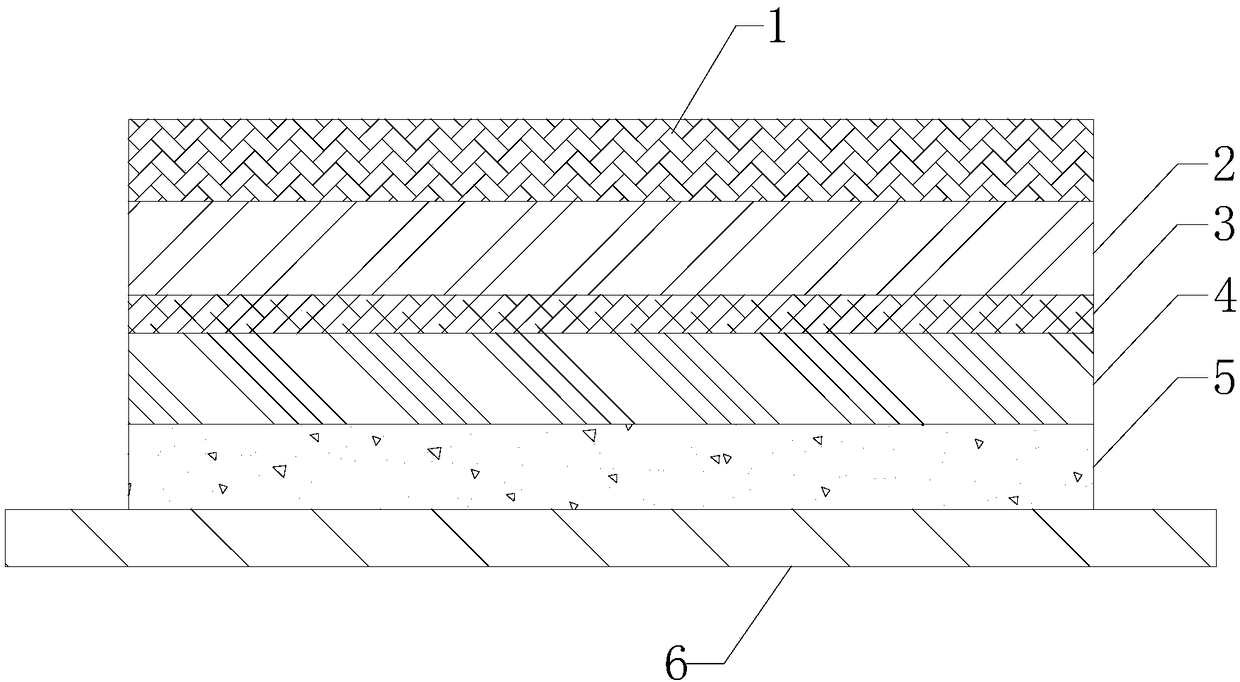

Image

Examples

Embodiment 1

[0033] Production and production examples of reinforced damping film:

[0034] Material ratio:

[0035] Damping adhesive layer 2 formula: 100 parts by weight of butyl rubber IIR1751, 30 parts by weight of polyisobutylene PB2400, 10 parts by weight of SEBS, 20 parts by weight of mica powder, 350 parts by weight of 800 mesh calcium carbonate, 15 parts by weight of EVA, loose 30 parts by weight of tar;

[0036] Reinforcing adhesive layer 5 formula: 20 parts of nitrile rubber NBR3604, 15 parts of tackifying rubber carboxylated nitrile rubber oil, 20 parts of epoxy resin E51, 50 parts of active filler 800 mesh calcium carbonate, 10 parts by weight of activated carbon , 5 parts of odorless curing agent.

[0037] Production process:

[0038] S1. Mastication: plasticize butyl rubber IIR1751 and nitrile rubber NBR3604, use an open mill to masticate butyl rubber and nitrile rubber 10 times at a temperature not exceeding 70°C, and place them for use. The roller pitch of the mill is 0...

Embodiment 2

[0047] Production and production examples of reinforced damping film:

[0048] Material ratio:

[0049] Damping adhesive layer 2 formula: 100 parts by weight of butyl rubber IIR1751, 15 parts by weight of polyisobutylene PB2400, 12 parts by weight of SEBS, 35 parts by weight of mica powder, 300 parts by weight of 800 mesh calcium carbonate, 16 parts by weight of EVA, loose 35 parts by weight of tar;

[0050] Reinforcing adhesive layer 5 formula: 25 parts of nitrile rubber NBR3604, 15 parts of tackifying rubber carboxylated nitrile rubber oil, 30 parts of epoxy resin E51, 40 parts of active filler 800 mesh calcium carbonate, 6 parts of coconut shell activated carbon parts by weight, 5 parts of odorless curing agent.

[0051] Production process:

[0052] S1. Mastication: plasticize butyl rubber IIR1751 and nitrile rubber NBR3604, use an open mill to masticate butyl rubber and nitrile rubber 10 times at a temperature not exceeding 70°C, and place them for use. The roller pitc...

Embodiment 3

[0061] Production and production examples of reinforced damping film:

[0062] Material ratio:

[0063] Damping adhesive layer 2 formula: 100 parts by weight of butyl rubber IIR1751, 10 parts by weight of polyisobutylene PB2400, 13 parts by weight of SEBS, 25 parts by weight of mica powder, 250 parts by weight of 800 mesh calcium carbonate, 12 parts by weight of EVA, loose 25 parts by weight of tar;

[0064] Reinforcing adhesive layer 5 formula: 30 parts of nitrile rubber NBR3604, 10 parts of tackifying rubber carboxylated nitrile rubber oil, 25 parts of epoxy resin E51, 25 parts of active filler 800 mesh calcium carbonate, 5 parts of coconut shell activated carbon parts by weight, 10 parts of odorless curing agent.

[0065] Production process:

[0066] S1. Mastication: plasticize butyl rubber IIR1751 and nitrile rubber NBR3604, use an open mill to masticate butyl rubber and nitrile rubber 10 times at a temperature not exceeding 70°C, and place them for use. The roller pit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com